Basic production conditions of equipment

Equipment production conditions:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Equipment feeding direction: left in and right out.

3 Voltage parameter 380, 50Hz, 3 phases.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 Hydraulic oil: 46# hydraulic oil.

6 Gear oil: 18# hyperbolic gear oil.

Main technical parameters of the equipment

1 Rolled strip width: ≤775mm

2 Rolled strip thickness: 0.6mm/0.9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 Molding speed: 0~12m/min, online speed 0-6 M/min

6 Rolled workpiece length: user free setting

7 Total installed capacity of equipment: about 30KW.

Processing:

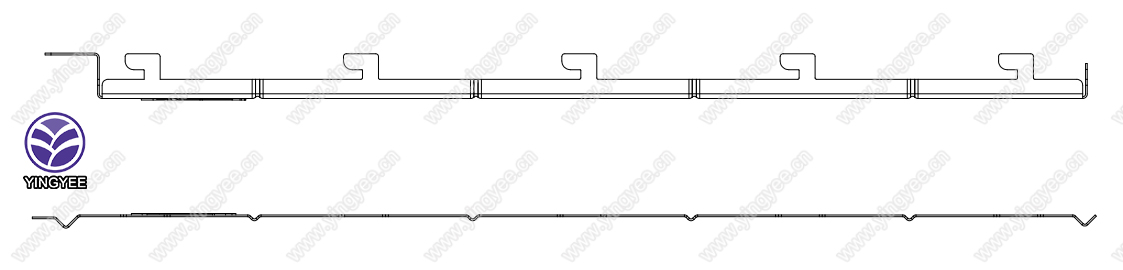

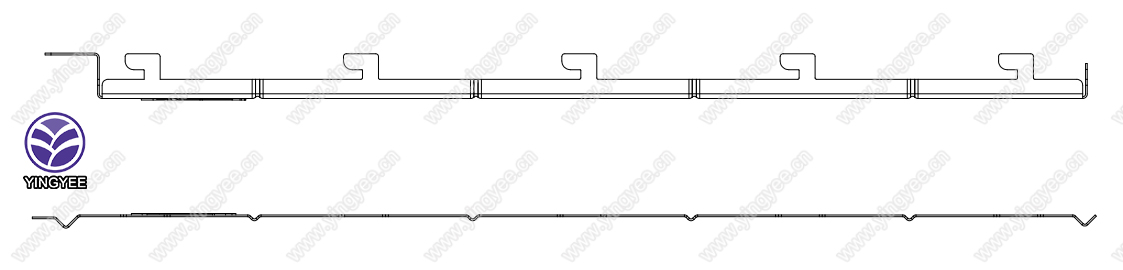

drawings:

Basic specification

|

No.

|

Items

|

Spec:

|

|

1

|

Material

|

1. Thickness: 0.6mm

2. Input width: max. 462mm

3. material: Cold rolled steel strip; yield limit σs≤260Mpa

|

|

2

|

Power supply

|

380V, 60Hz, 3 phase

|

|

3

|

Capacity of power

|

1. Total power: about 20kW

2. Punchine system power: 7.5kw

3. Roll forming machine power: 5.5kw

4. Track cutting machine power: 5kw

|

|

4

|

Speed

|

Line speed: 0-9m/min(includ punching)

Forming speed: 0-12m/min

|

|

5

|

Hydraulic oil

|

46#

|

|

6

|

Gear Oil

|

18# Hyperbolic gear oil

|

|

7

|

Dimension

|

Approx.(L*W*H) 20m×2m×2m

|

|

8

|

Stands of rollers

|

Roll forming machine for Fundo 2F: 17 rollers

One Extra roller Fundo 1F: 12 rollers

|

|

9

|

Material of rollers

|

Cr12, quenched HRC56°-60°

|

|

10

|

Length of rolled workpiece

|

User free setting

|

|

11

|

Cut style

|

Hydraulic Tracking cut

|