In today's competitive construction and security industry, high-quality roller shutter doors are in constant demand. YingYee Machinery and Technology Service Co., Ltd. specializes in manufacturing roller shutter door roll forming machines that deliver precision, durability, and efficiency. Our machines are engineered to produce flawless shutter profiles, ensuring smooth operation and long-lasting performance. With years of expertise in metal processing equipment, we provide solutions that meet global standards, helping businesses enhance their production capabilities while maintaining cost-effectiveness.

The roller shutter door roll forming machine is designed to handle various materials, including galvanized steel, aluminum, and other alloys, making it versatile for different market needs. Its automated features reduce manual labor, while the precision-guided rollers ensure consistent thickness and shape for every slat. Whether for commercial, industrial, or residential applications, our machine guarantees high output with minimal waste, making it an ideal choice for manufacturers aiming for scalability and reliability.

Sporöskjulaga holu rúllumyndandi vél, hún er vinsæl í Norður-Ameríku og Suður-Ameríku.

Special design of oval hole , 3 stations of punching, edging and flanging at the same time, accurate hole size (152 * 25MM), accurate punching position, no half hole, flanging does not hurt finger

Það er vinsælt í Norður-Ameríku og Suður-Ameríku. Það er hentugur fyrir stórar verslunarmiðstöðvar og stórmarkaðir

