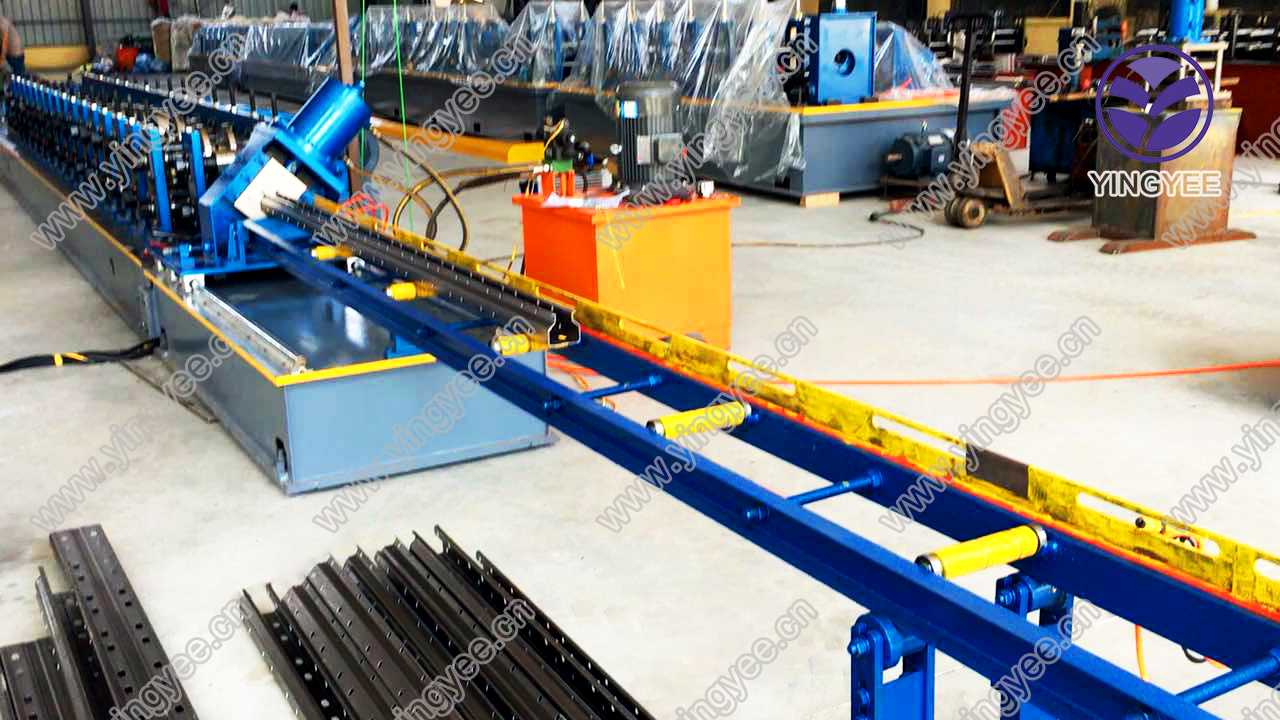

生產線流程及組成

3T hydraulic de-coiler with leveling*1

40Tons punching machine with servo feeder (With 2 sets punching molds) *1

Main roll forming machine *1

Hydraulic cutting system *1

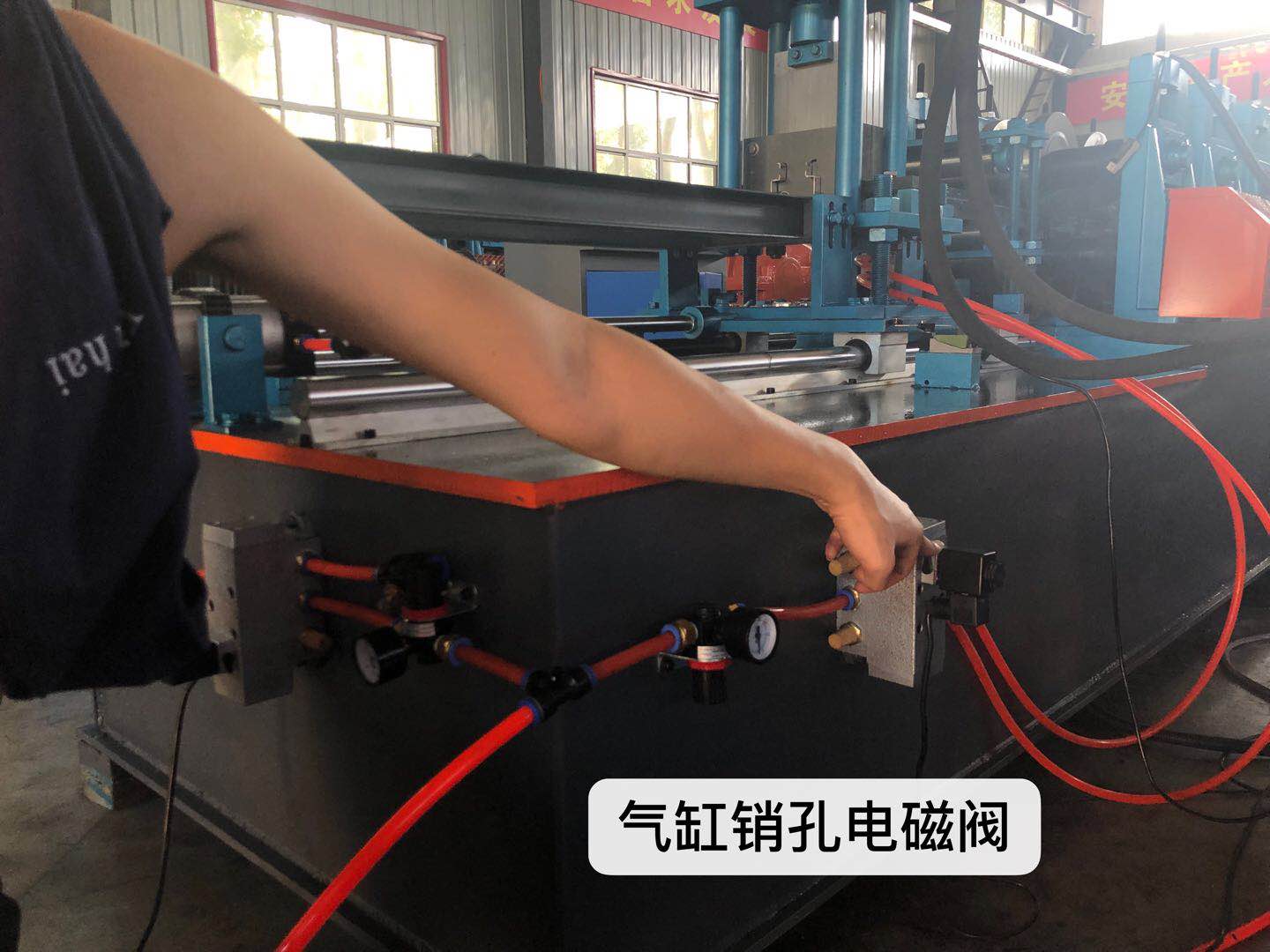

Hydraulic station *1

PLC Control system *1

滾輪材質為Cr12,品質更高,使用壽命更長。

|

設備佔地面積 |

