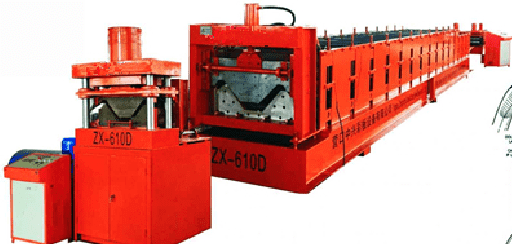

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Likarolo

1.1 Lirolara li entsoe ka tšepe e ntle e tšoeu e entsoeng ka ho belisoa.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 'Mala o feliloeng e tla ba span e kholo haholo, corrugation e phahameng, matla a phahameng a tsitsipano.

2. Lintlha tse ka sehloohong tsa tekheniki tsa YY-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Boholo ba karolo e otlolohileng: 10000 mm x 1400 mm x 1600 mm

Karolo ea boholo ba phanele: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Kakaretso ea boima ba 'mele: Hoo e ka bang 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Ho theha Matla: 7.5kw

6. Matla a Kobehang: 7.5kw

7. Matla a ho Seha: 3.0kw

8. Oil pump motor matla: 7.5kw

9. Lintho tse bonahalang tsa rollers: 45#tšepe, tima HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Boitsebiso ba ho itšeha lehare: Cr12Mov tšepe

12. Step of rollers: 16 steps

13. Fepa Bophara: 1000mm.

14. Effective Width: 680mm as drawing

15. Botenya ba coil: 0.6-1.6mm

16. Botebo ba groove: ho latela litšoantšo

17. boholo ba bolelele: 42 m

18. Ntlha ea ho sebetsa ea phanele: 64%