In today's fast-paced metal manufacturing industry, efficiency and precision in material processing are non-negotiable. YingYee Machinery's Slitting Production Line represents the gold standard in coil processing technology, transforming wide metal coils into multiple narrow strips with surgical precision.

Our Slitting Production Line excels through its adaptive slitting technology, capable of processing various materials including cold-rolled steel, stainless steel, aluminum, and coated coils with thicknesses from 0.1mm to 6.0mm. The servo-controlled loop system maintains optimal tension throughout the process, while the precision rotary shear delivers burr-free edges that eliminate secondary processing.

Slitlína fyrir málm í mörgum stærðum og efnum. Þessi hefðbundna framleiðslulína getur gert galvaniseruðu, heitvalsaða, ryðfríu stáli slitting með þykkt 0,3mm-3mm og hámarksbreidd 1500. Lágmarksbreidd má skipta í 50mm. Það er hægt að gera það þykkara og þarf sérstaka aðlögun.

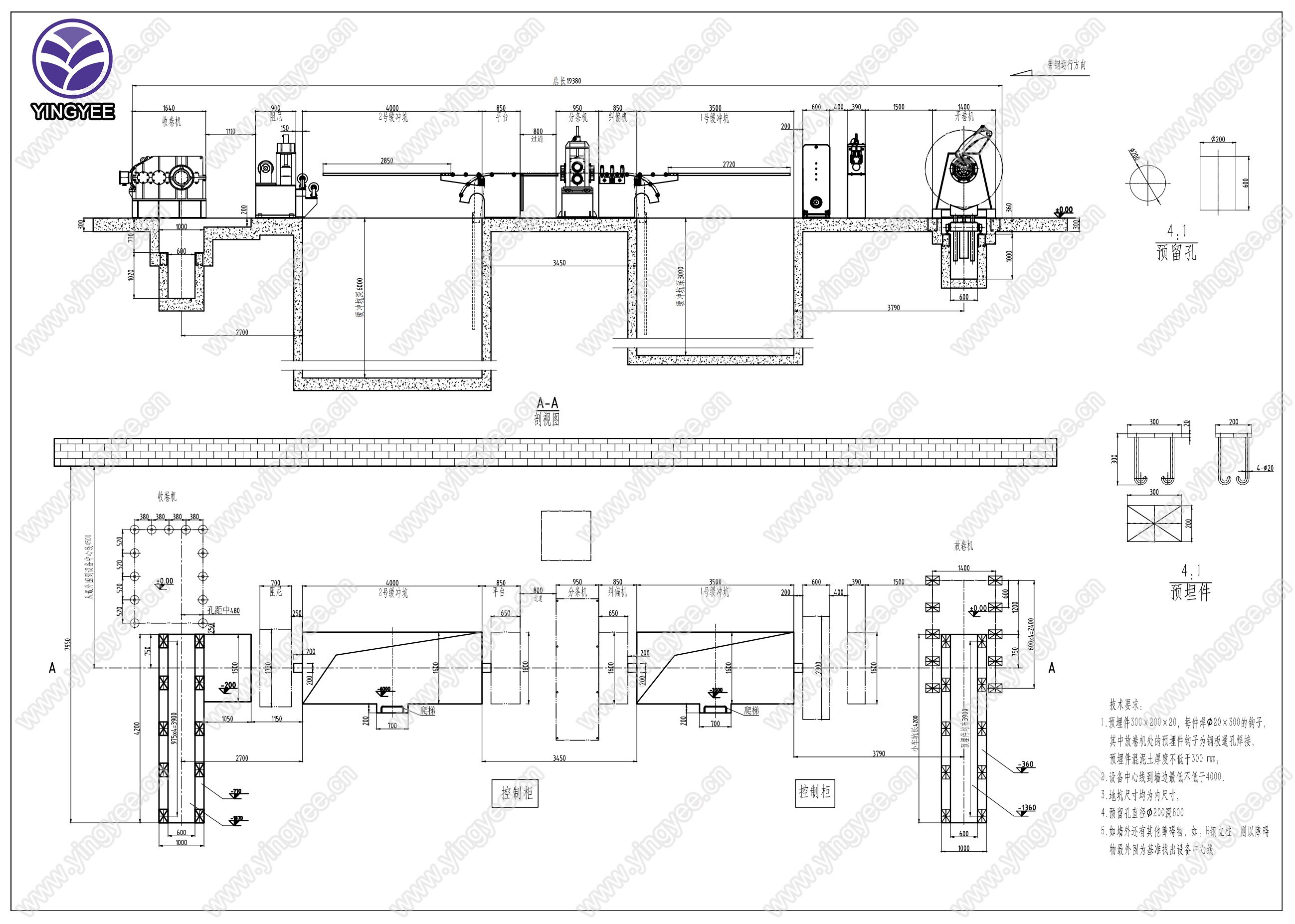

The operational excellence of our Slitting Production Line begins with automated coil loading, where overhead cranes or hydraulic arms position master coils with millimeter precision. The precision uncoiler features dynamic braking to maintain perfect tension as material enters the multi-roller leveling system, which removes all coil set and crossbow.

As the material progresses through the dual-side trim shear, the laser-guided positioning system ensures exact strip width configuration. The heart of the system - our patented rotary slitter - operates with vibration-dampened arbors that maintain cutting precision even at maximum speeds. Final processing includes automatic strip separation and tension-controlled rewinding onto individual mandrels, with optional edge-lapping for perfect coil formation. The entire process is monitored by predictive maintenance sensors that anticipate wear before it affects product quality.

The output from our Slitting Production Line serves as critical input for numerous advanced manufacturing processes:

Automotive Components: Producing precision strips for seat frames, brake components, and structural parts

Electronics Manufacturing: Creating narrow coils for connector pins, shielding cans, and battery components

Construction Materials: Preparing strip coils for roofing nails, drywall beads, and framing components

Appliance Production: Supplying exact-width materials for refrigerator panels, oven cavities, and washer drums

For metal service centers and precision manufacturers, our Slitting Production Line offers three transformative advantages that redefine productivity benchmarks. The intelligent edge-trimming system automatically adjusts to material variations, maintaining perfect edge quality even when processing coated or sensitive materials.

A breakthrough feature is the dynamic width control that enables on-the-fly width adjustments without stopping production, a critical capability for just-in-time manufacturing. The integrated vision inspection system continuously monitors strip quality, detecting and flagging any edge defects or surface imperfections in real-time. Most importantly, our line's quick-change tooling system allows complete slitting head replacement in under 15 minutes - a game-changing advantage for processors handling diverse product mixes.