Equipment component

|

10 ton Hydraulic single-arm uncoiler, hydraulic feeding trolley, support arm

|

1

|

|

15-axis four-Layer precision leveling machine

|

1

|

|

Rectify device

|

1

|

|

Nine-roller servo-straighten machine

|

1

|

|

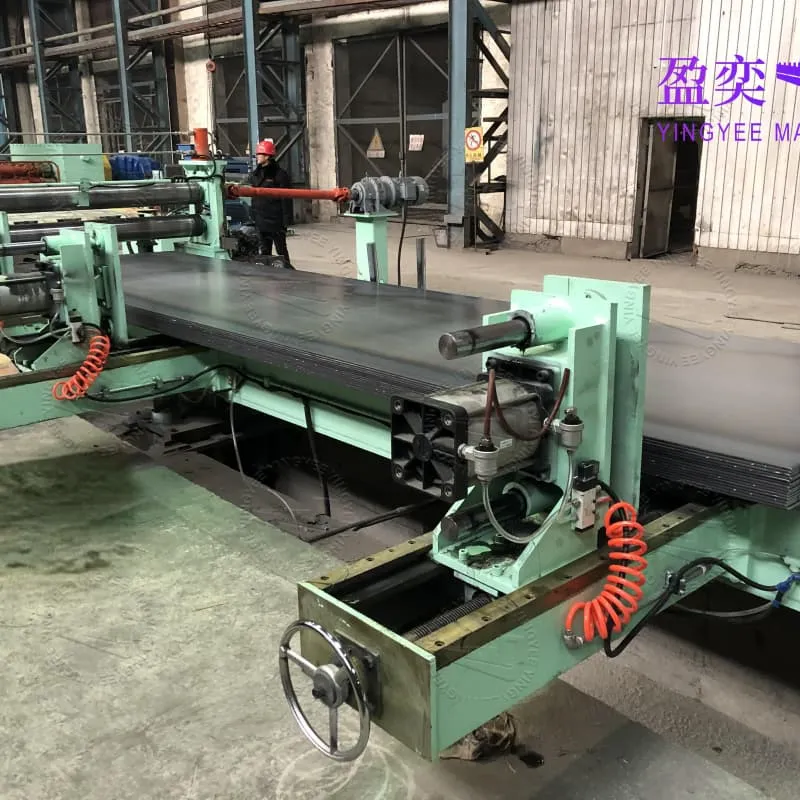

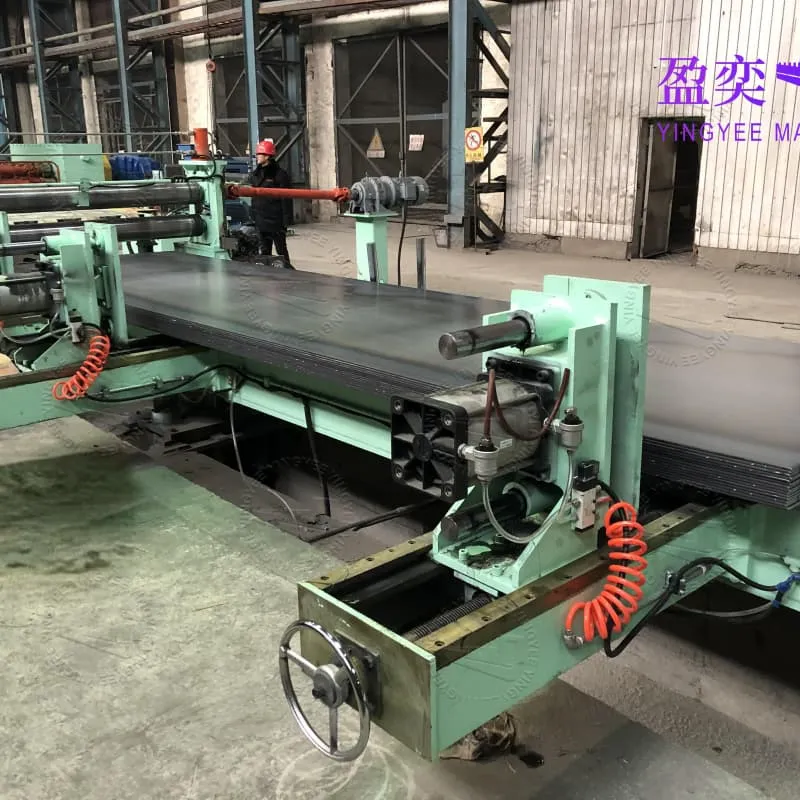

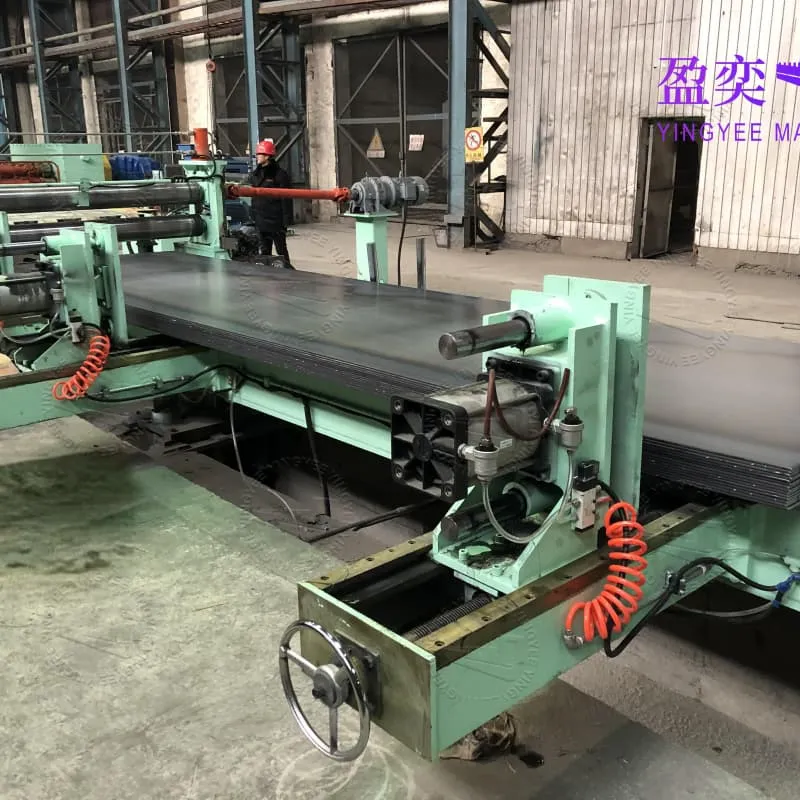

High-speed pneumatic shearing machine

|

1

|

|

Two-section structure conveyor belt

|

1

|

|

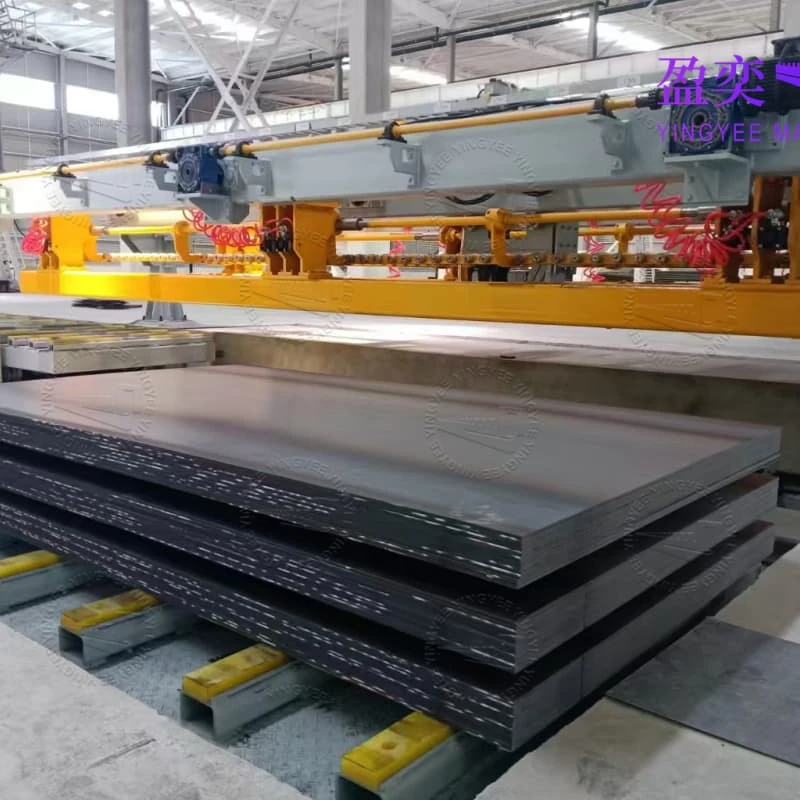

Automatic hydraulic stacker and lifting machine

|

1

|

|

Outting sheet platform 6000mm

|

1

|

|

Electronic control system

|

1

|

|

Hydraulic oil station

|

1

|

|

Fan

|

1

|

|

|

2. Equipment specifications and main technical parameters

1.1 Production line specifications 0.4-3.0×1250mm

1.2 Uncoiling width range 500-1250mm

1.3 Material thickness 0.4-3.0mm

1.4 Frame material Q235

1.5 Maximum roll weight 10T

1.6 Inner diameter of steel coil 508-610mm

1.7 Outer diameter of steel coil ≤1700mm

1.8 Production line speed 55-58m/min

1.9 Cutting frequency 25-28 sheets (1000×2000mm shall prevail)

1.10 Cutting length range 500-6000mm

1.11 Sizing accuracy ±0.5/mm

1.12 Diagonal accuracy ±0.5/mm

1.13 Total power ≈85kw (normal working power 75kw)

1.14 Unwinding direction facing the console from left to right

1.15 Unit area ≈25m×6.0m (used as standard)

1.16 power supply 480v/50hz/3 phase

3. Details Parameters

1 Hydraulic single arm decoiler

- Structure

This machine is a single-head cantilever hydraulic expansion and contraction decoiler, which is composed of a main shaft part and a transmission part.

(1) The main shaft part is the core part of the machine. Its four segments are connected to the sliding sleeve through T-shaped inclined blocks and are sleeved on the hollow main shaft at the same time. The core is connected with the sliding sleeve. The fan block expands and contracts at the same time. When the fan block is contracted, it is beneficial to roll up, and when the fan block is opened, the steel coil is tightened to complete the unwinding.

