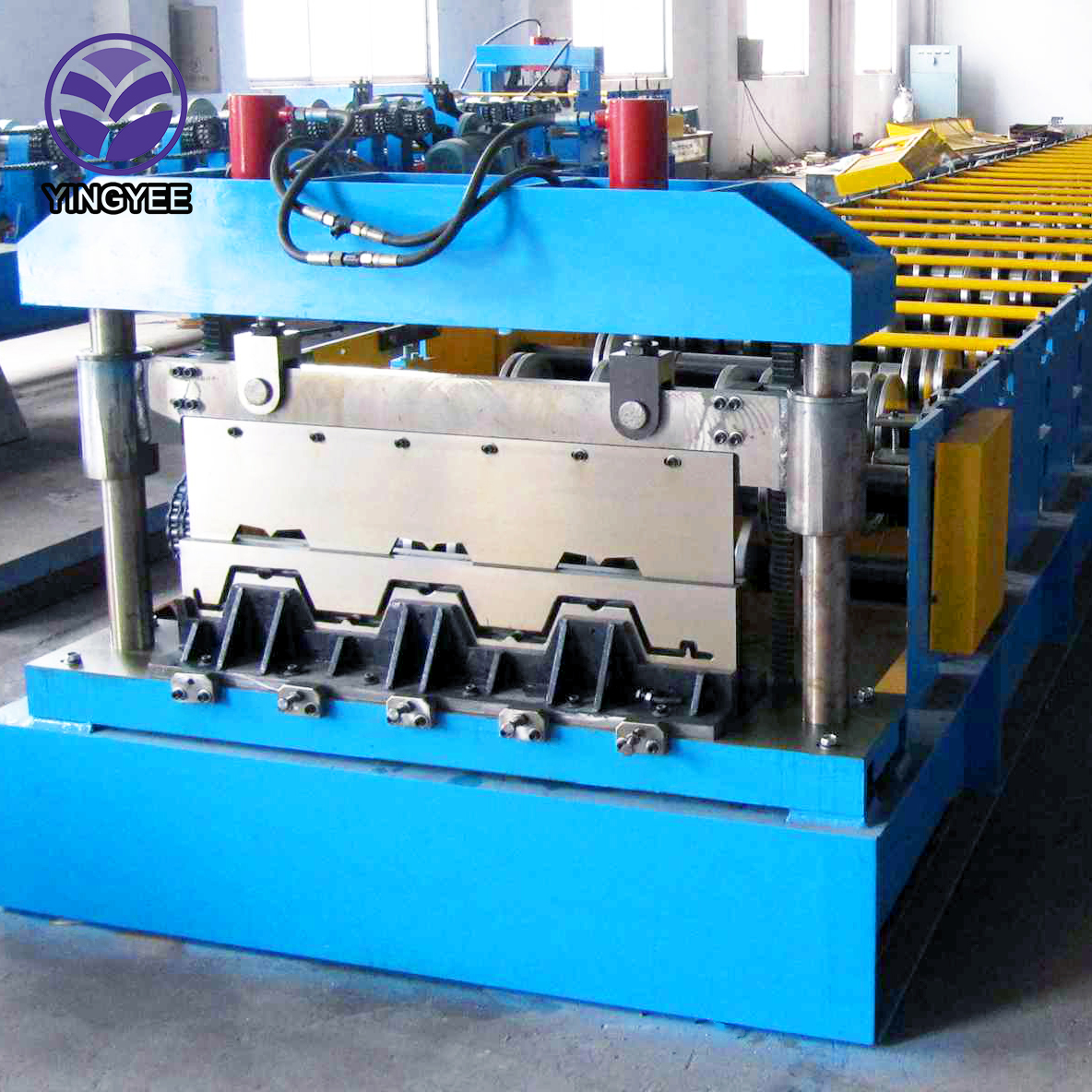

In the world of architectural water management, efficient and durable drainage systems are fundamental to building longevity. YingYee Machinery's Downpipe Roll Forming Machine represents the pinnacle of gutter manufacturing technology, engineered to produce high-precision round and square downpipes that combine flawless functionality with aesthetic appeal. This advanced system transforms metal coils into perfectly formed drainage components through a fully automated process that ensures consistency across every meter of production.

Our Downpipe Roll Forming Machine stands out with its multi-stage forming technology, capable of creating seamless pipes in diameters ranging from 75mm to 150mm with wall thicknesses up to 1.2mm. The servo-controlled forming system guarantees dimensional accuracy within ±0.3mm, while the intelligent welding unit (for seamed models) delivers strong, watertight joints. With production speeds reaching 15-25 meters per minute and the ability to process various materials including galvanized steel, aluminum, and pre-painted coils, this machine meets the diverse requirements of modern construction projects while maintaining exceptional energy efficiency.

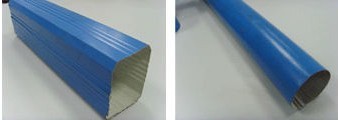

根据最终产品的形状,有圆管和方管可供选择。

圆形方形落水管滚压成型机精度高。根据最终产品的形状,可提供圆管和方管。

全自动机器,操作简单。根据最终产品的形状,可以选择圆管或方管。

地板甲板滚压成型机质量良好,厚度0.8-1.5毫米的成型效果良好。

根据最终产品的形状,有圆管、方管可供选择。

我们供应落水管滚压成型机、折弯机、滚压成型和折弯一体机以及排水沟滚压成型机。

根据最终产品形状,有圆管、方管可供选择,圆管直径(70mm、80m、90mm),方管直径(3"×4")。

For roofing specialists and building material manufacturers, our Downpipe Roll Forming Machine offers three game-changing advantages that elevate production standards. The adaptive forming pressure system automatically adjusts roller pressure based on material thickness variations, preventing deformation while ensuring perfect roundness or squareness.

A key innovation is the integrated punching unit that can add precise overflow holes and mounting brackets during the forming process, eliminating secondary operations. The automatic length control system guarantees exact downpipe segments with clean, burr-free ends ready for immediate installation. Most importantly, our machine's quick-change tooling system allows rapid switching between different pipe profiles and sizes - a critical advantage for manufacturers serving both residential and commercial markets.

The production process of our Downpipe Roll Forming Machine exemplifies precision engineering at its finest. It begins with laser-guided coil feeding, where material is precisely aligned before entering the leveling system. The multi-roller straightening unit removes all coil memory, ensuring perfectly flat material before forming.

As the strip progresses through 14-18 forming stations, it gradually transforms into the desired pipe shape with micrometer precision. The optional high-frequency welding unit creates continuous longitudinal seams with consistent penetration depth. Final processing includes servo-driven cutting that maintains ±1mm length accuracy and automatic stacking with protective separators to prevent surface damage. The entire process is monitored by vision inspection systems that verify dimensional accuracy and surface quality in real-time.

The products from our Downpipe Roll Forming Machine are essential components in diverse architectural scenarios:

Residential Roofing: Providing efficient water drainage for single-family homes and apartment complexes

Commercial Buildings: Handling high-volume runoff from large roof areas in shopping centers and office towers

Industrial Facilities: Offering durable solutions for factories and warehouses with aggressive weather conditions

Historical Restoration: Producing period-correct profiles for heritage building preservation