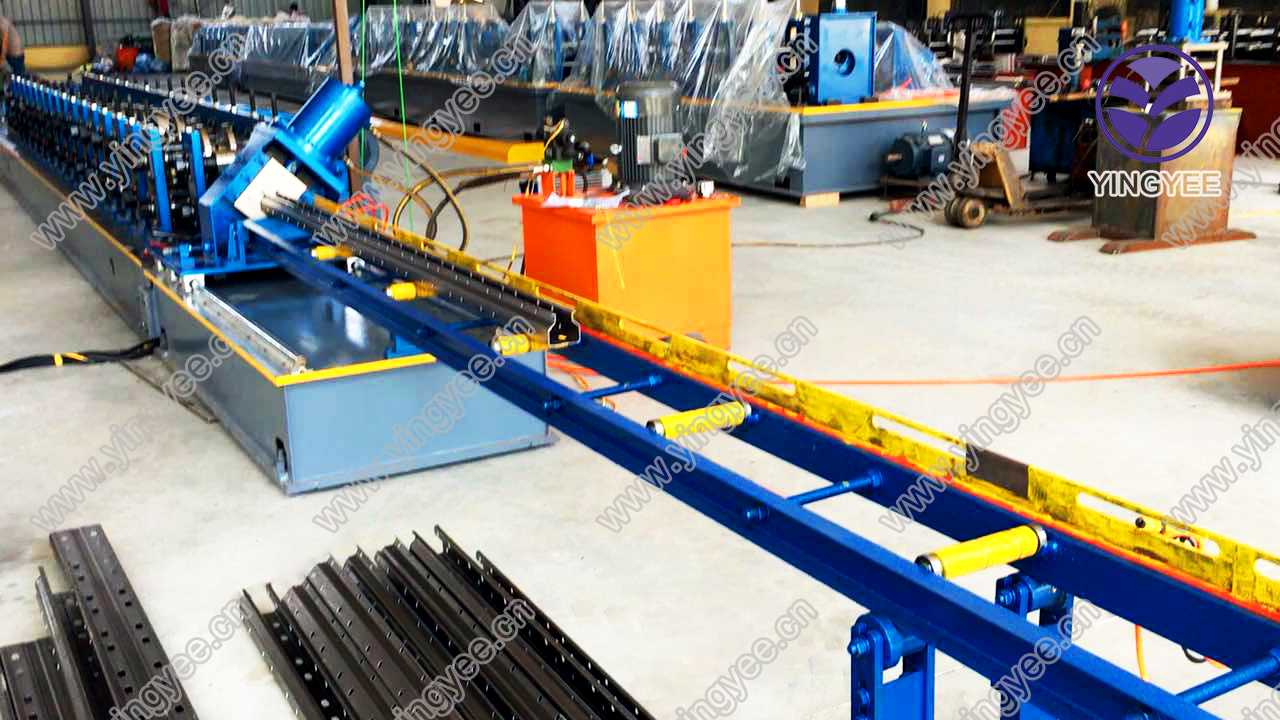

Ang storage rack forming machine ay isang full-automatic na linya ng produksyon, na maaaring gumawa ng mabigat na rack na may maximum na kapal na 3mm.

