Introduction to Color Stone Coated Roof Tile Production Line

As the demand for sustainable and aesthetically appealing roofing solutions continues to rise, the production of color stone coated roof tiles emerges as a vital component in the construction industry. Offering a perfect blend of durability, beauty, and environmental sustainability, these roof tiles are increasingly being preferred by homeowners and builders alike. This article delves into the intricacies of the color stone coated roof tile production line, highlighting its components, processes, and benefits.

Components of the Production Line

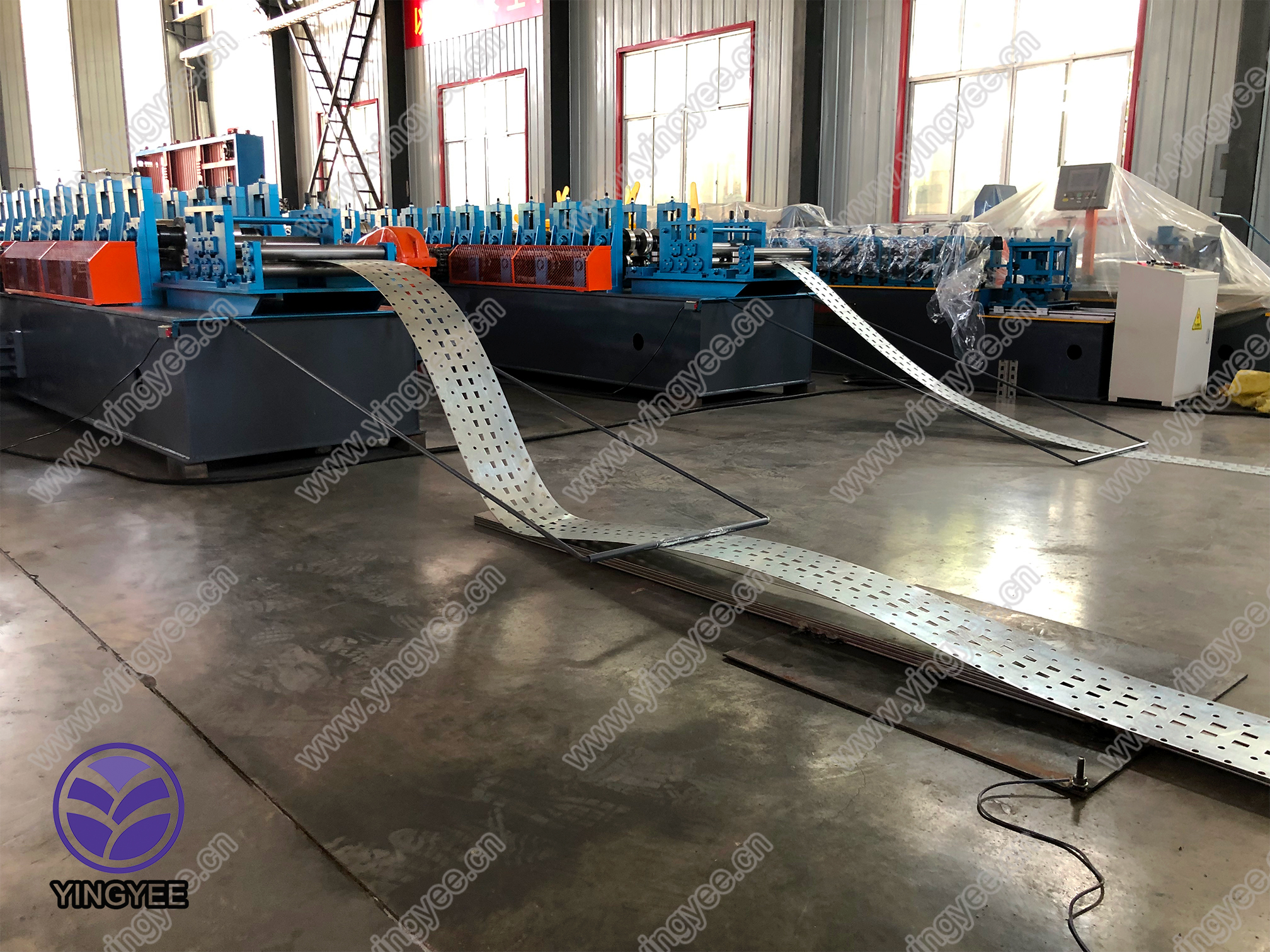

A typical color stone coated roof tile production line comprises several key components that work in unison to create high-quality roofing products. The primary elements include raw material processing equipment, forming machines, coating lines, and drying systems.

1. Raw Material Processing The production of color stone coated roof tiles begins with the selection and processing of raw materials. This includes high-quality steel sheets, which serve as the base, and natural stone granules, which provide color and texture. Other materials, such as adhesives and coatings, are also prepared during this stage.

2. Forming Machines Once the raw materials are ready, they are fed into forming machines that shape the steel sheets into various tile profiles. This step is crucial as it determines the final appearance and functionality of the tiles. Advanced forming technology ensures precision and consistency in the production process.

3. Coating Lines After the tiles are shaped, they undergo a coating process where they are covered with a layer of adhesive followed by the application of natural stone granules. The color of the granules can be customized, allowing for a variety of aesthetic options. This layer not only enhances the aesthetic appeal but also adds to the durability and weather resistance of the tiles.

4. Drying Systems Following the coating process, the tiles are subjected to drying systems that ensure proper adhesion of the stone granules to the tiles. This is a critical step that guarantees the longevity and performance of the finished product.

Production Process

The production process of color stone coated roof tiles is designed to be efficient and environmentally friendly

. It typically involves several stages

1. Preparation The first step involves collecting the materials and preparing them for processing. This includes cutting the steel sheets to size and sorting the stone granules based on color.

2. Shaping The prepared steel sheets are then fed into the forming machines where they are shaped into tiles. Precision engineering ensures uniformity in size and design.

3. Coating The shaped tiles are coated with adhesive and then sprinkled with colored stone granules. This layer is crucial for both aesthetic appeal and functional performance.

4. Curing and Drying After coating, the tiles are cured in drying systems. This process may involve elevated temperatures to enhance adhesion and ensure that the granules remain firmly attached.

5. Quality Control The final step in the production line is quality control. Each batch of tiles is rigorously tested for durability, weather resistance, and aesthetic appeal to ensure that they meet industry standards before distribution.

Benefits of Color Stone Coated Roof Tiles

Color stone coated roof tiles offer numerous benefits that make them an attractive option for both residential and commercial properties. They are highly durable, able to withstand harsh weather conditions, and come in a wide range of colors and designs. Additionally, their lightweight nature reduces the overall load on the building structure, making them easier to install. Importantly, these tiles are also environmentally friendly, as they often utilize recyclable materials and can contribute to energy efficiency in buildings.

Conclusion

The color stone coated roof tile production line represents an innovative approach in the roofing industry, combining aesthetics with functionality and sustainability. As technology continues to evolve, the production processes are likely to become even more efficient, paving the way for high-quality roofing solutions that meet the growing demands of modern construction.