Investing in a hydraulic thread rolling machine is a decision influenced by various factors, ranging from machine capabilities to budget constraints. A primary consideration is understanding the price range and what defines the cost structure of these machines, ensuring that buyers invest wisely while maximizing return on investment.

Hydraulic thread rolling machines are pivotal in manufacturing, providing precision and efficiency. The cost of these machines can vary widely, largely dependent on specifications, features, and the technology incorporated. Entry-level models may start around $10,000 to $15,000, suitable for small-scale operations or businesses just venturing into thread rolling. These basic models typically offer manual operation or semi-automatic features, adequate for lower volume production.

Mid-range machines, falling between $20,000 to $50,000, incorporate more advanced automation, increasing efficiency and reducing the need for extensive manual intervention. They often offer enhanced speed, accuracy, and capability to handle larger ductile materials. These models are preferred by mid-sized enterprises aiming to strike a balance between cost and production demands.

High-end hydraulic thread rolling machines, which can exceed $50,000, are designed for large industrial settings demanding high volume, precision, and efficiency. They incorporate the latest technology, such as CNC controls, offering versatility and adaptability across a wide range of threading processes. These machines ensure reduced production time and waste, translating to long-term cost savings and operational excellence.

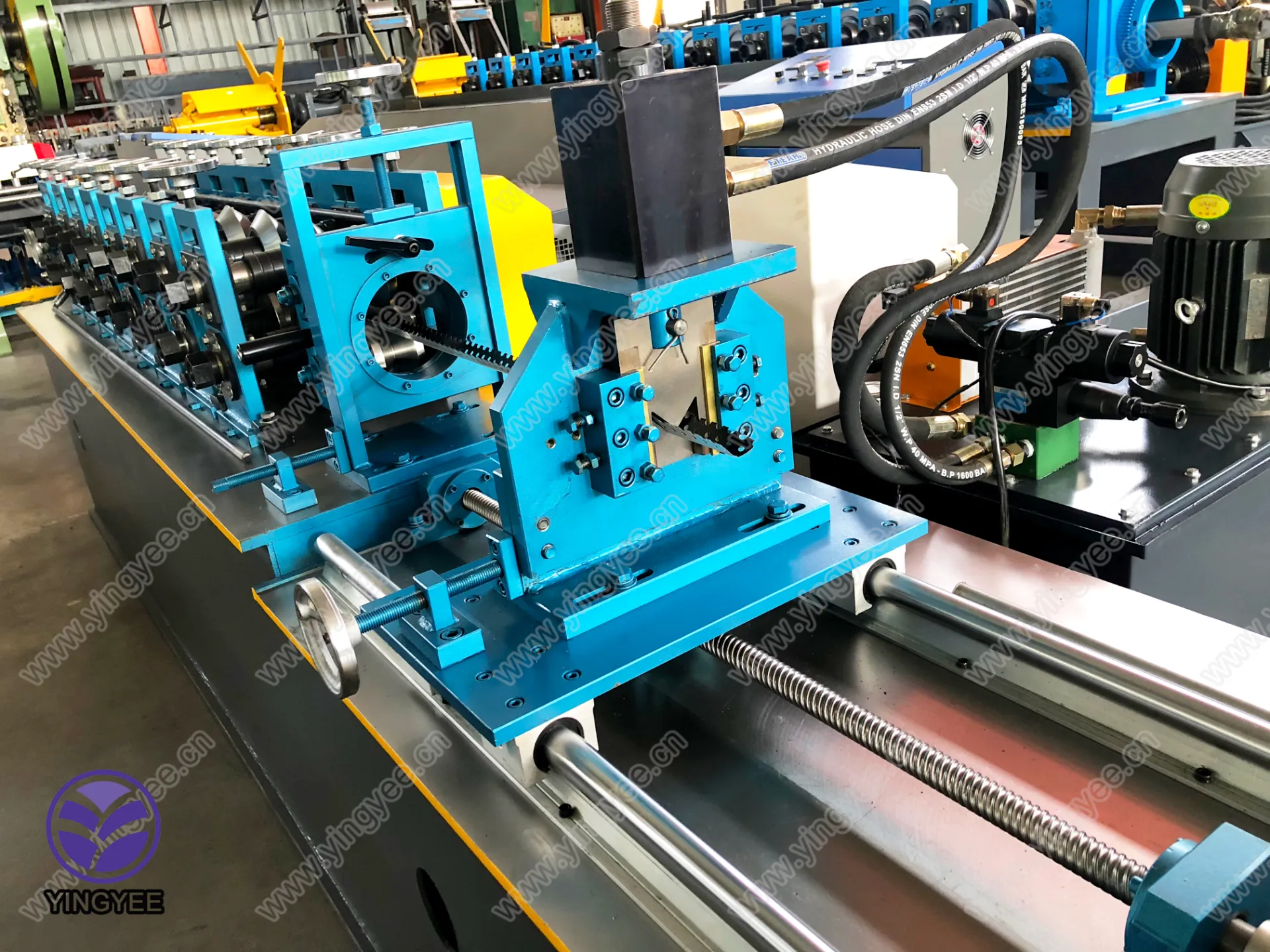

