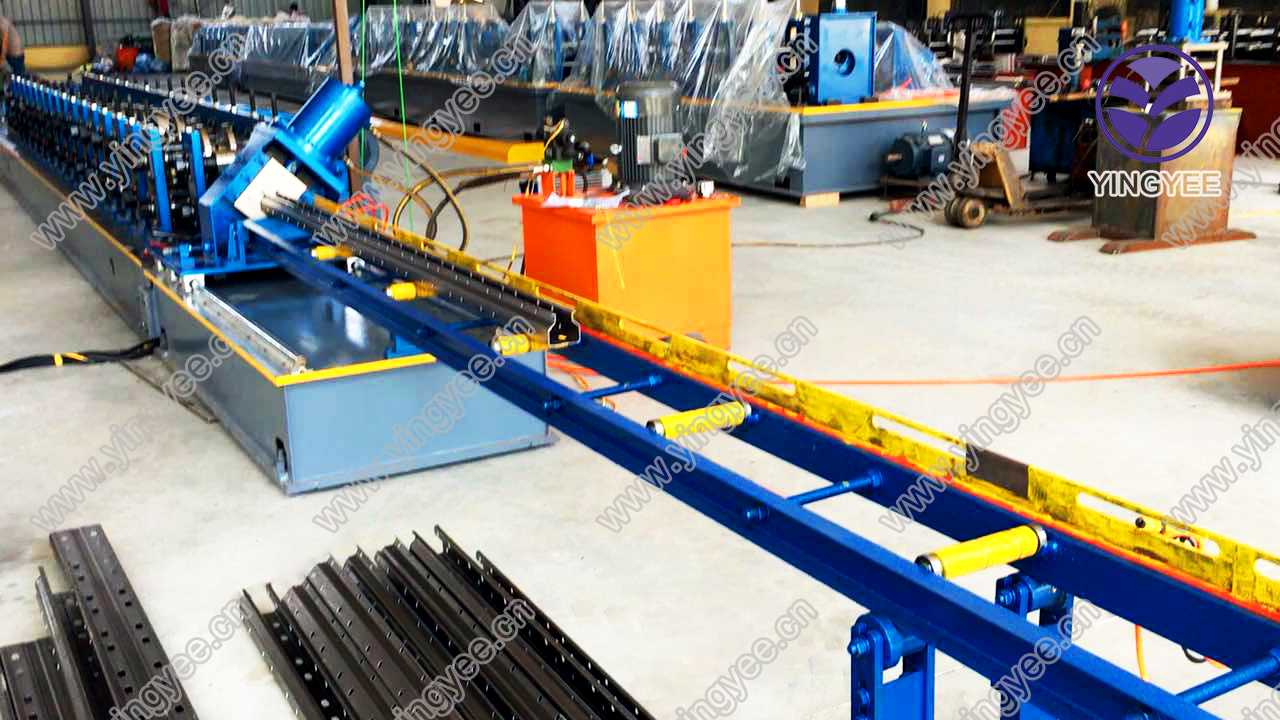

Saqlash rafini shakllantirish mashinasi to'liq avtomatik ishlab chiqarish liniyasi bo'lib, maksimal qalinligi 3 mm bo'lgan og'ir raftlarni bajarishi mumkin.