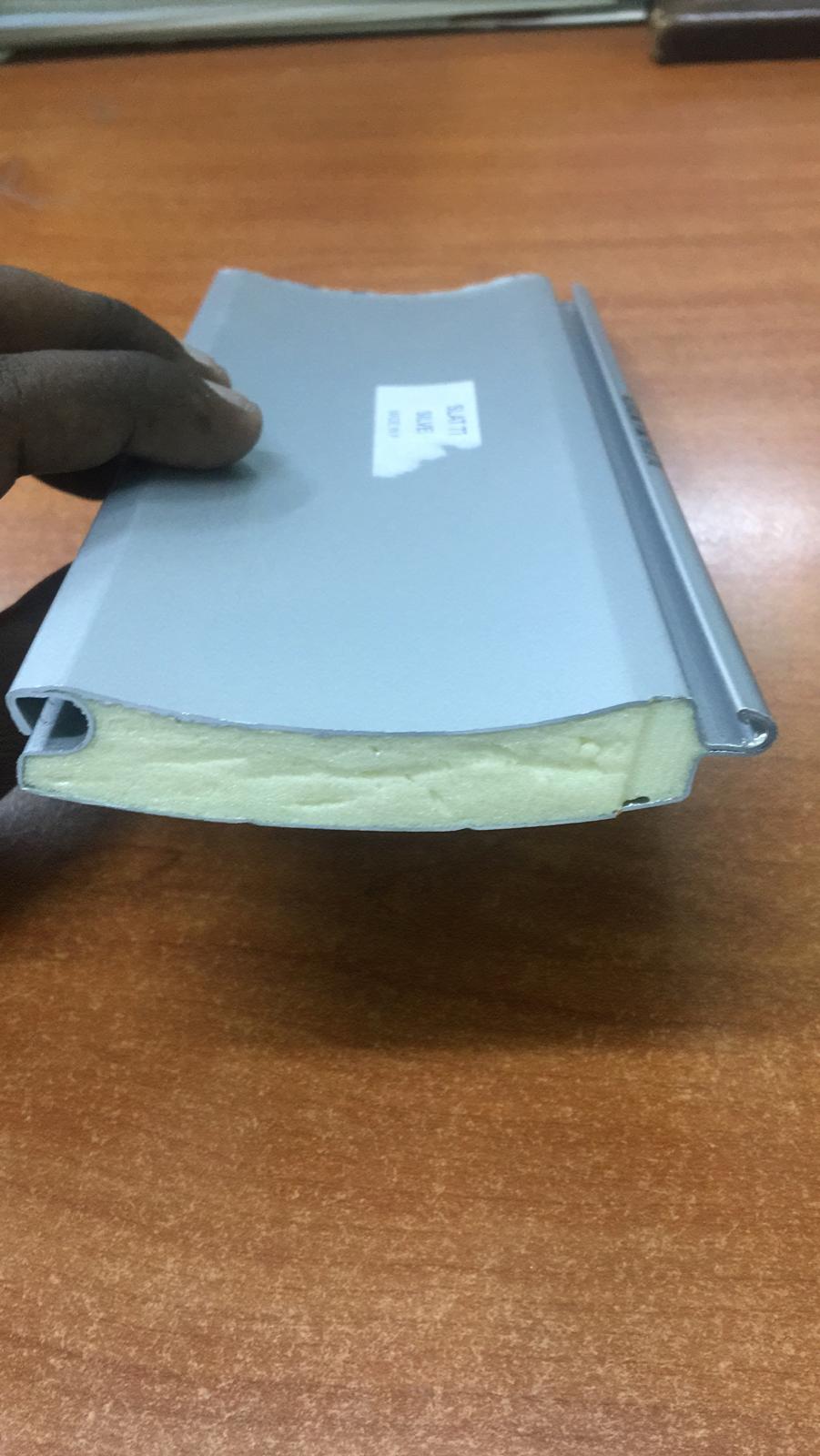

PU rúllumyndunarvél, góð mótunar- og inndælingaráhrif. Og við útvegum vél með tveimur hraða, 15m/mín og 30m/mín sem valkost.

Sporöskjulaga holu rúlluhurð rimlakúlumyndunarvél, hraði með gati 5m/mín, hraði án gats 9m/mín.

Rúlluhurð með litlum holu rúllumyndunarvél með þroskaðri tækni, vinnu með mikilli nákvæmni.

Hurðarvél með rúlluhurð með hraða 30m/mín., hraðauppbygging, góð myndunaráhrif með rétta hluta, það getur lofað rimlan hnoðað.

When selecting a roller shutter door roll forming machine, quality and performance are paramount. YingYee Machinery’s machine excels due to its robust construction, advanced automation, and energy-efficient operation. Unlike conventional models, our machine incorporates a high-precision servo system that adjusts speed and pressure automatically, ensuring flawless forming without material distortion. This results in perfectly aligned shutter slats that fit seamlessly, reducing installation time and improving door functionality.

Another key advantage is the machine’s adaptability. It can produce a variety of shutter profiles, from standard industrial doors to customized designs for architectural projects. The quick-change mold system allows operators to switch between different profiles effortlessly, maximizing productivity. Additionally, our machine features an intelligent control panel that monitors production in real time, alerting operators to any potential issues before they affect output quality.

.

Innovation is at the core of YingYee Machinery’s roller shutter door roll forming machine, which integrates the latest technological advancements to optimize performance. One standout feature is the PLC (Programmable Logic Controller) system, which allows for fully automated operation with minimal human intervention. This not only enhances precision but also significantly reduces labor costs, making it a cost-effective solution for large-scale production.

The machine also includes a hydraulic cutting system that ensures clean, burr-free edges on every shutter slat, eliminating the need for secondary processing. This feature is particularly beneficial for manufacturers who prioritize speed and quality. Furthermore, the reinforced frame and heavy-duty rollers are built to withstand continuous operation, ensuring longevity even in high-volume production environments.

For businesses looking to expand their market reach, our machine supports customization, enabling the production of shutters with unique patterns, colors, and thicknesses. This flexibility makes it an excellent choice for clients catering to diverse architectural and security demands. Whether for fire-resistant shutters, noise-insulated doors, or high-security barriers, our roller shutter door roll forming machine delivers unmatched versatility.

For manufacturers and suppliers in the door industry, investing in a high-performance roller shutter door roll forming machine is a strategic move toward sustainable growth. YingYee Machinery’s machine not only boosts production capacity but also enhances product quality, helping businesses secure more contracts and expand into new markets. Its low maintenance requirements and energy-efficient operation further reduce operational costs, ensuring a higher return on investment over time.

The global demand for roller shutters continues to rise, driven by increasing security concerns and the need for energy-efficient building solutions. Our machine empowers manufacturers to meet this demand efficiently, producing shutters that comply with international safety and quality standards. By partnering with YingYee Machinery, businesses gain access to reliable equipment, expert technical support, and continuous innovation—key factors for long-term success in the competitive metal processing industry.