The Ridge Cap Machine Innovation in Fabrication

In today’s manufacturing landscape, efficiency and precision are paramount. Among the tools that have gained traction, the ridge cap machine stands out as a vital innovation in the production of roofing materials. This specialized machine is designed to create ridge caps, which are essential components in roofing systems, ensuring durability and aesthetics. This article explores the significance, functionality, and advantages of ridge cap machines within the roofing industry.

Understanding Ridge Caps

Ridge caps serve as the finishing touch in roofing construction, providing a critical seal at the peak of the roof where two slopes meet. They not only add visual appeal but also play a significant role in waterproofing and weather resistance. A well-constructed ridge cap prevents water infiltration and helps preserve the integrity of the roofing structure. Given their importance, the need for precision in their fabrication is indispensable.

The Functionality of Ridge Cap Machines

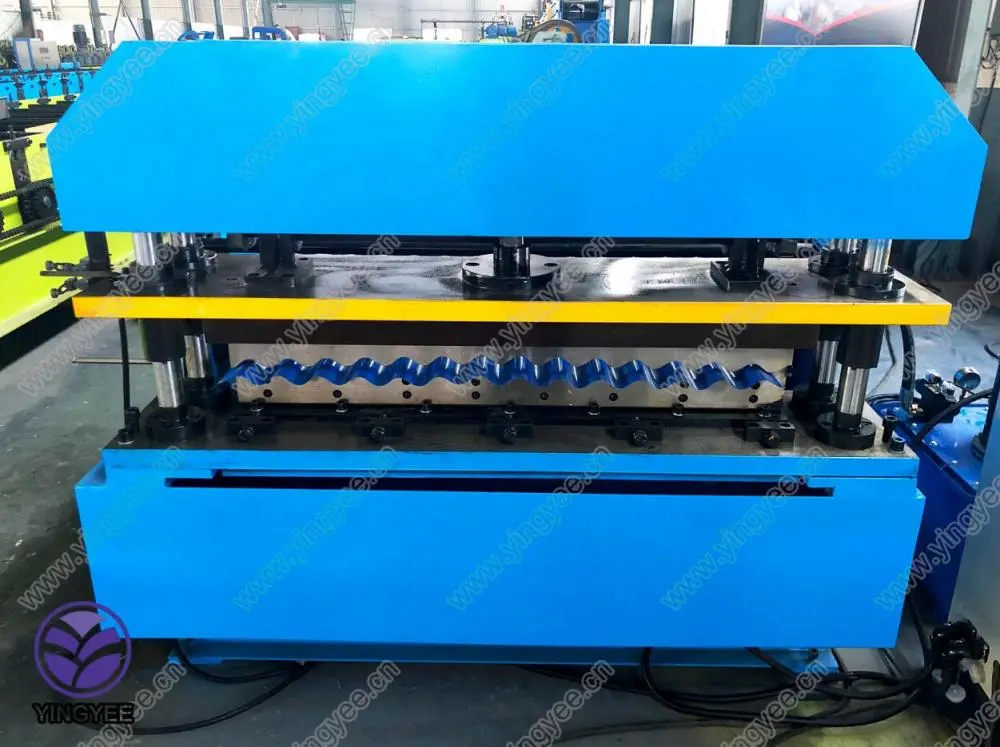

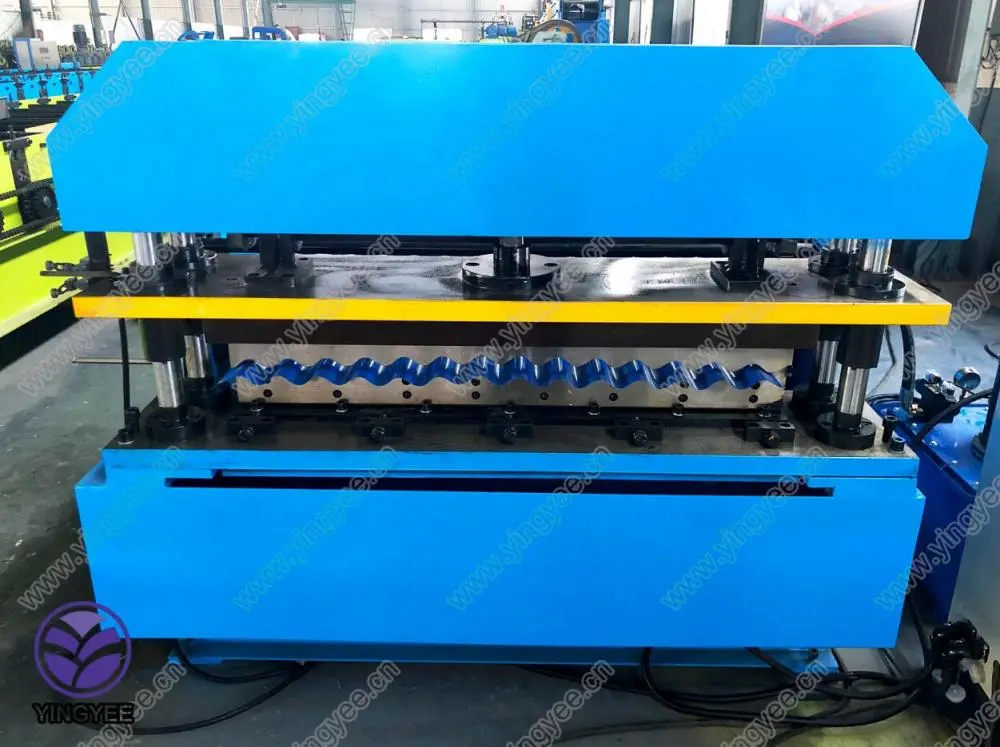

Ridge cap machines are designed to automate the production process of these vital roofing components. They utilize advanced technology to transform raw materials, typically metal sheets, into accurately shaped ridge caps. The operation begins with the loading of flat metal sheets into the machine, where they are then processed through various stages, including cutting, bending, and forming.

The most advanced machines integrate computerized controls, allowing for precise measurements and adjustments. Operators can input specific dimensions and material types, ensuring that each ridge cap produced meets the required specifications. This level of automation not only speeds up production but reduces human error, leading to a higher quality product.

Advantages of Using Ridge Cap Machines

ridge cap machine

