Cable Tray Making Machine Revolutionizing Cable Management Solutions

In today’s rapidly advancing technological landscape, effective cable management has become crucial for various industries, including telecommunications, construction, and manufacturing. Among the innovations that have emerged to address this need is the cable tray making machine, a sophisticated piece of equipment designed to produce cable trays with efficiency and precision. These machines have not only streamlined the manufacturing process but have also significantly improved the quality and durability of the end products.

Cable trays are essential components in electrical and electronic systems, providing support and protection for cables and wiring. They play a pivotal role in maintaining organized and efficient installations, reducing hazards, and ensuring easy access for maintenance and upgrades. The demand for cable trays has surged alongside the growth of the electrical and telecommunications sectors, prompting manufacturers to seek out advanced machinery to meet these needs.

The Functionality of Cable Tray Making Machines

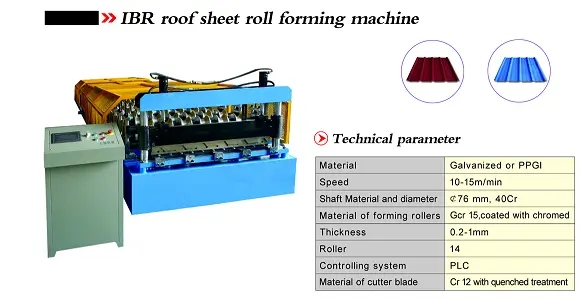

A cable tray making machine typically consists of various components, including a roll-forming system, cutting tools, and sometimes punching machinery, all integrated into a single streamlined unit. The roll-forming process involves feeding flat metal sheets or strips into the machine, which then bends and shapes them into the desired tray profile. This process can be customized to create different sizes and designs of trays, ensuring that manufacturers can produce products tailored to specific applications.

One of the key advantages of employing a cable tray making machine is the efficiency it introduces to the manufacturing process. Traditional methods of producing cable trays often involve manual labor, which can be time-consuming and prone to errors. In contrast, modern machines automate most of the production stages, significantly reducing labor costs and production time. This efficiency also translates into higher output, allowing manufacturers to meet large orders and tight deadlines more effectively.

Quality and Precision

Beyond efficiency, cable tray making machines are designed to uphold high standards of quality and precision. The advanced technology used in these machines ensures that every tray produced meets stringent specifications regarding dimensions, strength, and finish. For instance, automated cutting and welding systems can minimize the risk of human error, resulting in uniformity across batches and enhancing the overall reliability of the trays.

Moreover, many cable tray making machines are capable of working with a variety of materials, including galvanized steel, stainless steel, and aluminum. This versatility allows manufacturers to offer diverse products that can cater to different environmental conditions and customer preferences. High-quality materials combined with precision manufacturing result in cable trays that can withstand heavy loads, corrosion, and other environmental factors.

Economic and Environmental Considerations

Investing in a cable tray making machine is not just a smart choice for productivity but also for sustainability. By streamlining the production process, manufacturers can reduce material waste and energy consumption. Many modern machines are designed with energy efficiency in mind, contributing to a lower carbon footprint throughout the manufacturing cycle.

Furthermore, as industries increasingly focus on sustainability, the ability to produce cable trays from recyclable materials can be a significant selling point, attracting environmentally-conscious customers seeking sustainable solutions.

Conclusion

In summary, cable tray making machines have revolutionized the way manufacturers approach cable management solutions. By enhancing efficiency, precision, and sustainability, these machines not only help meet the growing demand for high-quality cable trays but also empower manufacturers to stay competitive in an ever-evolving marketplace. As industries continue to expand and innovate, the importance of reliable and effective cable management systems will only intensify, making cable tray making machines an indispensable asset for modern production facilities.