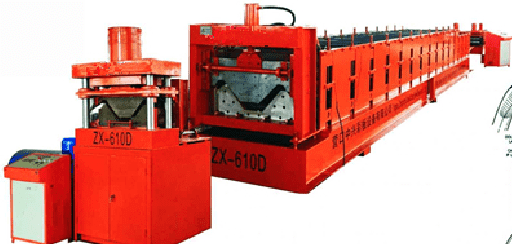

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Awọn ẹya ara ẹrọ

1.1 Rollers ti wa ni ṣe ti o dara funfun irin ni ilọsiwaju pẹlu polishing.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Awọ ti o pari yoo jẹ igba ti o tobi pupọ, corrugation giga, agbara ẹdọfu giga.

2. Main imọ data ti YY-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Iwọn apakan nronu taara: 10000 mm x 1400 mm x 1600 mm

Iwọn apakan apakan nronu: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Apapọ iwuwo: Nipa 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Ṣiṣẹda Agbara: 7.5kw

6. Titẹ Agbara: 7.5kw

7. Ige Agbara: 3.0kw

8. Agbara fifa epo epo: 7.5kw

9. Ohun elo ti rollers: 45 # irin, pa HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Ohun elo ti gige abẹfẹlẹ: Cr12Mov irin

12. Step of rollers: 16 steps

13. Iwọn Ifunni: 1000mm.

14. Effective Width: 680mm as drawing

15. Sisanra ti okun: 0.6-1.6mm

16. Awọn ijinle iho: gẹgẹ yiya

17. ipari ti o pọju: 42 m

18.Operating ifosiwewe ti nronu: 64%