1. Efficiency and Speed Traditional methods of producing ridge caps are time-consuming and labor-intensive. With ridge cap machines, manufacturers can drastically reduce production times. This efficiency translates into lower labor costs and allows for quicker project turnaround, meeting the demands of the fast-paced construction industry.

2. Consistency and Quality The automated processes of ridge cap machines ensure that each product is uniform in shape and size, meeting quality standards. This consistency is crucial in roofing projects, where even slight variations can lead to issues like leaks or structural weaknesses.

3. Versatility Modern ridge cap machines can accommodate various materials, including different types of metals and coatings. This versatility allows manufacturers to cater to diverse market needs, producing ridge caps that match various roofing styles and philosophies.

4. Cost-Effectiveness By reducing labor costs and minimizing waste through precise cutting and forming, ridge cap machines contribute to overall cost savings in production. The initial investment in this machinery is often recouped through increased efficiency and reduced material costs over time.

5. Enhanced Safety Automating the ridge cap production process reduces the risks associated with manual labor. Fewer workers are needed on the factory floor, minimizing exposure to potentially hazardous materials and equipment.

Conclusion

The ridge cap machine stands as a testament to technological advancement in the manufacturing sector. By enhancing efficiency, ensuring quality, and providing versatility, it has revolutionized how roofing components are fabricated. As the demand for high-quality roofing materials continues to grow, the ridge cap machine will undoubtedly play a pivotal role in meeting these needs, ultimately contributing to safer and more durable construction practices. As the construction industry evolves, embracing such innovations will be key to remaining competitive and responsive to market demands.