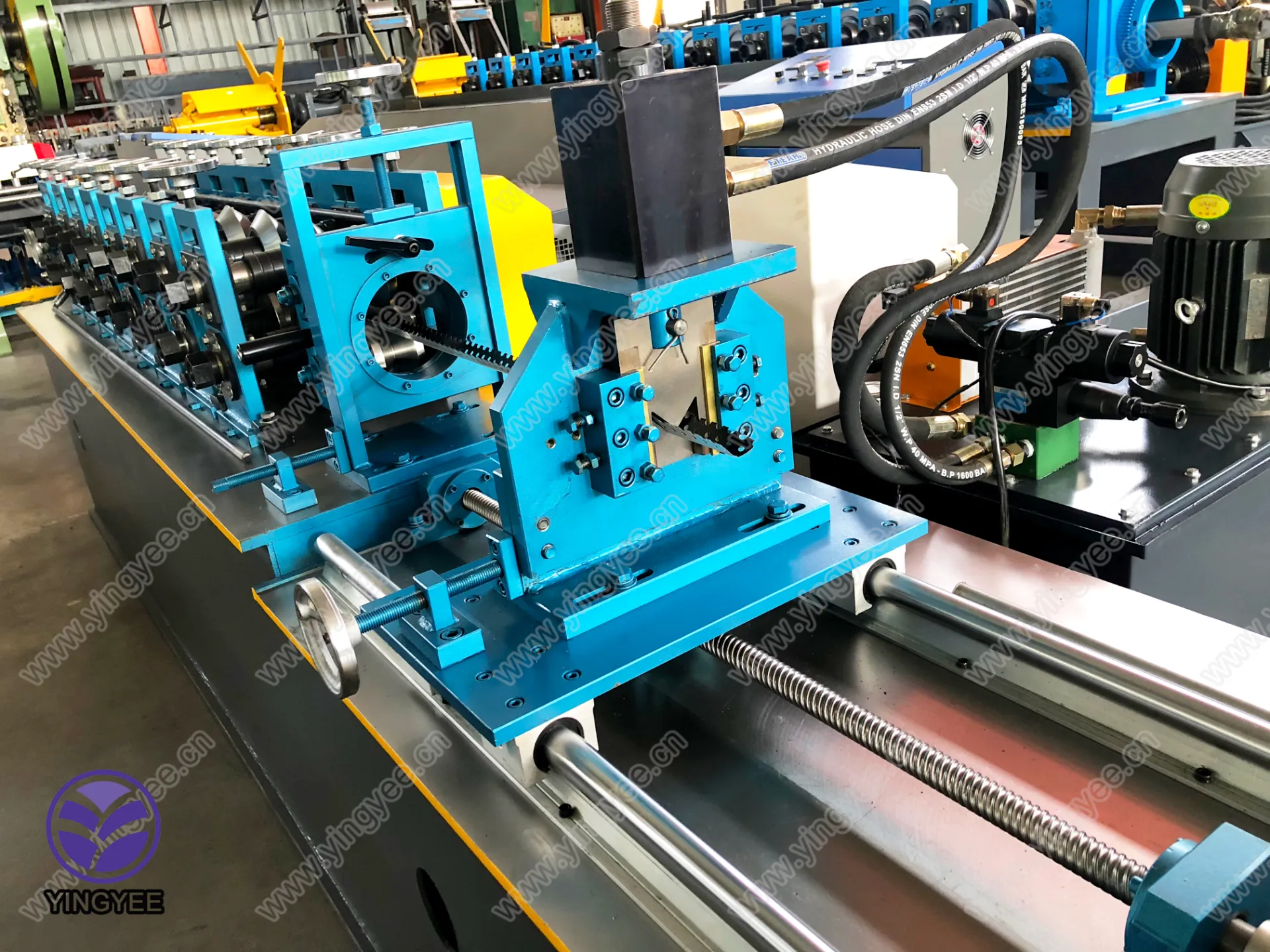

hydraulic thread rolling machine price

When determining the best machine for your needs, consider the threading capacity, precision requirements, operational speed, and material compatibility. Assessing these factors in conjunction with the machine price helps ensure that the investment aligns with production goals and budgetary allowances. Additionally, buyers should evaluate the after-sales service, warranty, and customer support provided, as these attributes can significantly influence the overall cost-effectiveness and reliability of the machine.

It's worthwhile to consult industry insights and reviews from other users who have handled similar machinery to gauge performance and satisfaction levels. Engaging with reputable manufacturers and suppliers who emphasize quality, innovation, and customer support is crucial for making an informed decision. These entities typically offer comprehensive guides and consultations, enabling clients to tailor their investments to specific operational needs.

Moreover, investigating financing options available for such equipment can alleviate immediate financial burdens. Many manufacturers offer flexible purchasing terms, including leasing or installment plans, allowing businesses to integrate advanced technology without straining their capital reserves.

Ultimately, selecting the right hydraulic thread rolling machine involves a blend of technical evaluation and financial planning. By understanding the distinct categories and corresponding price ranges, businesses can ensure a cost-effective investment that elevates their production capabilities while maintaining fiscal responsibility.