技术方案 的 定尺切割生产线

0.3-2*1300 cut to length line

1. Steel material: Galvanized Steel

2. Steel coil thickness: 0.3-2.0mm

3. Steel coil width: 500-1500mm

4. Max Steel coil weight: 10T

5. Steel coil I.D: 508-610mm

6. Steel coil O.D: ≤1500mm

7. line speed: 50-60m/min

8. Cutting speed:(as 1000*2000mm): 20-30 pieces/min

9. Shear length : 500-4000mm

10. Frame material: Q235

11. Voltage: 380V three-phase electricity 50Hz

12. Diagonal accuracy: ±1mm

13. Sizing accuracy: ±1mm

14. Total power: approx 70KW (Normal working power: 60KW)

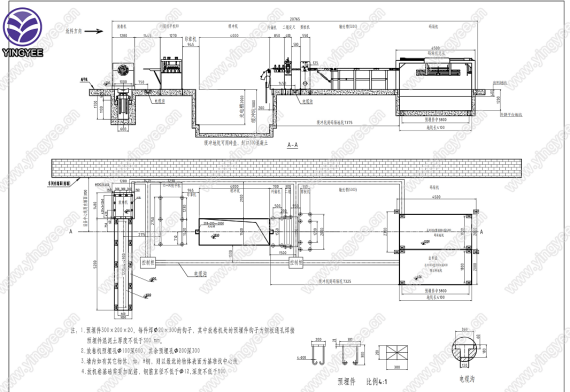

15. Unit area: Approx 23m*6m ( according to the using)

16. Unwinding direction: left to right facing the console

机器包括

1. Hydraulic single arm de-coiler with hydraulic feeding trolley

2. 15-axis dual-type precision leveling machine

3. Correction device (including trench tray)

4. Nine-roller servo sizing machine

5. Shearing machine

6. Electronic control system

7. Conveyor

8. Lifting palletizer

9. 4000mm in front of discharge platform

10. Hydraulic station

11. 风扇

定尺切割线溢流

液压单臂开卷机配液压送料小车

1. structure

该机为单头悬臂式液压胀缩放卷机,由主轴部分、传动部分组成。

(1) The main shaft part is the core part of the machine. Its four blocks are connected to the sliding sleeve through T-shaped slanting blocks and are simultaneously sleeved on the hollow spindle. The core is connected to the sliding sleeve. The fan blocks expand and contract at the same time. When the fan block shrinks, it is beneficial to roll up, and when the fan block is opened, the steel coil is tightened to complete the unwinding.

(2) The pressure roller is located behind the unwinder. The pressing arm is controlled by the oil cylinder to drive the cantilever to be pressed down and picked up. When feeding, the cantilever pressing roller is pressed to press the steel coil to prevent loosening and facilitate the feeding.(3) The transmission part is located outside the frame. The motor and reducer drive the main shaft of the unwinder through the gear to rotate, and it can also realize unwinding and rewinding.

2. Technical Parameters

(1) Steel coil width: 500mm-1500mm

(2) Steel coil weight: 10T

(3) Cylinder stroke: 600mm

运转电机:2.2kw

15轴双机精密整平机

1. Leveling rollers: 15

2. Leveling roller diameter: 120mm

3. Leveling roller material 45 # steel

4. Motor power: 22KW

5. The leveling effect is according to the first grade coil, except for scrap or secondary board.

6. Leveling roller material: 45 # steel.

7. After tempering, quenching and grinding, the surface hardness reaches HRC58-62, and the surface finish is Ra1.6mm.

8. The upper row of work rolls are lifted vertically by a motor drive.

9. Roller bearings are used for the work roll bearings, which have a high bearing capacity and a long service life.

主力系统:采用一台电动机集中驱动,经减速器传动箱万向节传动。

坑

1. It uses the 2 groups of magic eyes to control the speed buffer between decoiler and slitting machines.

2. Magic eye is controlled by PLC.

3. Function: it is used to eliminate the different speed and make the plates which in wrong rail to back the right way. At first, it is used the oil cylinder to lifting the supporting and transition plates to make the head pass. When working, the transition and supporting plates lift down, the steel plates will be stored in the pit.

Correction device with Nine-roller servo sizing machine

纠偏装置:

1. Guided by vertical guide rollers. Adjust the distance between the two guide rollers manually.

2. Minimum guide width 500mm

Nine-roller servo sizing machine specifications

1. Feeding rollers: 9

2. Leveling roller diameter:120mm

3. Fixed-length roller diameter: 160mm

4. Roller material 45 # steel

伺服电机:11kw

气动剪板机

气动剪板机:

主要由左、右支架、连杆、上下刀架、工作台、驱动电机等组成。

(1) Maximum cutting thickness: 3mm

(2) Shearing width: 1600mm

(3) Motor power: 11KW

传送带:

传送带:

1. Belt length :7500mm

2. Width: 1450mm

电机2.2kw(变频调速)

升降码垛机

Lifting palletizer (Note: 4000mm lifting position, source of gas)

1. The blanking machine mainly carries out the blanking of the sheet, which is composed of a horizontally moving rack body and a vertical baffle.

2. The horizontal moving frame is manually adjusted according to different board widths, and the vertical baffle is adjusted according to different board lengths.

3. The stacking machine is mainly composed of stacking cylinder walking rollers and motors. Its function is to neatly stack the blanked plates.

主要技术参数

(1) Height of blanking rack: 2100mm

(2) Total length of blanking rack: 4300mm

(3) Total width: 2300mm

承重架:10000kg

更多参考照片:

我们的服务:

机器装车照片:

纵剪线又称分条生产线,是将金属卷料开卷、分切、收卷成所需宽度的条状,速度很快,生产能力高,与低速机相比,产量与能耗同时具有明显优势,采用直流主电机,寿命长,运行稳定可靠。

适用于冷轧、热轧碳钢、硅钢、不锈钢及表面涂层后的各种金属材料的加工。