Ishlab chiqarish liniyasining jarayonlari va tarkibiy qismlari

Nivelirli 3T gidravlik de-koiler*1

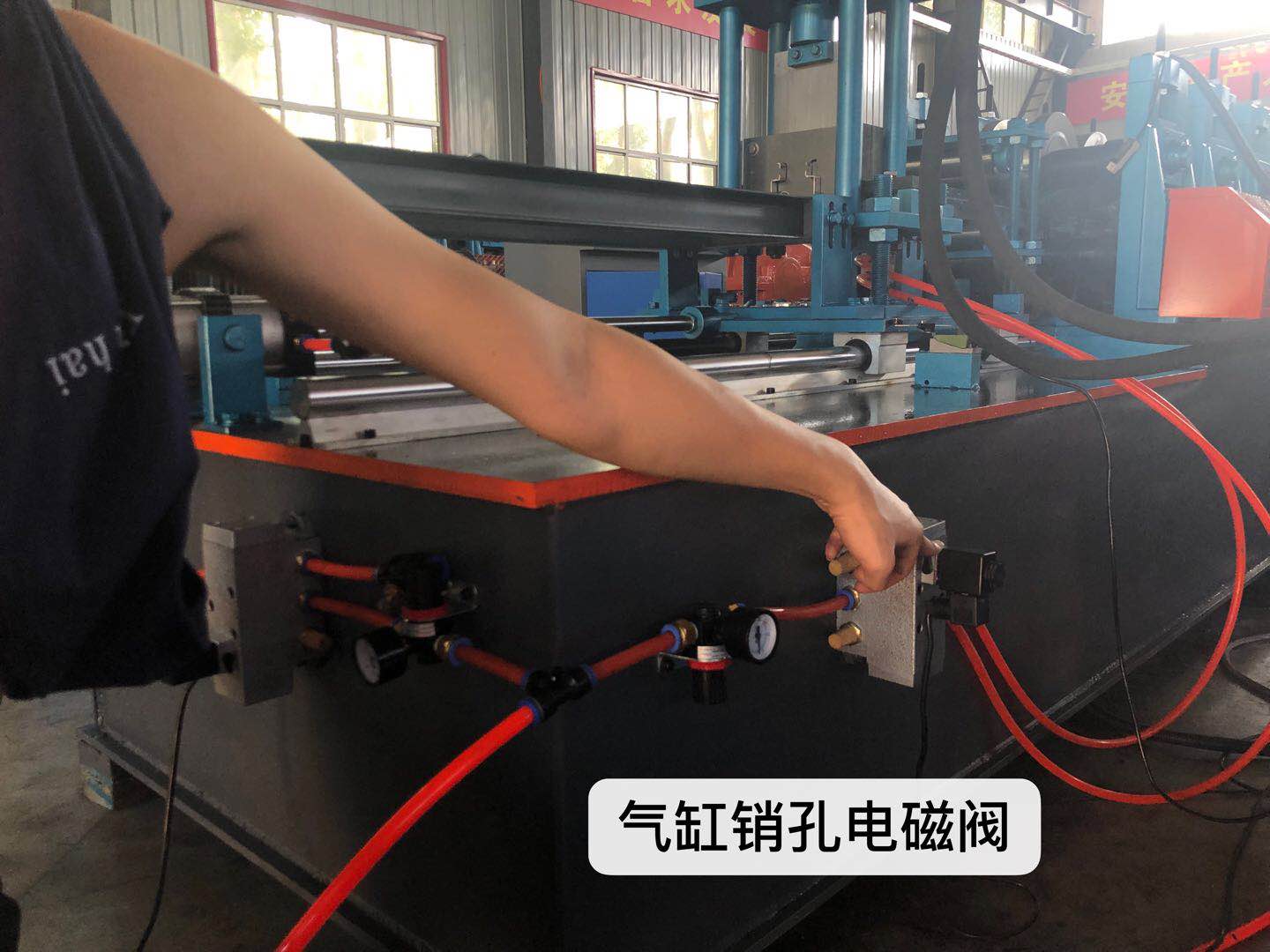

Servo oziqlantiruvchi bilan 40 tonna zımba mashinasi (2 to'plam zımbalama qoliplari bilan) * 1

Asosiy rulonni shakllantirish mashinasi * 1

Gidravlik kesish tizimi *1

Gidravlika stantsiyasi * 1

PLC boshqaruv tizimi *1

Rolikli material Cr12 yuqori sifatli va uzoqroq xizmat muddatiga ega.