Mga proseso at bahagi ng linya ng produksyon

3T hydraulic de-coiler with leveling*1

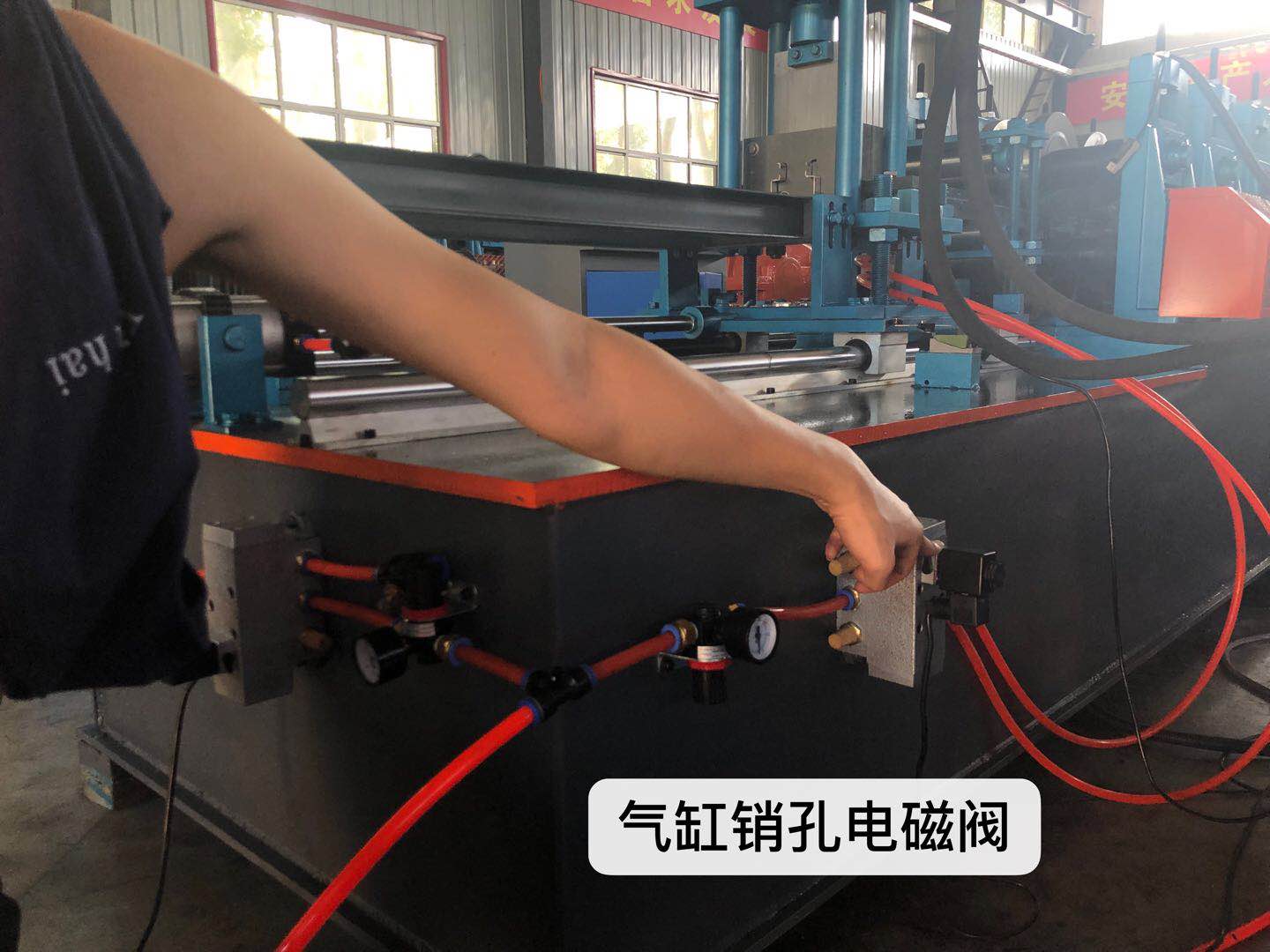

40Tons punching machine with servo feeder (With 2 sets punching molds) *1

Main roll forming machine *1

Hydraulic cutting system *1

Hydraulic station *1

PLC Control system *1

Ang roller material ay Cr12 ay may mas mataas na kalidad at mas mahabang buhay ng serbisyo.

