|

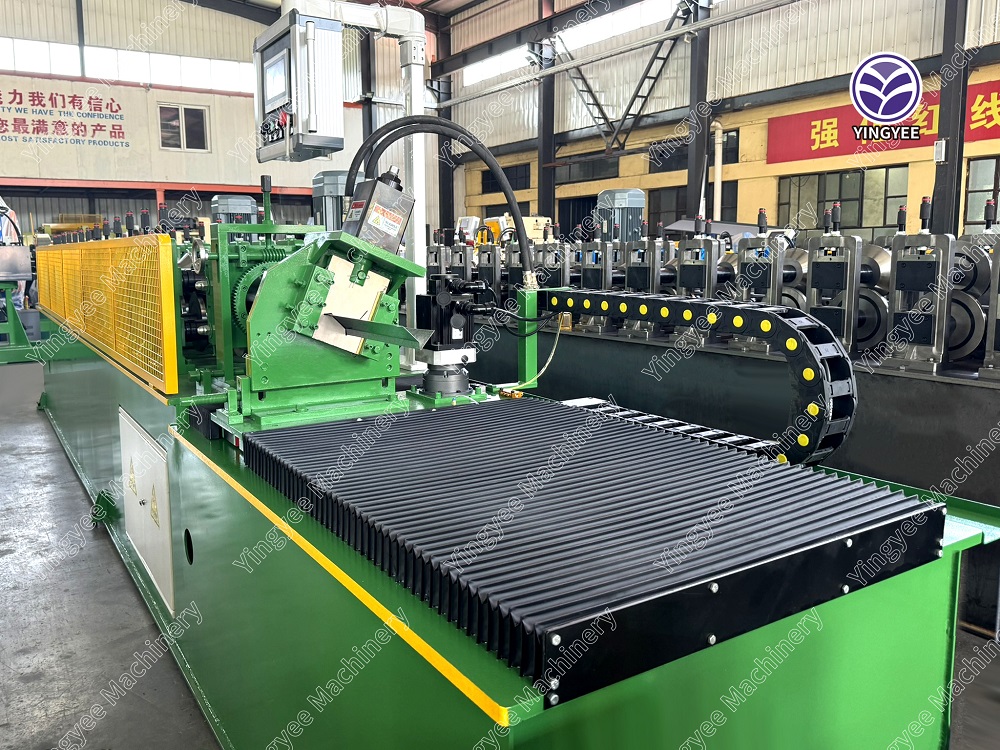

1.Matching lintho tse bonahalang: ppgi

2. Botenya ba lintho tse bonahalang: 0.3 - 0.8mm

3. Matla: 5.5 kW

4. Lebelo la ho bōpa: 15M / min

5. Bophara ba poleiti: ho latela setšoantšo

6. Input Leveling Device: e ka fetoloa joalokaha ho bontšitsoe setšoantšong.

7. Seteishene sa lirolara: 13

8. Shaft thepa le bophara: 45 # tšepe¢75mm,

9. Tolerancia: 10 m ± 1,5 mm

10. Mokhoa oa ho khanna: ho khanna ketane

11. Tsamaiso ea taolo: PLC

12. Motlakase: 380v, 50hz, mekhahlelo e meraro

13. Molding rolara lintho tse bonahalang: 45 # tšepe e tšoaroang mocheso, chrome plated

14. Letlapa la mahlakoreng: poleiti ea tšepe ea chrome.

|