Awọn ipo iṣelọpọ ipilẹ ti ẹrọ

Awọn ipo iṣelọpọ ohun elo:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Itọsọna ifunni ohun elo: osi sinu ati ọtun jade.

3 Foliteji paramita 380, 50Hz, 3 awọn ipele.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 Epo eefun: 46# epo hydraulic.

6 Epo jia: 18 # epo jia hyperbolic.

Awọn ifilelẹ imọ-ẹrọ akọkọ ti ẹrọ

1 Rolled strip width: ≤775mm

2 Yiyi rinhoho sisanra: 0.6mm / 0.9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 Iyara mimu: 0 ~ 12m / min, iyara ori ayelujara 0-6 M / min

6 Yiyi workpiece ipari: olumulo free eto

7 Lapapọ agbara fi sori ẹrọ ti ẹrọ: nipa 30KW.

Ṣiṣẹ:

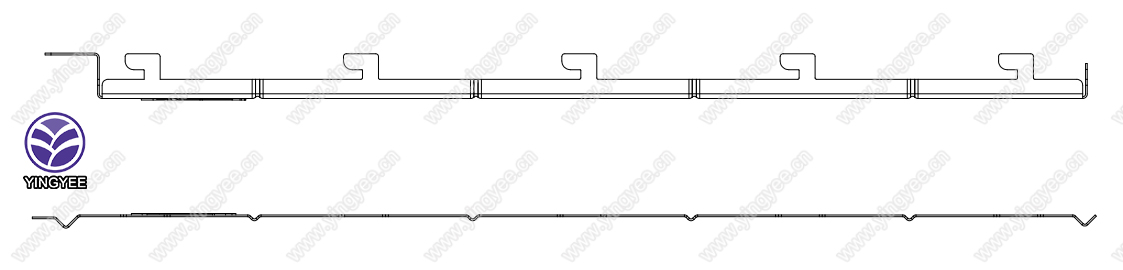

awọn aworan:

Basic specification

|

No. |

Items |

Spec: |

|

1 |

Ohun elo |

1. Thickness: 0.6mm 2. Input width: max. 462mm 3. material: Cold rolled steel strip; yield limit σs≤260Mpa |

|

2 |

Power supply |

380V, 60Hz, 3 phase |

|

3 |

Capacity of power |

1. Total power: about 20kW 2. Punchine system power: 7.5kw 3. Roll forming machine power: 5.5kw 4. Track cutting machine power: 5kw |

|

4 |

Iyara |

Iyara ila: 0-9m/min (pẹlu punching) Iyara dagba: 0-12m / min |

|

5 |

Epo hydraulic |

46# |

|

6 |

Jia Epo |

18# Hyperbolic gear oil |

|

7 |

Iwọn |

Approx.(L*W*H) 20m×2m×2m |

|

8 |

Awọn iduro ti rollers |

Roll forming machine for Fundo 2F: 17 rollers Ọkan Afikun rola Fundo 1F: 12 rollers |

|

9 |

Ohun elo ti rollers |

Cr12, quenched HRC56°-60° |

|

10 |

Gigun ti yiyi workpiece |

Eto ọfẹ olumulo |

|

11 |

Cut style |

Hydraulic Tracking cut |