|

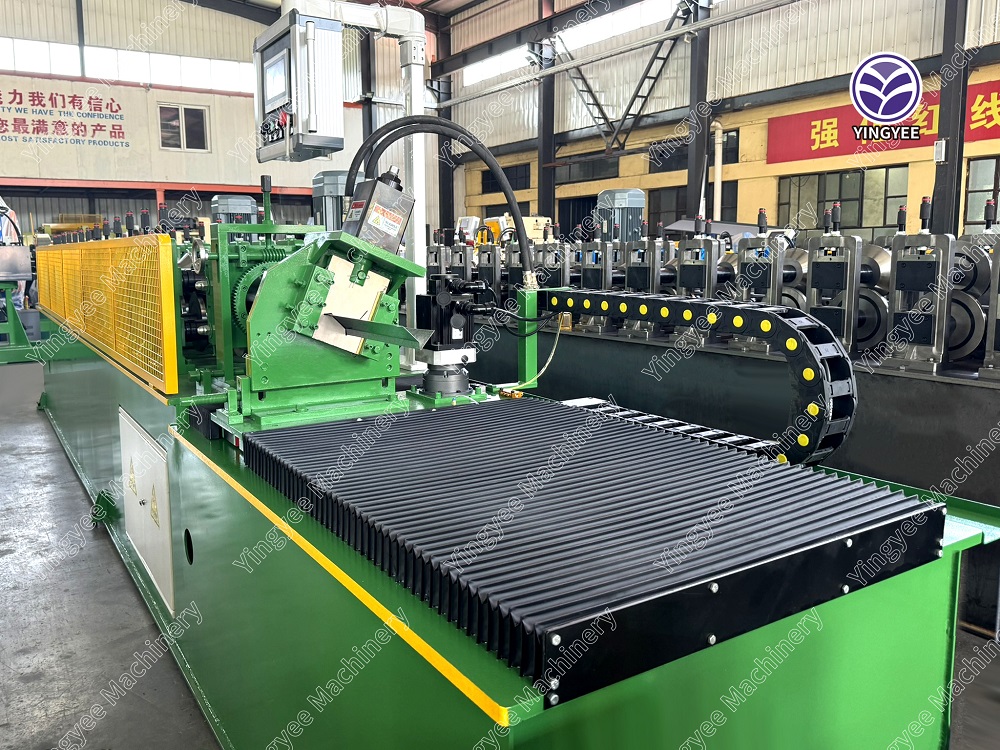

1.Matching khoom: ppgi

2. Khoom thickness: 0.3 - 0.8mm

3. Lub zog: 5.5 kW

4. Moulding ceev: 15M / min

5. Dav ntawm phaj: raws li kev kos duab

6. Input Leveling Device: adjustable raws li qhia hauv daim duab.

7. Roller chaw nres tsheb: 13

8. Cov khoom siv thiab txoj kab uas hla: 45 # steel¢75mm,

9. Tolerancia: 10 m ± 1,5 hli

10. Tsav hom: saw tsav

11. Tswj qhov system: PLC

12. Voltage: 380v, 50hz, peb theem

13. Moulding cov khoom siv: 45 # cov hlau kho cua sov, chrome plated

14. Sab phaj: chrome steel phaj.

|