|

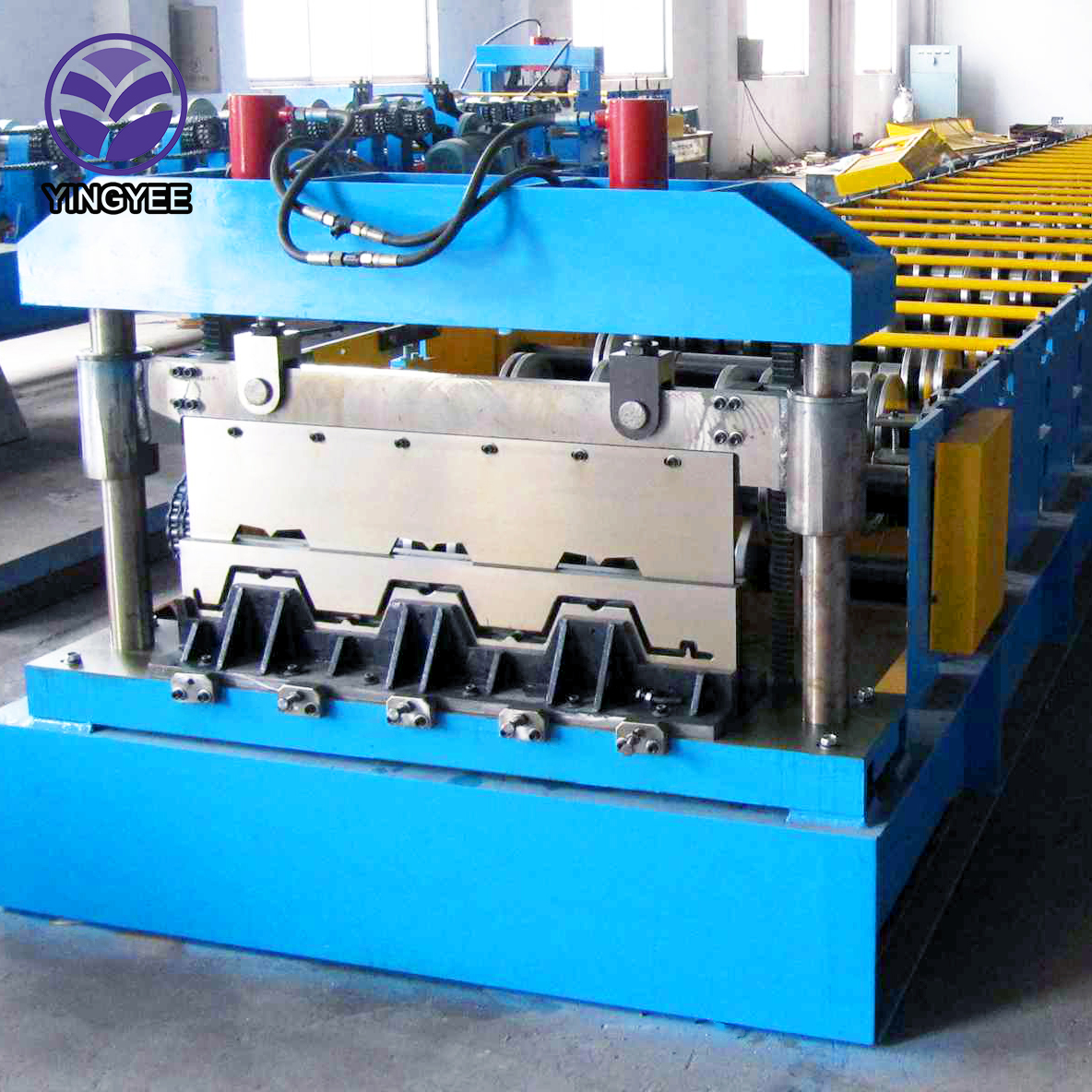

1.Matching material:PPGI/GI/Aluminium

2.Material thickness:0.2-0.8mm

3.Power:7.5kw

4.Forming speed:30m/min

5.The width of the plates:according to the drawings

6.input leveling equipment:adjustable as photos.

7.Roll stations:22

8.Shaft Material and diameter:materialis45#steel ¢80mm,

9.Tolerance:10m±1.5mm

10.Way of drive:chain with the motor

11.Controlling system:PLC

12.Voltage,Frequency,Phase: 380V, 50 Hz, 3Phase

13.Material of forming rollers:45#steel heat treatment and chromed 14Materialofcutterblade:Cr12mouldsteelwith quenched treatmentHRC58-62

15. Side plate:steel plate with Chromed.

|