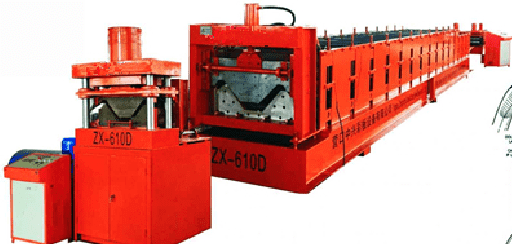

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Astaamaha

1.1 Rollers waxay ka samaysan yihiin bir cad oo wanaagsan oo lagu farsameeyey sifaynta.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Midabka la dhammeeyey wuxuu noqon doonaa taako aad u weyn, jiingado sare, xoog kacsanaan sare leh.

2. Xogta ugu weyn ee farsamada ee YY-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Cabbirka guddi toosan: 10000 mm x 1400 mm x 1600 mm

Laacidda qaybta cabbirka: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Wadarta miisaanka: Qiyaastii 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Samaynta Awoodda: 7.5kw

6. Laacidda Awoodda: 7.5kw

7. Goynta Awoodda: 3.0kw

8. Awoodda mashiinka bamka saliidda: 7.5kw

9. Qalabka rollers: 45#birta, bakhtiiyay HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Qalabka goynta goynta: Cr12Mov steel

12. Step of rollers: 16 steps

13. Ballaca Quudinta: 1000mm.

14. Effective Width: 680mm as drawing

15. Dhumucda gariiradda: 0.6-1.6mm

16. Qoto dheer ee godka: sida sawirada

17. dhererka ugu badan: 42 m

18.Qaybta hawlgelinta guddiga: 64%