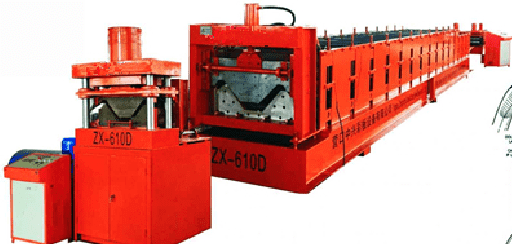

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Nta

1.1 Rollers yog ua los ntawm cov hlau dawb zoo ua tiav nrog polishing.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

1.3 Cov xim tiav lawm yuav loj heev, siab corrugation, siab nro zog.

2. Cov ntaub ntawv tseem ceeb ntawm YOG-680:

1. Punching part Size: 2900 mm x 1400 mm x 1300 mm

Qhov loj me: 10000mm x 1400mm x 1600mm

Bending vaj huam sib luag qhov loj: 1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Tag nrho qhov hnyav: Txog 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Kev tsim lub zog: 7.5kw

6. Bending zog: 7.5kw

7. Txiav fais fab: 3.0kw

8. Roj twj tso kua mis lub cev muaj zog: 7.5kw

9. Cov khoom siv ntawm cov menyuam: 45 # steel, quenched HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Cov khoom ntawm cov hniav txiav: Cr12Mov steel

12. Step of rollers: 16 steps

13. Pub Dav: 1000mm.

14. Effective Width: 680mm as drawing

15. Thickness ntawm lub kauj: 0.6-1.6mm

16. Qhov tob ntawm qhov zawj: raws li cov duab kos

17. max :42 m

18.Operating factor ntawm lub vaj huam sib luag: 64%