(2) The pressure roller part is located behind the uncoiler. The pressure arm can drive the cantilever to press down and pick up under the control of the oil cylinder. When feeding, press down the cantilever pressure roller to press the steel coil, which can prevent loose coils and facilitate feeding.

(3) The transmission part is located outside the frame, and the main shaft of the uncoiler is driven to rotate by the motor and the reducer through the gear, which can also realize the positive and negative uncoil and rewind.

- Main technical parameters:

(1) Maximum load: 10 tons

(2) Steel coil inner warp: ¢508-610mm inner warp.

2 Hydraulic loading car

- Structure

It is mainly composed of a car disc, a cylinder seat, an oil cylinder and a traveling system. When working, put the steel plate on the top of the oil cylinder at the position of the trolley tray. The oil cylinder lifts the steel plate to the height of the decoiler. The motor is started to move to the center of the decoiler. The decoiler tightens the steel coil and the loading car rolls along the track. Return to the feeding area.

- technical parameter

(1) Coil width: 500mm-1500mm

(2) Coil weight: 15T

(3) Oil cylinder stroke: 600mm

(4) Hydraulic motor travel

3 15-axis four-Layer precision leveling machine

Number of leveling rollers 15 axes

Diameter of leveling roller 120mm

Leveling roller material 45cr

Motor power: 30kw (Guomao reducer 160 type)

Form: Quadruple type. Pinch the upper roller to encapsulate, and the cylinder performs lifting.