|

Uskunaning zamin maydoni |

Taxminan 20 * 1,7 * 1,5 metr |

|

Materiallar |

GI chiziqlar |

|

Tezlik |

12m/min |

|

Rolikli qadamlarni shakllantirish |

12 rulonli qadam |

|

Punching brendi |

YangLi mexanik quvvat zımbalama mashinasi |

|

Umumiy quvvat |

18,5 kVt |

|

Voltaj parametri |

380V, 50Hz, 3 fazali yoki mijozlar talabiga binoan |

|

Umumiy og'irlik |

Taxminan 10 tonna |

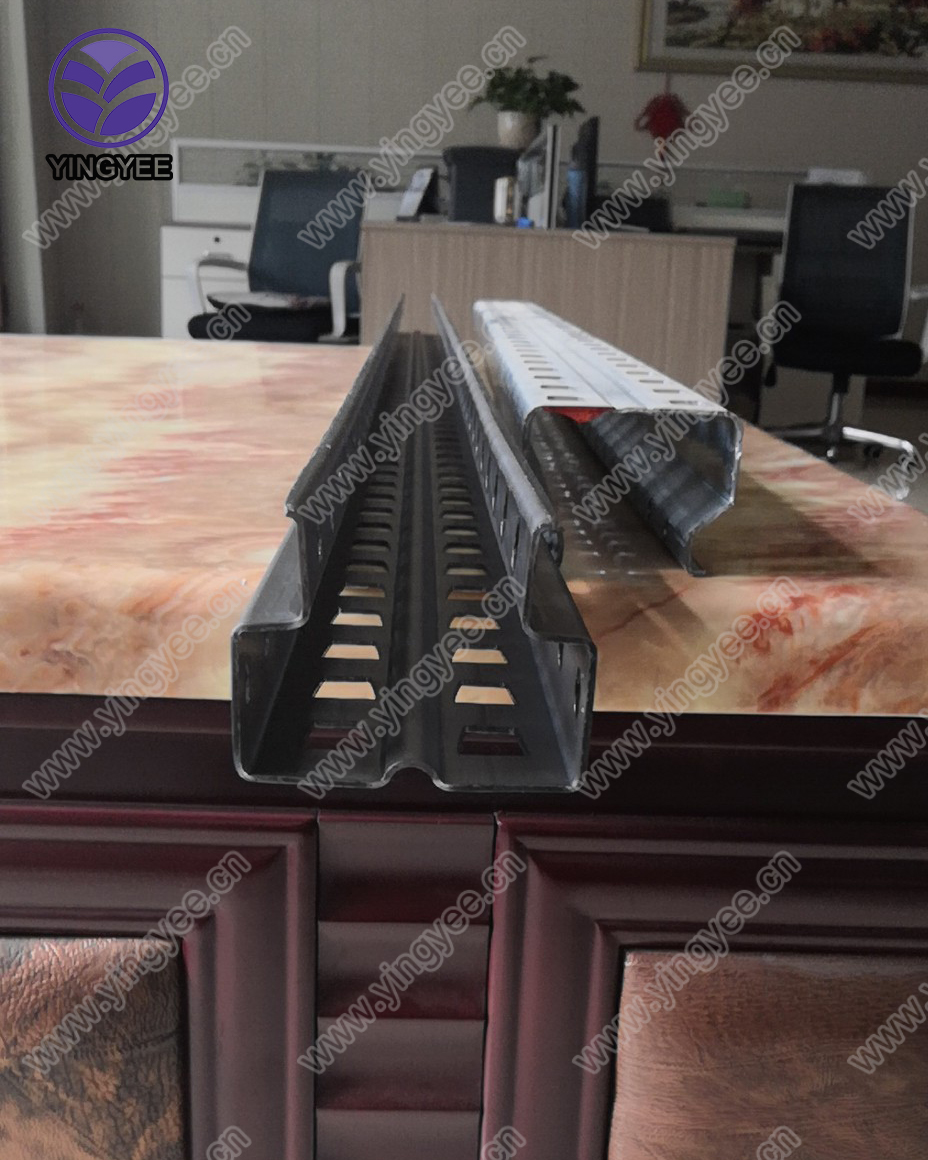

Storage rack roll forming machine with good forming and punching effect. The storage rack forming machine is a full-automatic production line, which can do heavy rack with a maximum thickness of 3mm.

The whole production line has high production efficiency and comprehensive speed of 8-10m/min.

Rolikli material Cr12 yuqori sifatli va uzoqroq xizmat muddatiga ega.

For this production line, we supply PLC adjust guide and video, Circuit diagrams,supply sample for confirm. And we have experienced engineers know how to deal with installation and other issues.

And here are the configutarions:

Processes and components

Nivelirli 3T gidravlik de-koiler*1

Servo oziqlantiruvchi bilan 40 tonna zımba mashinasi (2 to'plam zımbalama qoliplari bilan) * 1

Asosiy rulonni shakllantirish mashinasi * 1

Gidravlik kesish tizimi *1

Gidravlika stantsiyasi * 1

PLC boshqaruv tizimi *1