|

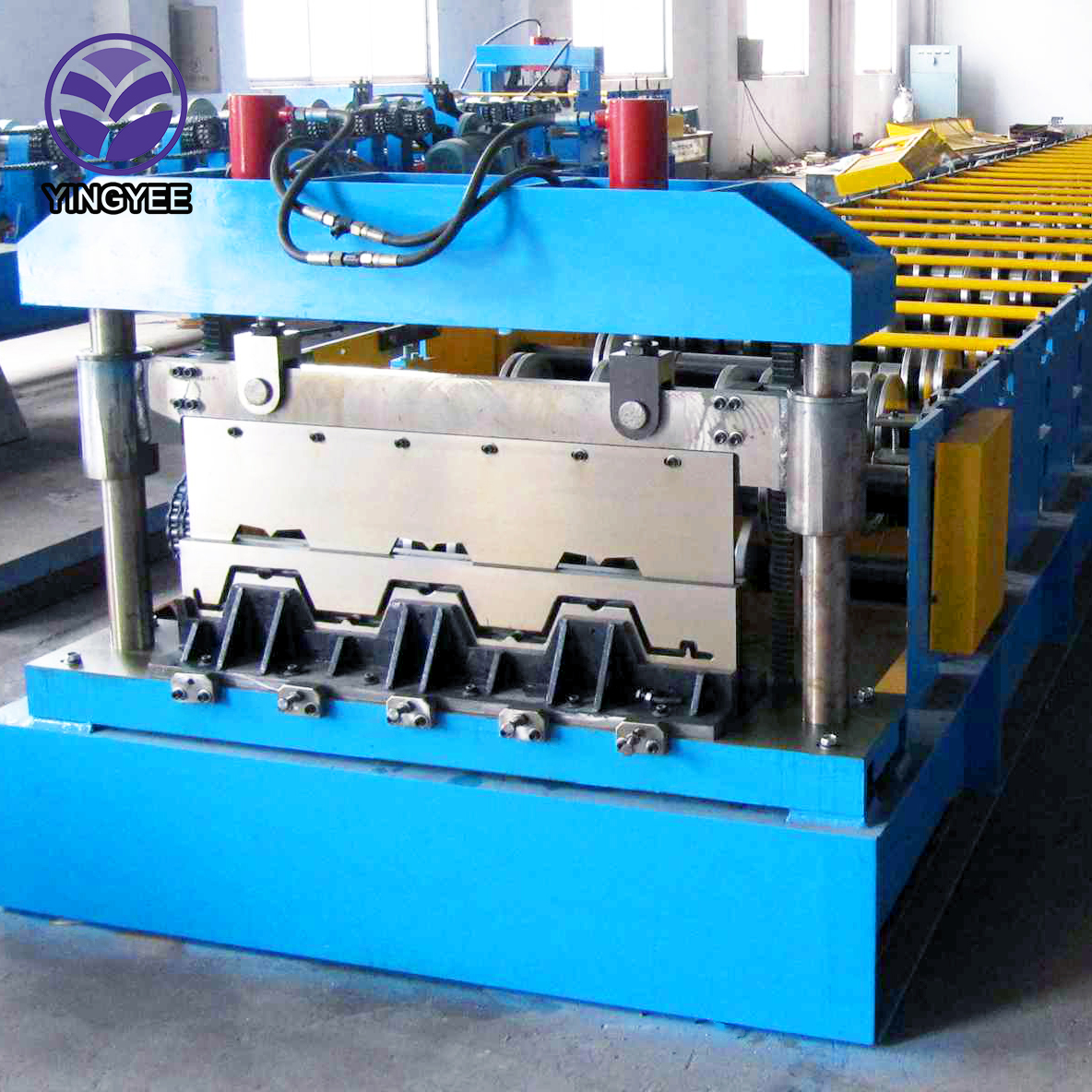

1. Material thickness range:0.3-0.8mm

2. Feeding width :depend on drawing

3. Effective width:ibr 914.4mm and corrugated 854mm

4. Speed: 30 m/min

5. Quantity of rollers:ibr 18, corrugated 18

6. Main motor power:7.5 kw

7. Hydraulic station: 3.7 kw

8. Material of rollers: 45# with chromed

9. Shaft Material and diameter: ¢70 mm, material is 45# forge steel

10.Size of machine:9m*1.5m*1.5m

11.Weight :13 t

12. The body of machine: 350H

13.Tolerance: 10m+-1.5mm

14. Way Of Drive: Chain

15. Control system: PLC

16.Material of cutter blade: Cr12 mould steel with quenched treatment 58-62℃

17. Voltage: 380V/3Phase/50HZ(According to customer requirements)

|