Leveling roller: The material of the leveling roller is 45cr, after quenching and tempering, quenching and grinding, the surface hardness reaches HRC52-55, and the surface finish is Ra1.6mm. There are two rows of auxiliary support rollers (support roller material No. 45), and the upper row of work rollers are vertically moved up and down by motor drive.

The bearing of the work roll adopts rolling bearing, which has a bearing capacity and a long service life.

The main force system: a motor is centrally driven, driven by the universal coupling of the reducer transmission box.

4 Guide centering device

Vertical guide roller guide. Manually adjust the distance between the two measuring guide rollers.

5 Nine-roller servo-straighten machine: All rollers are covered with rubber

Number of feeding rollers: 9 rollers

Leveling roller diameter 120mm

Fixed-length roller diameter 160mm

Work roll material No. 45

Servo motor: 11kw

6 High-speed pneumatic shearing machine:

It is mainly composed of left and right brackets, connecting rods, upper and lower tool rests, worktables, drive motors and other parts, and can be selected according to user requirements.

(1) Maximum cutting thickness: 3mm

(2) Cutting width: 1250mm

(3) Motor power: 11KW

7 Conveyor belt:

8 Automatic hydraulic stacker and lifting machine (note: the lifting part is 6000mm, the gas is from the equipment) structure:

The blanking machine mainly performs the neat blanking of the sheets, and consists of a horizontally moving frame and a longitudinal baffle. The horizontal movement frame is adjusted manually according to different board widths, and the longitudinal baffle is adjusted according to different board lengths. The palletizing machine is mainly composed of a palletizing cylinder walking roller table and a motor. Its function is to neatly stack the blanked boards obliquely.

The main technical parameters:

(1) The height of the blanking rack: 2100mm

(2) Total length of blanking rack: about 6300mm Total width: 2600mm

(3) Load-bearing capacity of blanking rack: 6000kg