The Emergence of China’s PU Sandwich Panel Line Revolutionizing Construction and Insulation

In recent years, China has become a pivotal player in the global construction materials industry, particularly with the introduction and advancement of PU (Polyurethane) sandwich panel production lines. This innovative technology is not only reshaping the construction sector but also enhancing energy efficiency and environmental sustainability.

Understanding PU Sandwich Panels

PU sandwich panels comprise two outer layers, typically made of steel or aluminum, and an inner core of rigid polyurethane foam. This composite structure offers exceptional insulation properties, fire resistance, and structural integrity, making it ideal for a variety of applications, including industrial buildings, refrigeration units, and even residential homes.

The demand for energy-efficient building materials has intensified in light of global climate challenges. PU sandwich panels deliver superior thermal insulation, reducing heating and cooling costs while minimizing energy consumption. This is particularly critical in regions with extreme temperatures, where maintaining a stable indoor climate is essential.

The Production Line in China

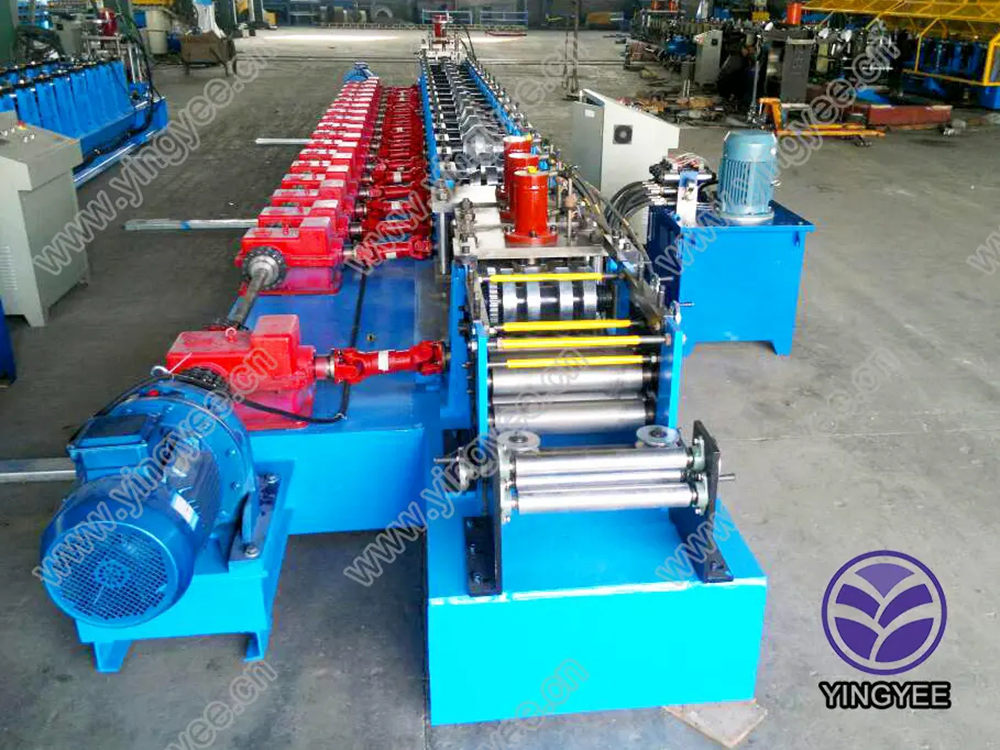

China's PU sandwich panel production line technology has made significant strides in recent years. State-of-the-art machinery and automated systems enable manufacturers to produce high-quality panels at scale. The production process involves several stages

1. Material Preparation Raw materials, including steel sheets and polyurethane foam, are carefully selected for their quality and compatibility.

2. Foam Injection Polyurethane foam is injected between the two outer layers in a controlled environment. This is a crucial step, as the quality of the foam directly affects the insulation properties and structural strength of the finished panel.

3. Pressing and Curing The sandwich structure is then pressed to ensure proper bonding and curing of the foam. This process not only enhances durability but also ensures that the panels maintain their shape and integrity over time.

Benefits of PU Sandwich Panels

The rise of PU sandwich panel lines in China has several notable advantages

- Energy Efficiency The panels’ exceptional thermal insulation properties reduce energy consumption, leading to lower utility bills and a reduced carbon footprint.

- Rapid Installation PU sandwich panels are lightweight and easy to handle, allowing for faster installation. This can significantly reduce labor costs and construction timelines.

- Versatility These panels can be used in various applications, including walls, roofs, and cold storage facilities. Their versatility makes them suitable for numerous sectors, including industrial, residential, and commercial construction.

- Sustainability With a growing focus on sustainable building practices, PU sandwich panels offer an eco-friendly solution. Their energy efficiency contributes to lowering greenhouse gas emissions, and the materials used can often be recycled.

Challenges and Future Outlook

Despite the advantages, the PU sandwich panel industry does face challenges. Fluctuations in raw material prices can affect production costs, and competition among manufacturers remains fierce. Additionally, there are ongoing concerns regarding the environmental impact of polyurethane production itself.

Nevertheless, the future of China’s PU sandwich panel line looks promising. With continual advancements in technology and a commitment to sustainable practices, the industry is poised for growth. As global demand for energy-efficient and environmentally friendly building materials continues to rise, China’s innovative solutions will likely lead the way.

Conclusion

In summary, the development of PU sandwich panel production lines in China signifies a significant advancement in construction technology. Offering a blend of energy efficiency, rapid installation, and versatility, these panels are revolutionizing how structures are built today. As the industry evolves, it is expected to play a critical role in addressing modern construction challenges while promoting a more sustainable future. With continued innovation and investment, China's PU sandwich panels are set to become a staple in the construction materials market worldwide.