|

Lugar ng sahig ng kagamitan |

Approx 20 * 1.7 *1.5 meters |

|

Mga materyales |

GI strips |

|

Bilis |

12m/min |

|

Bumubuo ng mga hakbang ng roller |

12 roller steps |

|

tatak ng pagsuntok |

YangLi mechanical power punching machine |

|

Kabuuang kapangyarihan |

18.5kw |

|

Parameter ng boltahe |

380V, 50Hz, 3 phase or as customers required |

|

Kabuuang timbang |

Approx 10tons |

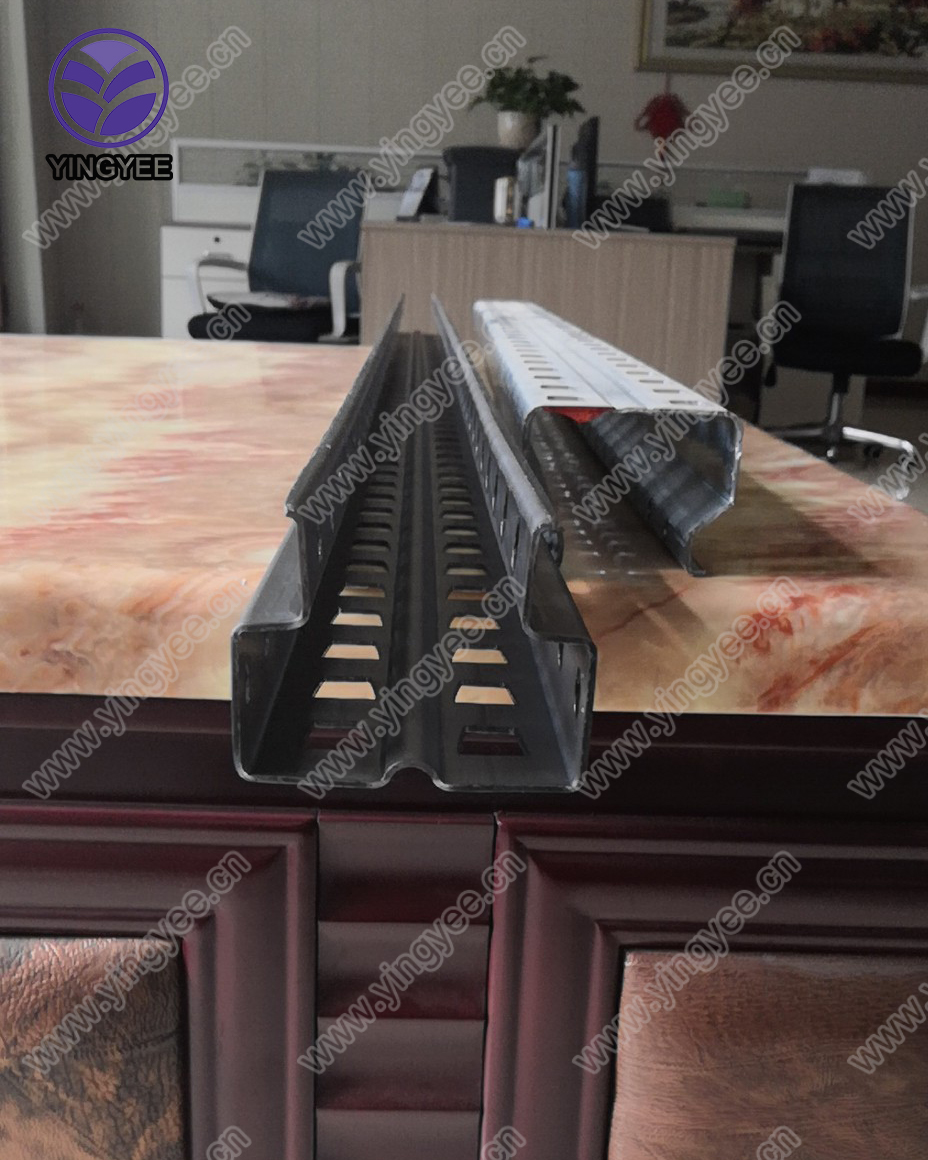

Storage rack roll forming machine with good forming and punching effect. The storage rack forming machine is a full-automatic production line, which can do heavy rack with a maximum thickness of 3mm.

The whole production line has high production efficiency and comprehensive speed of 8-10m/min.

Ang roller material ay Cr12 ay may mas mataas na kalidad at mas mahabang buhay ng serbisyo.

For this production line, we supply PLC adjust guide and video, Circuit diagrams,supply sample for confirm. And we have experienced engineers know how to deal with installation and other issues.

And here are the configutarions:

Processes and components

3T hydraulic de-coiler na may leveling*1

40Tons punching machine na may servo feeder (May 2 set na punching molds) *1

Pangunahing roll forming machine *1

Hydraulic cutting system *1

Istasyon ng haydroliko *1

PLC Control system *1