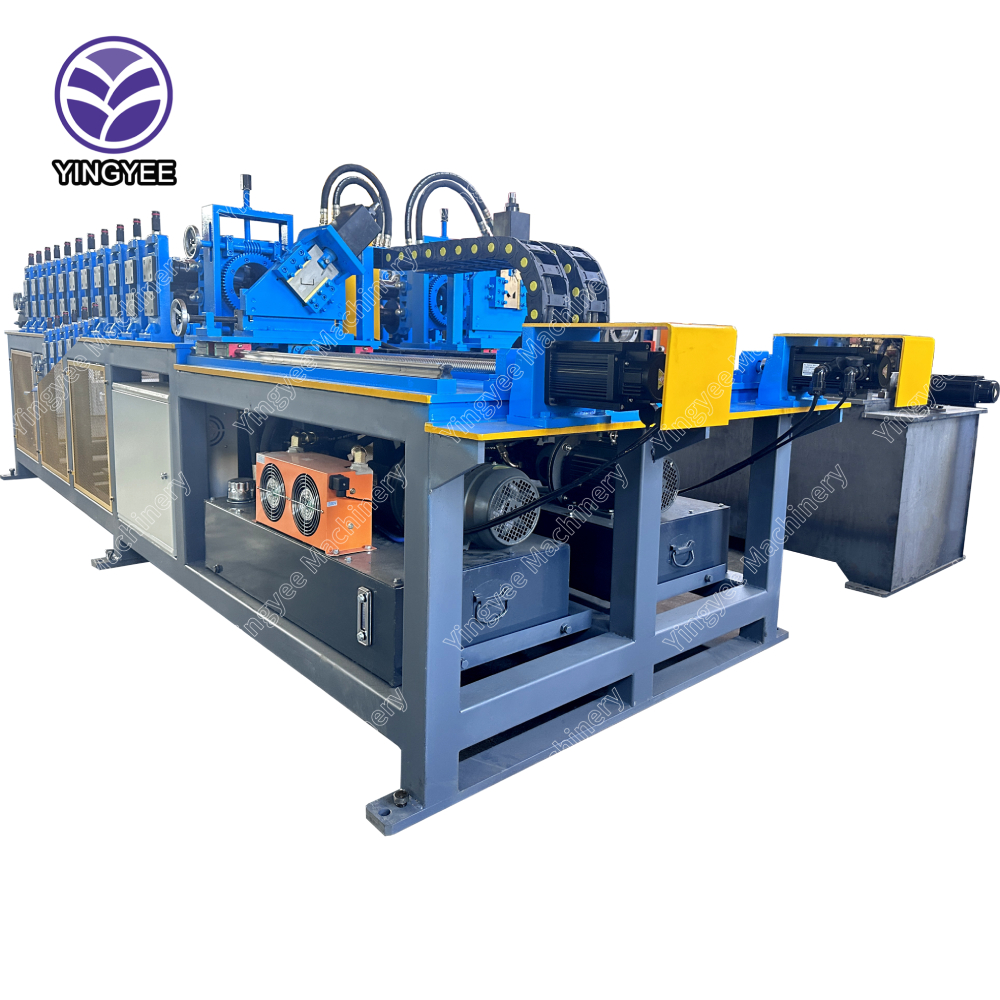

Multiple Profiler kënnen an der 40m / min Maschinn personaliséiert ginn. Eng Maschinn kann ee Profiler maachen (Stud a Camion kënnen an der selwechter Maschinn gemaach ginn), awer eng Maschinn ka verschidde Gréissten maachen.

The forming roller has high machining accuracy/precision, and the roller use material as Cr12 with high precision work ,heat treatment, uselife is more than 10 years.

berufflech stierwen Stol huet héich hardness an zouzedrécken Resistenz.

- De fäerdege Produkt huet héich Präzisioun, konsequent Längt a kee Twist.

The electrical parts (PLC, encoder, control system) are all famous Chinese brands, with long service life and low failure rates.

- Different sizes wall angles profiles can be produced in one machine. This machine has good production, low defective rate,Save cost.

No-stop cutting. Tracking moving cutting by servo control., speed 40 meters/min, high and stable.

- K Serie Reduzéierer ka mat enger Vielfalt vu Kraaftmotoren ugepasst ginn. Héich Kraaft, niddereg Kaméidi, laang Maschinn Liewen.

-

- De Gesamtkierper ass gutt ofgeschloss, an d'Guide Torrist Struktur ass staark an haltbar.

-

- Gutt Formungseffekt a korrekt Punchpositioun.

An hei sinn d'Parameteren vun der Maschinn.

|

Equipement Komponente

|

l 3 Tons Manual de-coiler*1

l Feeding guide system*1

l Mainly forming system*1

l Cutting servo moving cut(no stop cutting and with high speed) *1

l PLC control and touching screen*1

l Collection table *1

l Wrench*1

|

|

Netsic Spezifizéierung

|

|

Buedem Beräich vun Equipement

|

12 * 1*1.5meters

|

|

Spannungsparameter

|

wéi Client néideg

|

|

Total Muecht

|

17,5 kW an

|

|

Speed

|

0-40 m/min

|

|

Schnëtt Stil

|

Hydraulesch Schneidsystem

|

|

Technesch Parameter

|

|

Material

|

Thickness: 1.5mm

Effektiv Breet: No Zeechnen

|

|

Haaptsächlech Formatioun System

|

1.Main power: 5.5+5.5kw

2.Wall panel: standing plate with iron casting

3.Forming speed: tracking cut, speed is 0-40m/min

4.Shaft material and diameters: #45 steel and 60mm

5.Roller material:: Cr12 with well heat treatment ,58-62

6.Forming Steps: 12 steps for forming

7.Ugedriwwe: Kette

|

|

Ausschneiden Deel

|

Hydraulic cutting system

Material: Cr12

Hydraulic Cutting Power: 7.5kw

|

|

Empfang Dësch

|

5 Meter laang

|