Understanding T-Bar Ceiling Frame Making Machines

In the realm of modern construction and interior design, the T-bar ceiling system has become a popular choice due to its versatility, ease of installation, and aesthetic appeal. Central to the production of T-bar ceilings is the T-bar ceiling frame making machine, a specialized piece of equipment that streamlines the manufacturing process and ensures high-quality output. This article delves into the functionalities, advantages, and operational considerations associated with T-bar ceiling frame making machines.

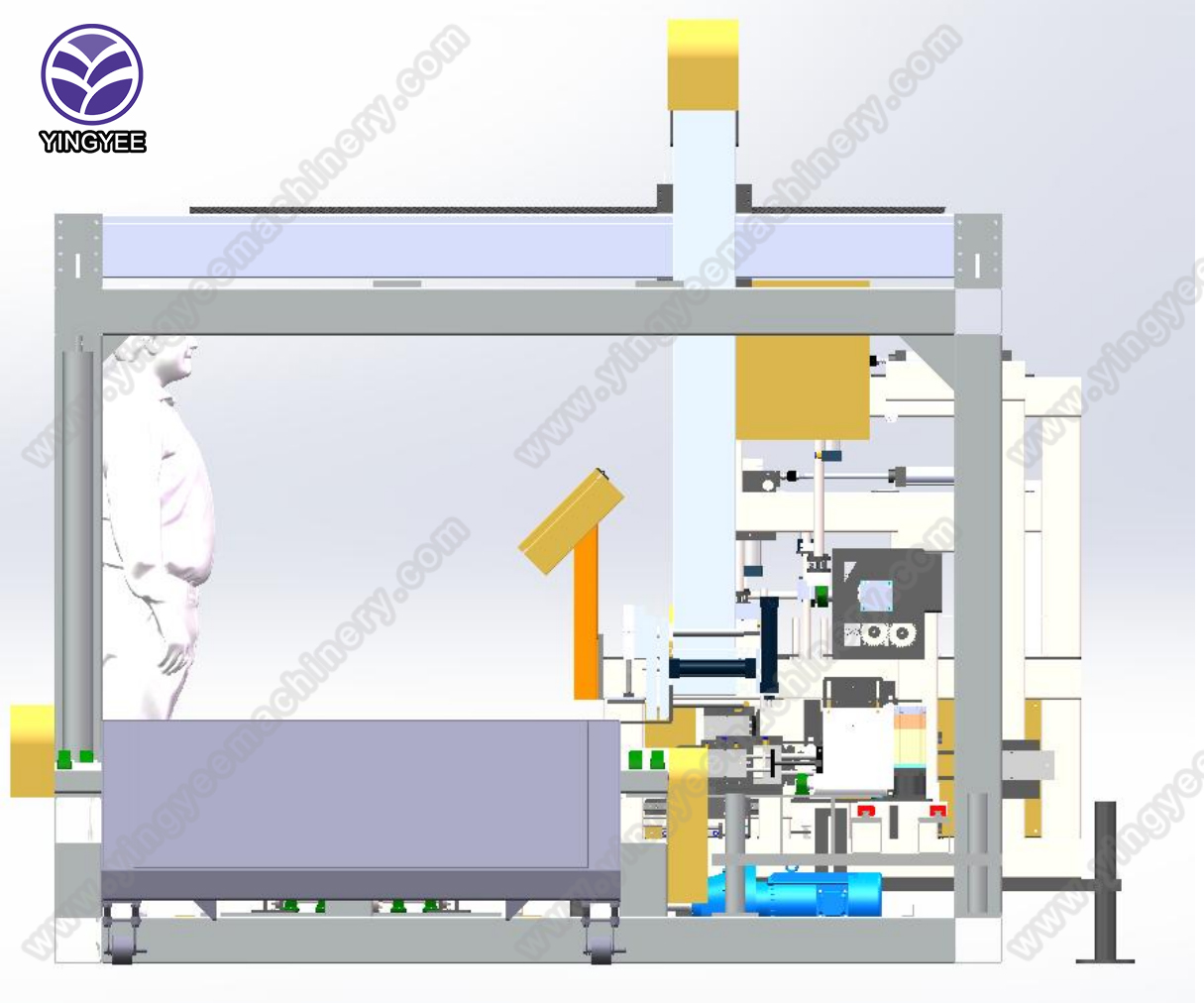

Concept and Functionality

A T-bar ceiling, often referred to as a drop ceiling or suspended ceiling, consists of a grid-like framework that supports ceiling tiles. The frame is typically made from lightweight materials such as aluminum or galvanized steel, ensuring durability while being easy to handle. The T-bar ceiling frame making machine is designed to fabricate various components of this ceiling system, including T-bars, cross tees, and perimeter trim.

The operation of the machine involves several stages, including material feeding, cutting, bending, and assembling. Advanced models feature automation, allowing for precise control over dimensions and reducing human error. Additionally, many machines are equipped with digital interfaces, enabling operators to easily adjust settings for different specifications, thus accommodating various design preferences.

Advantages of T-Bar Ceiling Frame Making Machines

1. Efficiency A key benefit of using a T-bar ceiling frame making machine is the speed at which it produces materials. Automated processes significantly reduce the time required to manufacture frame components, allowing construction teams to accelerate project timelines.

2. Quality Control Machines ensure consistent quality in every piece produced, as they are designed to adhere to exact specifications. This uniformity is critical in ceiling installation, where misaligned components can lead to aesthetic and functional issues.

3. Cost-Effectiveness By mechanizing the manufacturing process, companies can lower labor costs and minimize material wastage. Over time, the return on investment (ROI) for acquiring a T-bar ceiling frame making machine can be substantial, particularly for businesses with high production demands.

4. Customization Modern machines are capable of producing various designs and dimensions. This adaptability allows manufacturers to cater to specific client needs and respond to market trends without requiring substantial downtime for recalibration.

Operational Considerations

While T-bar ceiling frame making machines offer numerous advantages, several operational considerations should not be overlooked

- Maintenance Regular maintenance is essential to ensure optimal performance. This includes routine cleaning, lubrication of moving parts, and timely replacement of worn components.

- Operator Training To maximize the efficiency and safety of the machine, operators must be adequately trained. Understanding the machine's controls, safety protocols, and troubleshooting techniques is crucial for preventing operational mishaps.

- Material Selection The choice of raw materials can significantly impact the quality of the final product. Operators should ensure that materials are compatible with the machine specifications to minimize production issues.

- Safety Measures Proper safety measures must be implemented to protect operators from potential hazards associated with the machine. This includes using safety guards, emergency shut-off systems, and personal protective equipment.

Conclusion

T-bar ceiling frame making machines are integral to the contemporary construction and interior design landscape. By streamlining the production of ceiling frames, these machines enhance efficiency, ensure quality, and allow for customization. As the demand for suspended ceilings continues to grow, investing in advanced T-bar ceiling frame making technology can provide a competitive edge in the market. For contractors and builders, understanding the capabilities and operational requirements of these machines is essential for successful projects that meet the needs of clients while maintaining high standards of quality and safety.