Kaayaan produksi dasar pakakas

Kaayaan produksi alat:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Alat arah nyoco: kénca asup jeung katuhu kaluar.

3 Parameter tegangan 380, 50Hz, 3 fase.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 minyak hidrolik: 46 # minyak hidrolik.

6 Minyak gear: 18 # minyak gear hyperbolic.

Parameter téknis utama alat

1 Rolled strip width: ≤775mm

2 Digulung ketebalan strip: 0.6mm / 0.9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 Molding speed: 0 ~ 12m / mnt, speed online 0-6 M / mnt

6 Panjang workpiece digulung: setélan bébas pamaké

7 Total kapasitas dipasang pakakas: ngeunaan 30KW.

Ngolah:

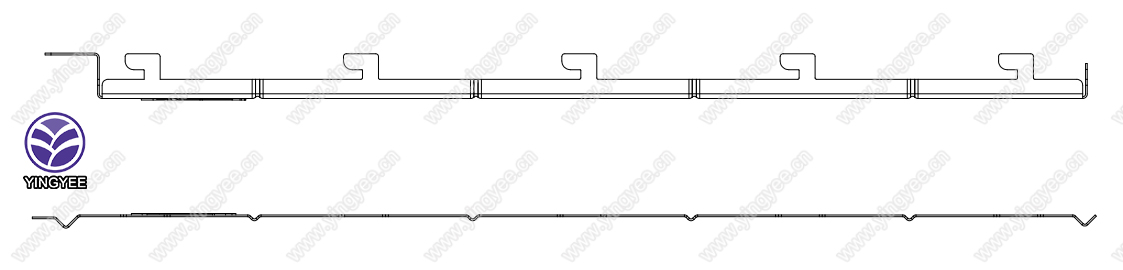

gambar:

Basic specification

|

No. |

Items |

Spec: |

|

1 |

Bahan |

1. Thickness: 0.6mm 2. Input width: max. 462mm 3. material: Cold rolled steel strip; yield limit σs≤260Mpa |

|

2 |

Power supply |

380V, 60Hz, 3 phase |

|

3 |

Capacity of power |

1. Total power: about 20kW 2. Punchine system power: 7.5kw 3. Roll forming machine power: 5.5kw 4. Track cutting machine power: 5kw |

|

4 |

Laju |

Laju garis: 0-9m / mnt (kaasup punching) Laju ngabentuk: 0-12m / mnt |

|

5 |

Minyak hidrolik |

46# |

|

6 |

Oli Gear |

18# Hyperbolic gear oil |

|

7 |

Diménsi |

Approx.(L*W*H) 20m×2m×2m |

|

8 |

Nangtung tina rollers |

Roll forming machine for Fundo 2F: 17 rollers Hiji tambahan gilinding Fundo 1F: 12 gilinding |

|

9 |

Bahan tina rollers |

Cr12, quenched HRC56°-60° |

|

10 |

Panjang workpiece digulung |

Pangaturan bébas pamaké |

|

11 |

Cut style |

Hydraulic Tracking cut |