In modern metal fabrication, achieving perfectly straight and accurately cut steel coils is essential for high-quality production. YingYee Machinery's straighten and cutting machine for steel coil delivers unmatched precision and efficiency, transforming raw coiled steel into ready-to-use flat sheets or strips with perfect dimensional accuracy. Our advanced machine combines state-of-the-art straightening technology with high-speed cutting capabilities, ensuring optimal material utilization and minimal waste for your manufacturing operations.

The straighten and cutting machine for steel coil features a robust construction designed for continuous industrial use, with adjustable settings to handle various material thicknesses and widths. Its intelligent control system automatically adjusts straightening pressure and cutting length, guaranteeing consistent results across different steel grades. Whether processing carbon steel, stainless steel, or aluminum coils, our machine maintains tight tolerances while operating at impressive production speeds. This makes it an indispensable asset for metalworking businesses looking to enhance their productivity and product quality.

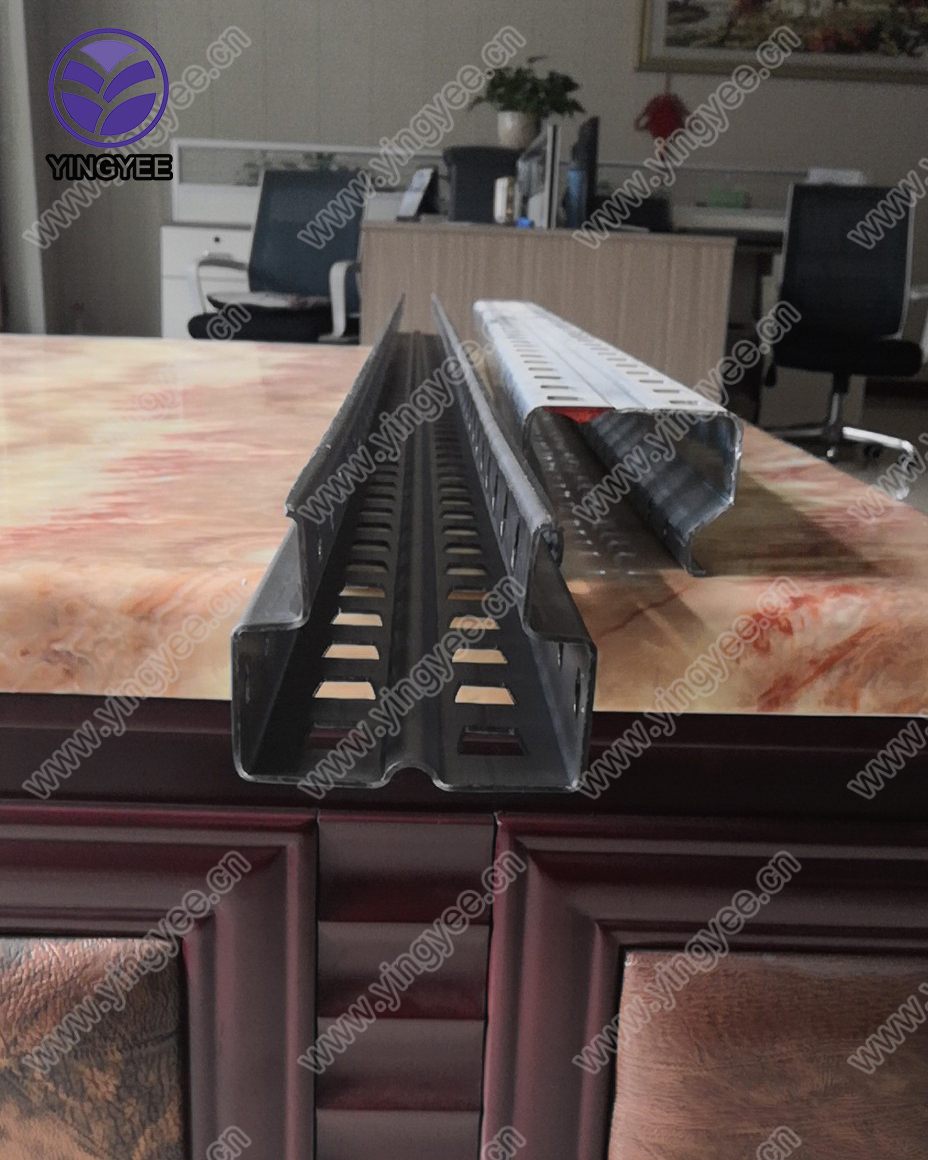

高精度调直切割机,可加工1.5mm、2mm、3mm不同厚度的镀锌板、冷轧板,有多种型号可供选择。

高品质的调直切割机,我们供应多种尺寸的多台机器,最大厚度可达 3 毫米,

仓储货架成型机为全自动生产线,可生产最大厚度为3mm的重型货架。

根据不同的厚度,速度在120-150m/min之间。

机器可加工1.5mm、2mm、3mm不同厚度的镀锌板、冷轧板,有多种型号可供选择。

调直切割机有多种尺寸可供选择,不同的厚度配有不同的调平部分滚轮。

机器可加工1.5mm、2mm、3mm不同厚度的镀锌板、冷轧板,有多种型号可供选择。

When precision matters in metal processing, YingYee Machinery's straighten and cutting machine for steel coil stands out as a superior choice. Unlike basic straightening equipment, our machine integrates advanced servo technology that precisely controls both the straightening rollers and cutting mechanism, eliminating common issues like edge waves or material distortion. The result is perfectly flat metal sheets with clean, burr-free edges ready for further fabrication or direct application.

A key advantage of our machine is its versatility. It effortlessly handles material thicknesses ranging from light-gauge metals to heavy steel plates, making it suitable for diverse industries from automotive parts manufacturing to construction material production. The quick-change tooling system allows for rapid adjustments between different material specifications, minimizing downtime during production changeovers. Additionally, the machine's energy-efficient design reduces power consumption while maintaining high output levels, providing significant cost savings over time.

YingYee Machinery has incorporated cutting-edge innovations into our straighten and cutting machine for steel coil to deliver exceptional performance in metal processing. The machine features a multi-roller straightening system with individually adjustable rollers that progressively eliminate coil memory and internal stresses from the material. This sophisticated approach ensures uniform flatness across the entire sheet, even when processing high-tensile strength steels or challenging alloys.

The cutting system represents another technological breakthrough, utilizing either high-precision hydraulic shears or flying cutters depending on application requirements. Our proprietary control algorithms synchronize the cutting action with material feed speed, enabling accurate cuts at full production velocity without stopping the line. For operations requiring specific lengths, the programmable length control system guarantees repeatable accuracy to within ±0.5mm, far surpassing industry standards.

Investing in YingYee Machinery's straighten and cutting machine for steel coil opens new opportunities for your metal processing business. The machine's high throughput capacity enables you to take on larger contracts and meet demanding delivery schedules, while its precision ensures you can service clients with the most stringent quality requirements. By bringing coil processing in-house, you gain better control over your supply chain and material costs, improving your overall competitiveness in the market.

The economic benefits extend beyond increased production capacity. Our machine's optimized design minimizes material waste at both the straightening and cutting stages, significantly improving your yield from expensive raw materials. The durable construction requires minimal maintenance, and our worldwide service network ensures prompt support when needed, maximizing your uptime and return on investment.