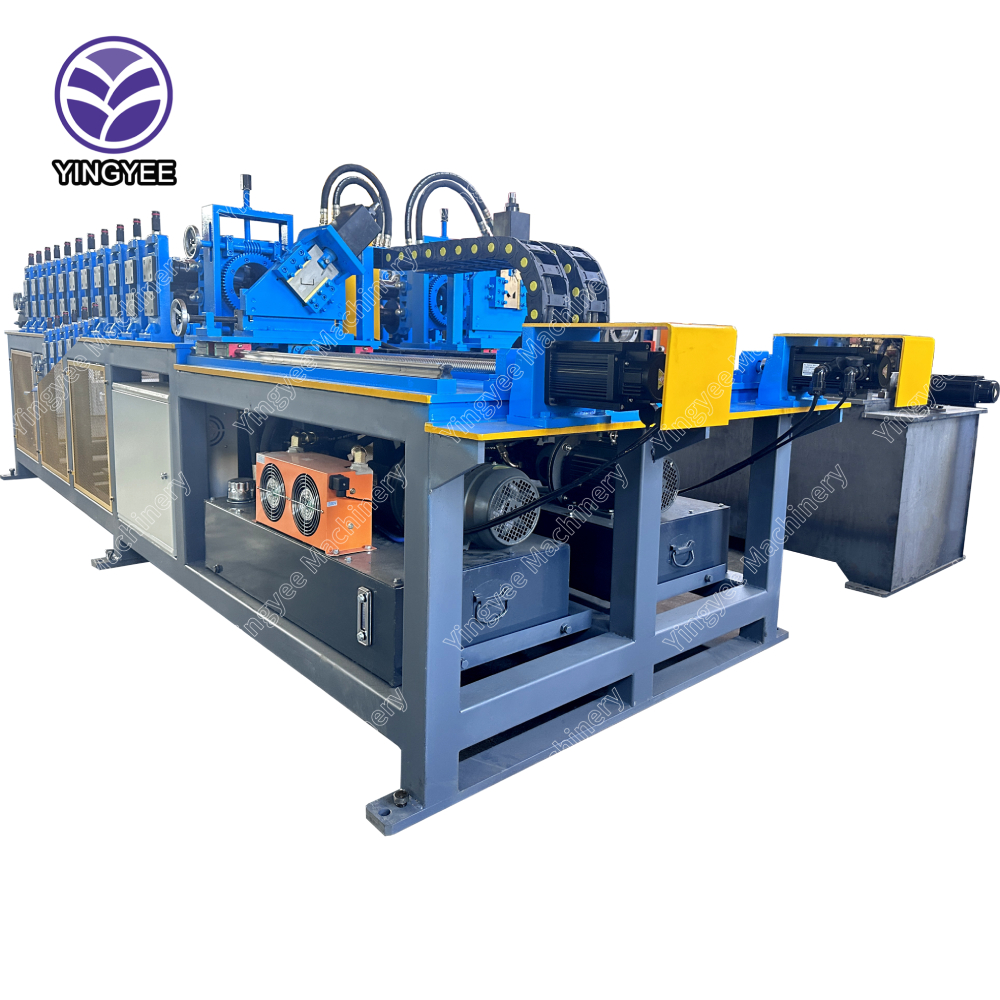

Multiple profiles can be customized in the 40m/min machine. One machine can make one profiles (stud and truck can be made in same one machine), but one machine can make multiple size.

The forming roller has high machining accuracy/precision, and the roller use material as Cr12 with high precision work ,heat treatment, uselife is more than 10 years.

professional die steel has high hardness and wear resistance.

- The finished product has high precision, consistent length and no twist.

The electrical parts (PLC, encoder, control system) are all famous Chinese brands, with long service life and low failure rates.

- Different sizes wall angles profiles can be produced in one machine. This machine has good production, low defective rate,Save cost.

No-stop cutting. Tracking moving cutting by servo control., speed 40 meters/min, high and stable.

- K series reducer can be matched with a variety of power motors. High strength, low noise, long machine life.

-

- The overall body is well finishing, and the guide torrist structure is strong and durable.

-

- Good forming effect and accurate punching position.

And here are the parameters of the machine.

|

Equipment component

|

l 3 Tons Manual de-coiler*1

l Feeding guide system*1

l Mainly forming system*1

l Cutting servo moving cut(no stop cutting and with high speed) *1

l PLC control and touching screen*1

l Collection table *1

l Wrench*1

|

|

Basic specification

|

|

Floor area of equipment

|

12 * 1*1.5meters

|

|

Voltage parameter

|

as customer required

|

|

Total power

|

17.5kw

|

|

Speed

|

0-40m/min

|

|

Cut style

|

Hydraulically cutting system

|

|

Technical parameter

|

|

Material

|

Thickness: 1.5mm

Effective width:According to drawing

|

|

Mainly forming system

|

1.Main power: 5.5+5.5kw

2.Wall panel: standing plate with iron casting

3.Forming speed: tracking cut, speed is 0-40m/min

4.Shaft material and diameters: #45 steel and 60mm

5.Roller material:: Cr12 with well heat treatment ,58-62

6.Forming Steps: 12 steps for forming

7.Driven: Chain

|

|

Cutting part

|

Hydraulic cutting system

Material: Cr12

Hydraulic Cutting Power: 7.5kw

|

|

Receiving table

|

5 meters long

|