Uskunalarni ishlab chiqarishning asosiy shartlari

Uskunani ishlab chiqarish shartlari:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Uskunani oziqlantirish yo'nalishi: chapga va o'ngga.

3 kuchlanish parametri 380, 50Hz, 3 faza.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 Shlangi moy: 46 # gidravlik moy.

6 tishli moy: 18 # giperbolik tishli moy.

Uskunaning asosiy texnik parametrlari

1 Rolled strip width: ≤775mm

2 Rolled Ip qalinligi: 0,6mm/0,9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 Kalıplama tezligi: 0 ~ 12m / min, onlayn tezlik 0-6 M / min

6 O'ralgan ishlov beriladigan qismning uzunligi: foydalanuvchi uchun bepul sozlash

7 Uskunaning umumiy o'rnatilgan quvvati: taxminan 30KVt.

Qayta ishlash:

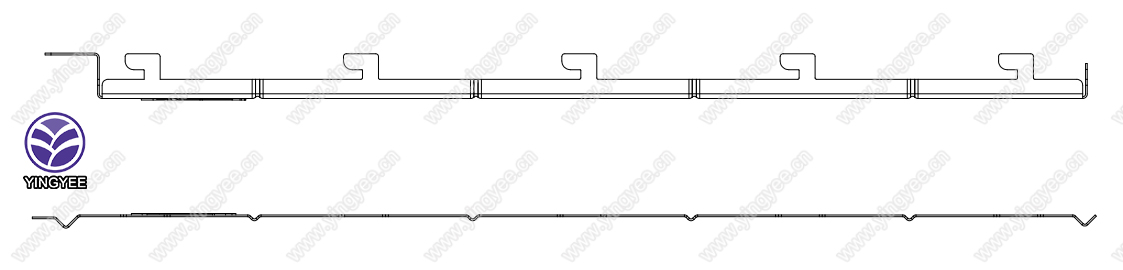

chizmalar:

Basic specification

|

No. |

Items |

Spec: |

|

1 |

Material |

1. Thickness: 0.6mm 2. Input width: max. 462mm 3. material: Cold rolled steel strip; yield limit σs≤260Mpa |

|

2 |

Power supply |

380V, 60Hz, 3 phase |

|

3 |

Capacity of power |

1. Total power: about 20kW 2. Punchine system power: 7.5kw 3. Roll forming machine power: 5.5kw 4. Track cutting machine power: 5kw |

|

4 |

Tezlik |

Chiziq tezligi: 0-9 m/min (zarb bilan teshish) Shakllanish tezligi: 0-12m/min |

|

5 |

Gidravlik moy |

46# |

|

6 |

Tishli moy |

18# Hyperbolic gear oil |

|

7 |

Hajmi |

Approx.(L*W*H) 20m×2m×2m |

|

8 |

Roliklarning stendlari |

Roll forming machine for Fundo 2F: 17 rollers Fundo 1F bitta qo'shimcha rolik: 12 rolik |

|

9 |

Roliklarning materiali |

Cr12, quenched HRC56°-60° |

|

10 |

Yuklangan ish qismining uzunligi |

Foydalanuvchi uchun bepul sozlama |

|

11 |

Cut style |

Hydraulic Tracking cut |