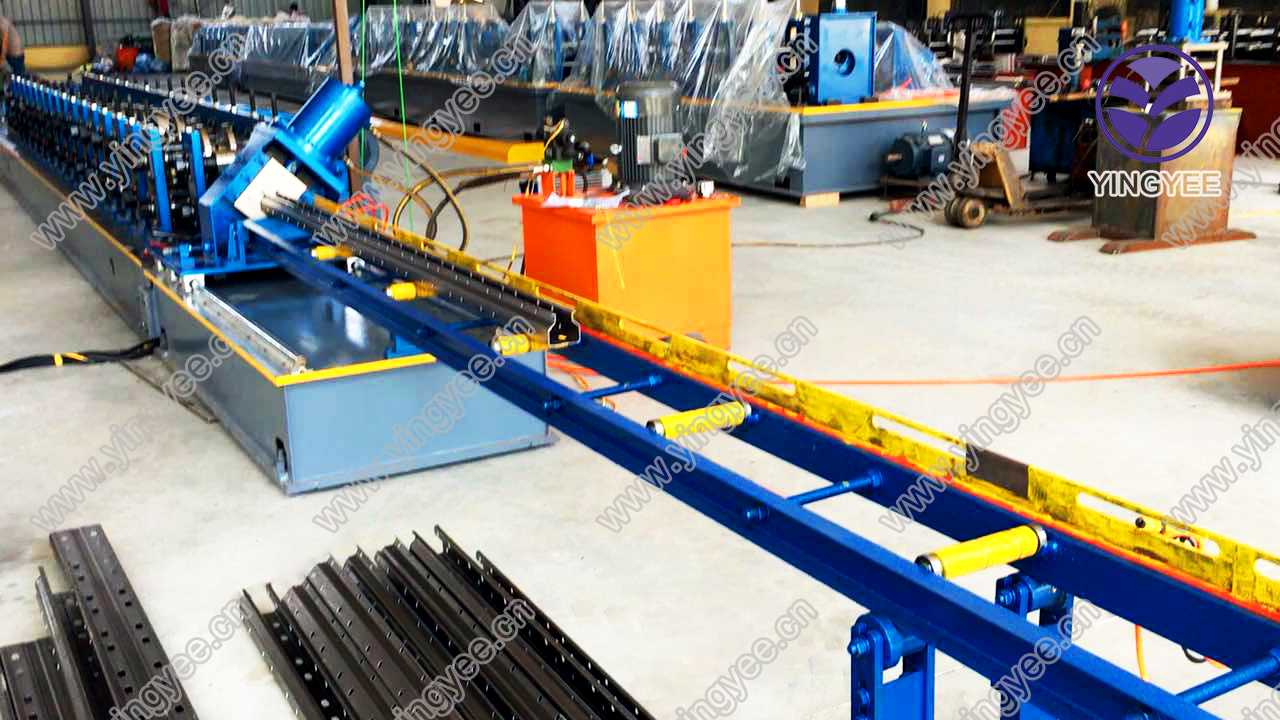

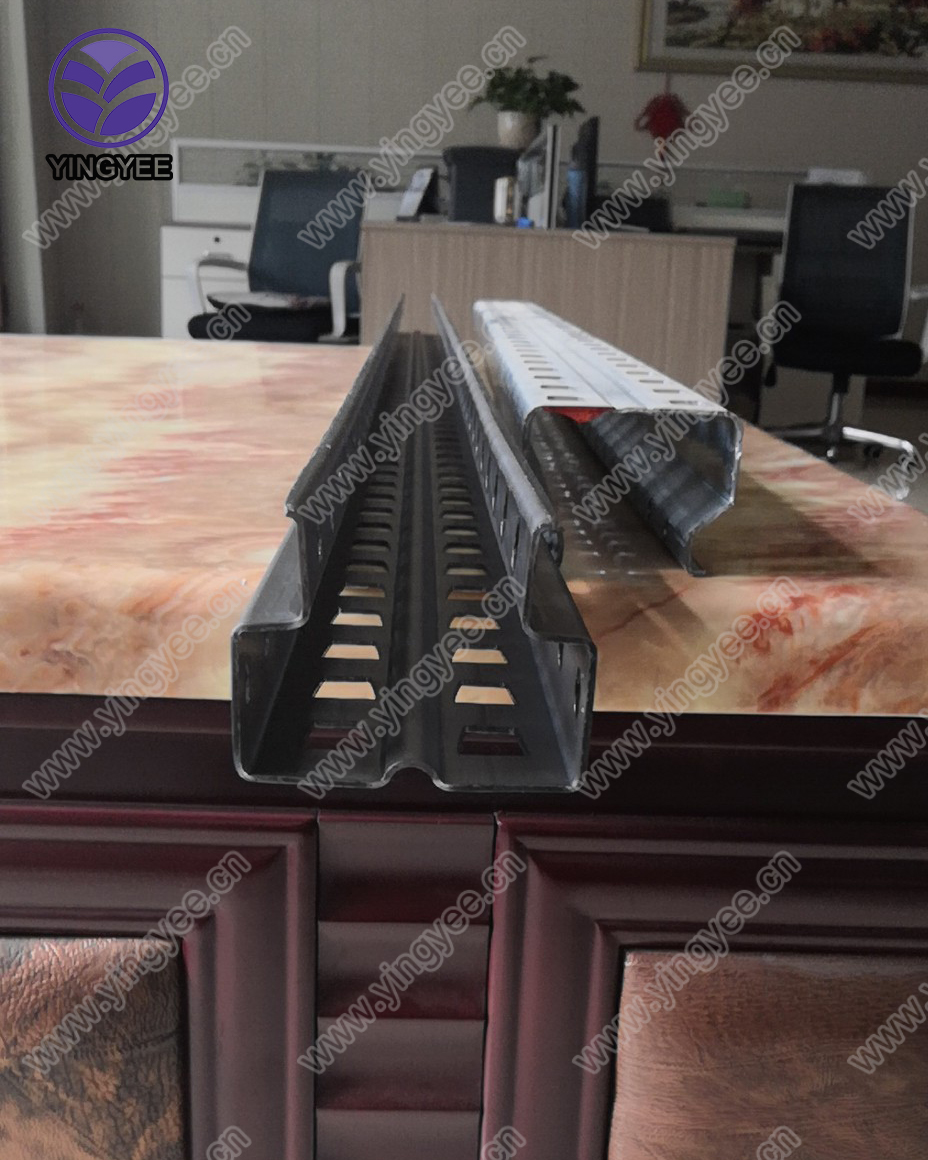

Mashine ya kutengeneza rack ya kuhifadhi ni mstari wa uzalishaji wa moja kwa moja, ambao unaweza kufanya rack nzito na unene wa juu wa 3mm.

