The Role of Downpipe Roll Forming Machines in Manufacturing

In the modern construction and manufacturing industries, the efficiency and precision of producing metal components are paramount. One of the innovative technologies employed to enhance production is the downpipe roll forming machine. This specialized equipment is designed to create downpipes and other related components with precision and speed, serving a vital role in various applications across multiple sectors.

Understanding Downpipe Roll Forming Machines

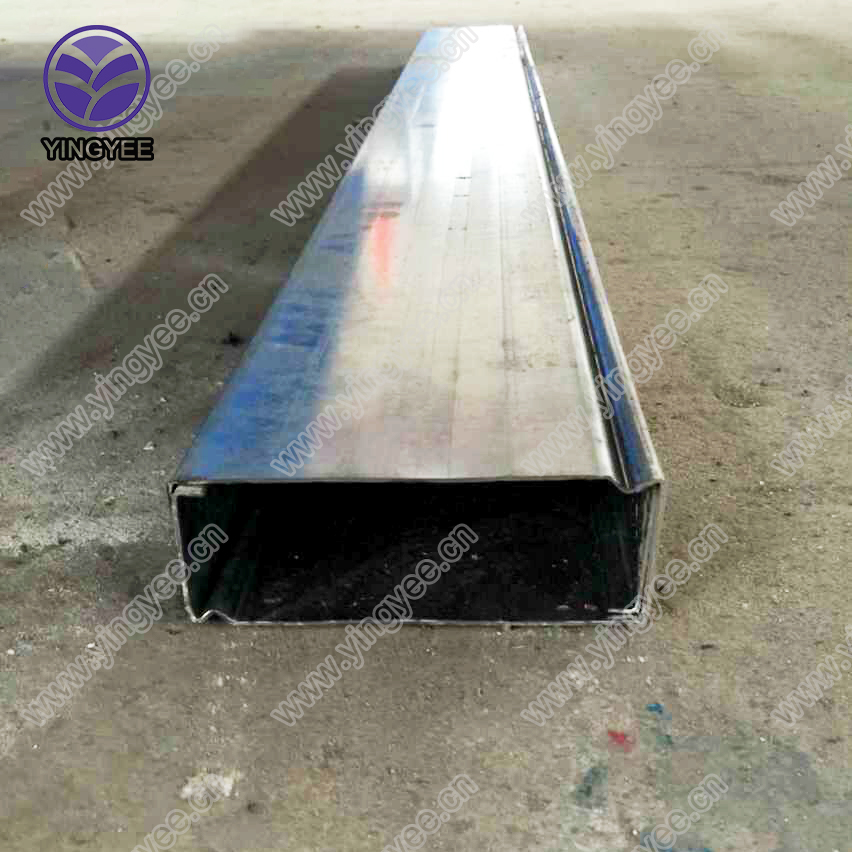

A downpipe roll forming machine is a type of machinery that utilizes a continuous roll forming process to produce downpipes, which are essential for directing rainwater away from roofs and facades. These machines take flat steel or aluminum coils as input and shape them into desired profiles through a series of rollers. The process not only improves the structural integrity of the pipes but also offers superior aesthetics compared to traditional manufacturing methods.

Key Features and Benefits

One of the most significant advantages of downpipe roll forming machines is their ability to produce a high volume of downpipes quickly and with consistent quality. The automated nature of these machines reduces human error and increases production efficiency. The technology allows manufacturers to customize the dimensions and profiles of the downpipes to meet specific project requirements, ensuring versatility in usage.

Additionally, roll forming is a cost-effective process. Since it optimizes material usage by minimizing waste and allowing for longer continuous lengths of product, companies can enjoy lower material costs while maintaining high-quality output. Furthermore, the durability and strength of the profile produced through this method make it a wise investment for long-term use.

The Manufacturing Process

The operation of a downpipe roll forming machine begins with feeding the metal coil into the machine, where it is straightened and cut to the desired length. As the coil moves through a series of carefully configured rollers, each roller gradually bends the metal into the final downpipe shape. The precision of each roller station is critical, as it determines the accuracy of the final product.

Once the profile is formed, the downpipe may undergo additional processes such as punching holes for drainage or surface treatments to enhance resistance to corrosion and environmental damage. The versatility of roll forming machines allows for integration with various finishing processes, giving manufacturers the ability to produce a complete product in one continuous operation.

Applications in Construction

Downpipes manufactured by these machines are used in numerous construction applications, ranging from residential buildings to large commercial projects. By effectively directing rainwater away from walls and foundations, downpipes help prevent water damage and ensure the longevity of structures. The aesthetic appeal of customized downpipes also contributes to the overall design of modern buildings.

In addition, the energy efficiency of roll forming machines aligns with the growing trend toward sustainable practices in manufacturing. By minimizing waste and maximizing resource utilization, these machines support environmental goals while ensuring high-quality production.

Conclusion

Downpipe roll forming machines represent a significant advancement in manufacturing technology. By streamlining the production process and ensuring consistent quality, these machines play a crucial role in the construction industry. As the demand for efficient, aesthetically pleasing, and durable components continues to grow, the impact of downpipe roll forming machines will undoubtedly become even more pronounced, further revolutionizing the way we approach construction and design projects. With ongoing innovations in this field, the future looks promising for manufacturers who embrace this technology.