Approx 20 * 1.7 *1.5 meters |

|

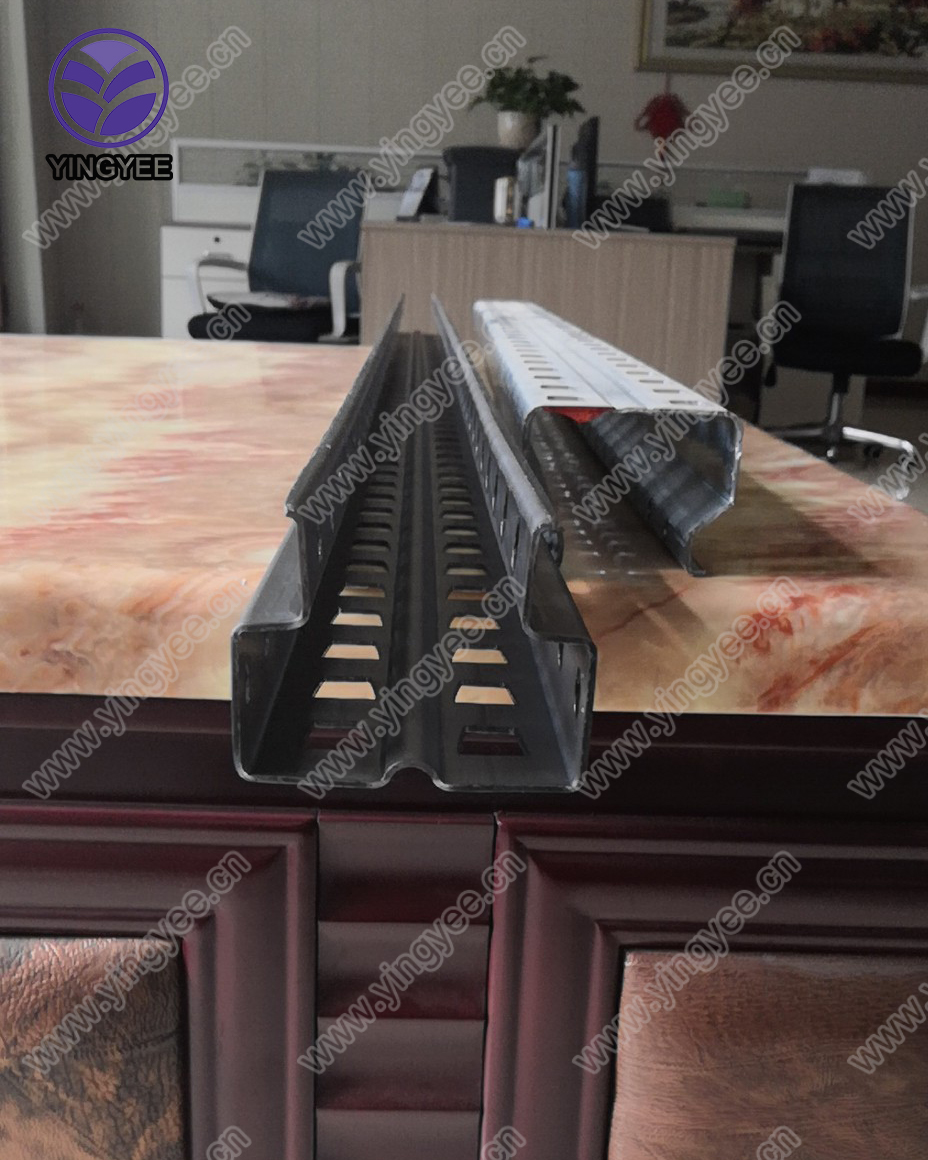

材料 |

胃腸道條帶 |

|

速度 |

12m/分鐘 |

|

成型輥台階 |

12 個滾輪台階 |

|

沖孔品牌 |

揚力機械動力沖孔機 |

|

總功率 |

18.5千瓦 |

|

電壓參數 |

380V, 50Hz, 3 phase or as customers required |

|

總重量 |

Approx 10tons |

The whole production line has high production efficiency and comprehensive speed of 8-10m/min.

滾輪材質為Cr12,品質更高,使用壽命更長。

For this production line, we supply PLC adjust guide and video, Circuit diagrams,supply sample for confirm. And we have experienced engineers know how to deal with installation and other issues.

And here are the configutarions:

流程和組件

3T液壓調平開捲機*1

40噸伺服送料沖床(附2套沖孔模具)*1

主成型機*1

液壓切割系統*1

液壓站*1

PLC控制系統*1