Michakato na vipengele vya mstari wa uzalishaji

3T hydraulic de-coiler with leveling*1

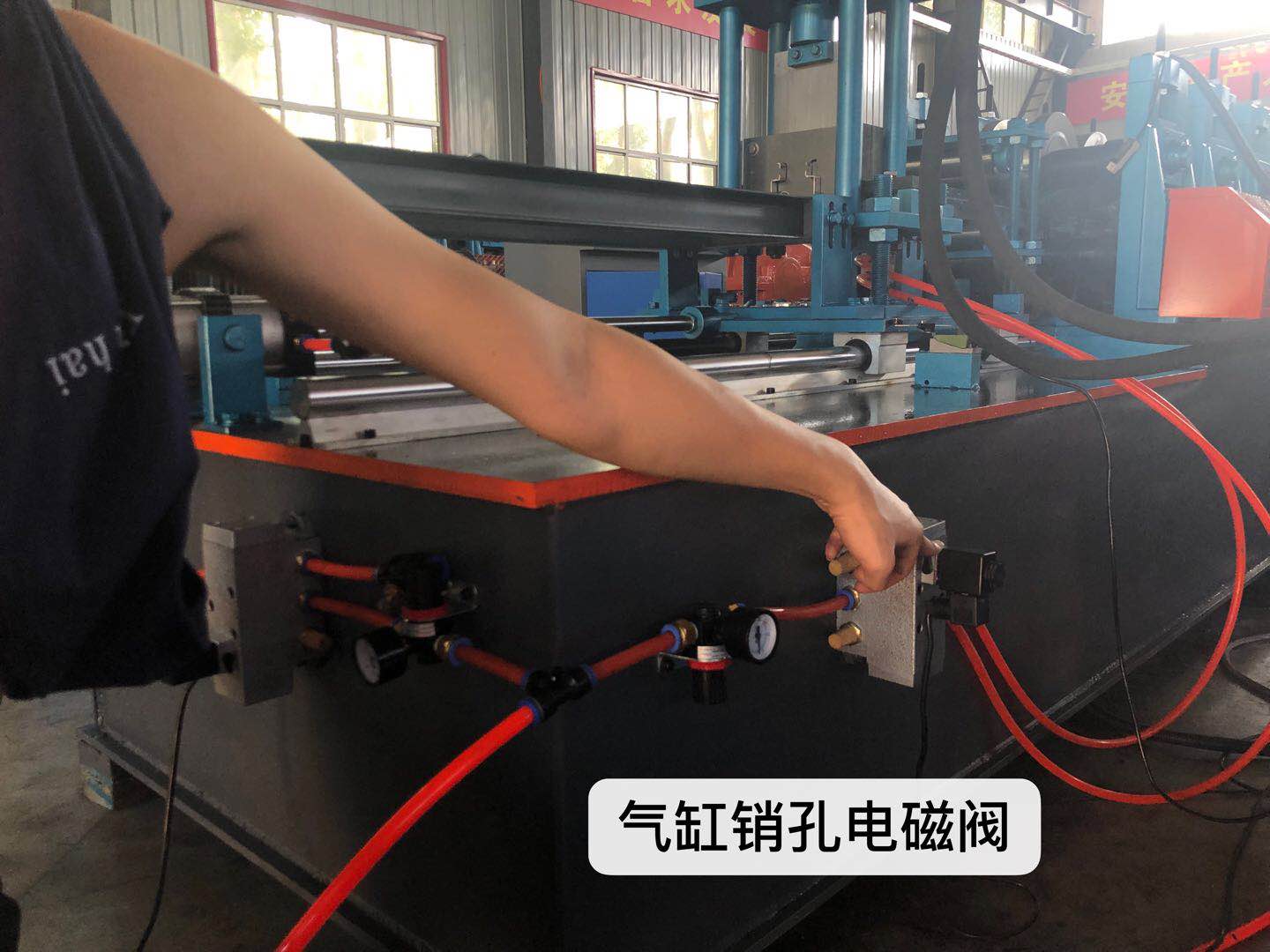

40Tons punching machine with servo feeder (With 2 sets punching molds) *1

Main roll forming machine *1

Hydraulic cutting system *1

Hydraulic station *1

PLC Control system *1

Nyenzo ya roller ni Cr12 ina ubora wa juu na maisha marefu ya huduma.

|

Sehemu ya sakafu ya vifaa |

Approx 20 * 1.7 *1.5 meters |

|

Nyenzo |

Vipande vya GI |

|

Kasi |

12m/dak |

|

Kuunda hatua za roller |

Hatua 12 za roller |

|

Kupiga chapa |

YangLi mitambo nguvu kuchomwa mashine |

|

Jumla ya nguvu |

18.5kw |

|

Kigezo cha voltage |

380V, 50Hz, 3 phase or as customers required |

|

Uzito wote |

Approx 10tons |

Storage rack roll forming machine with good forming and punching effect. The storage rack forming machine is a full-automatic production line, which can do heavy rack with a maximum thickness of 3mm.

The whole production line has high production efficiency and comprehensive speed of 8-10m/min.

Nyenzo ya roller ni Cr12 ina ubora wa juu na maisha marefu ya huduma.

For this production line, we supply PLC adjust guide and video, Circuit diagrams,supply sample for confirm. And we have experienced engineers know how to deal with installation and other issues.

And here are the configutarions:

Processes and components

3T hydraulic de-coiler yenye kusawazisha*1

Mashine ya kutoboa tani 40 yenye feeder ya servo (yenye viunzi 2 vya kuchomwa) *1

Mashine kuu ya kutengeneza roll *1

Mfumo wa kukata hydraulic *1

Kituo cha majimaji *1

Mfumo wa Udhibiti wa PLC *1