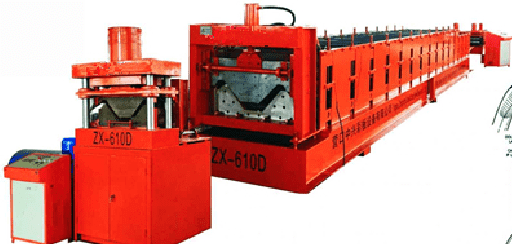

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Atụmatụ

1.1 Rollers na-eme nke ọma na-acha ọcha ígwè esichara na polishing.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Agba agbachara ga-abụ nnukwu ogologo ogologo, corrugation dị elu, ike erughị ala.

2. Main oru data nke YY-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Akụkụ akụkụ kwụ ọtọ: 10000 mm x 1400 mm x 1600 mm

Ehulata panel akụkụ size: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Mkpokọta ibu: Ihe dị ka 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Ike imepụta: 7.5kw

6. Ehulata Ike: 7.5kw

7. Ịcha ike: 3.0kw

8. Oil mgbapụta moto ike:7.5kw

9. Ihe nke rollers: 45 # ígwè, emenyụ HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Ihe eji egbutu agụba: Cr12Mov ígwè

12. Step of rollers: 16 steps

13. Obosara nri: 1000mm.

14. Effective Width: 680mm as drawing

15. Ọkpụrụkpụ nke eriri igwe: 0.6-1.6mm

16. omimi nke uzo: dika eserese

17. ogologo ogologo: 42m

18. Ihe na-arụ ọrụ nke panel: 64%