The Evolution and Importance of Wall Angle Making Machines in Drywall Construction

In the realm of contemporary construction, particularly in drywall installation, the need for efficiency, precision, and quality has become paramount. Among various tools designed to enhance these aspects, the wall angle making machine stands out. Specifically designed for creating C channels and main channels, these machines offer significant advancements over traditional manual methods.

The Role of Wall Angle Making Machines

Wall angle making machines are specialized equipment used to manufacture precise angles and profiles for drywall frameworks. Traditionally, constructing these angles required extensive manual labor and craftsmanship, making the process labor-intensive and prone to human error. With the introduction of automated technology, wall angle making machines have revolutionized this aspect of construction.

These machines not only significantly speed up the production process but also ensure a higher level of accuracy. By automating the dimensions and angles, they minimize the discrepancies that often occur with manual cuts. This precision is crucial in maintaining the structural integrity and aesthetic appeal of the drywall installation.

Features of Modern Wall Angle Making Machines

Modern wall angle making machines come equipped with advanced features that facilitate their operation. Most machines are designed to handle a variety of materials, including steel and aluminum, allowing for versatility in construction projects. They utilize computerized controls that allow for easy adjustments and programming, enabling operators to quickly switch between different profiles and angles as required.

Additionally, these machines incorporate safety features that protect operators from potential hazards. With automatic feeding systems and built-in safety sensors, they reduce the likelihood of accidents, promoting a safer working environment. As the construction industry continues to prioritize worker safety, these advancements offer an essential improvement.

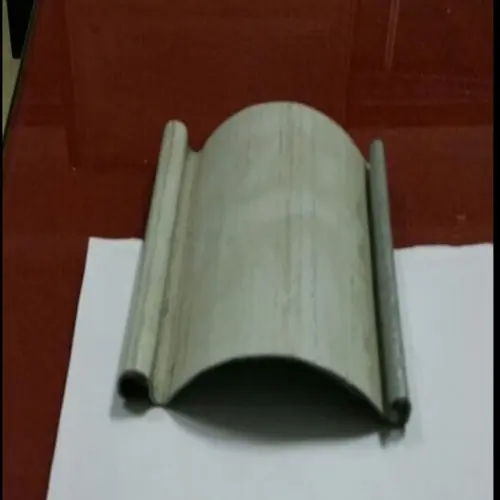

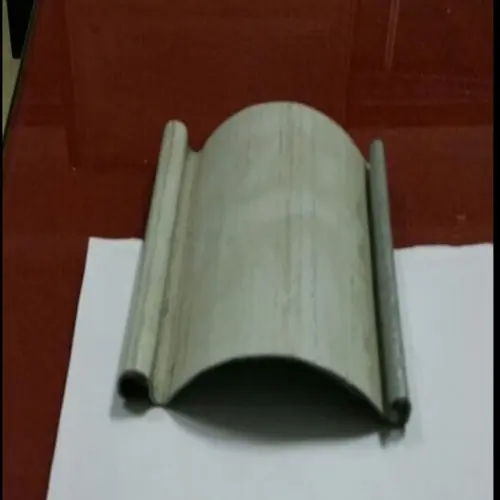

automatic stud and track/drywall/c channel/main channel/wall angle making machine

Economic Benefits

Investing in a wall angle making machine provides significant economic benefits for construction companies. The efficiency gained through automation translates to time savings, allowing projects to be completed faster and with fewer labor hours. This can lead to a reduction in overall project costs, which is a compelling advantage in a competitive market.

Moreover, the precision of the wall angle making machines reduces material waste. With accurate cuts, there is less scrap material generated from errors, leading to cost savings in materials. As sustainability becomes increasingly critical in construction, these factors contribute to more environmentally friendly practices.

Future Trends

As technology continues to progress, the future of wall angle making machines is likely to see further innovations. Integration with Building Information Modeling (BIM) and other digital construction methodologies could enhance their functionality, allowing for even more precise specifications based on project requirements. Additionally, advancements in automation and robotics may lead to fully automated systems that can operate with minimal human intervention.

Conclusion

The wall angle making machine embodies the intersection of technology and construction, providing a vital tool for drywall installers. Its introduction has transformed the way angles and channels are produced, emphasizing efficiency, accuracy, and safety. As the industry evolves, these machines will undoubtedly play an integral role in meeting the demands of modern construction, making them indispensable in any drywall-centric project. Investing in a wall angle making machine not only positions companies for success in a fast-paced market but also paves the way for future innovations in the construction field.