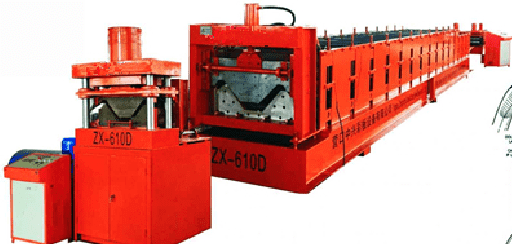

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Aýratynlyklary

1.1 Rolikler, ýalpyldawuk gaýtadan işlenen gowy ak polatdan ýasalýar.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Taýýar reňk gaty uly aralyk, ýokary gasyn, ýokary dartyş güýji bolar.

2. Esasy tehniki maglumatlar YY-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Göni panel bölekleriniň ululygy: 10000 mm x 1400 mm x 1600 mm

Egilme paneliniň ululygy: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Jemi agramy: takmynan 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Formanyň güýji: 7.5kw

6. Egilme güýji: 7.5kw

7. Kesiş güýji: 3.0kw

8. Nebit nasosynyň hereketlendiriji güýji: 7.5kw

9. Rolikleriň materialy: 45 # polat, söndürilen HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Kesmek üçin material: Cr12Mov polat

12. Step of rollers: 16 steps

13. Iýmitlendiriş giňligi: 1000mm.

14. Effective Width: 680mm as drawing

15. Bobanyň galyňlygy: 0,6-1,6mm

16. Çukuryň çuňlugy: çyzgylara görä

17. iň ýokary aralyk: 42 m

18. Paneliň işleýiş faktory: 64%