The W beam guard rails roll forming machine is an engineering marvel that caters to the needs of the modern infrastructure landscape. Designed with precision and expertise, this machine is pivotal in manufacturing durable guard rails, providing safety and security across highways and roads globally. Its mechanism, far removed from traditional manufacturing techniques, embodies a synthesis of innovation and engineering excellence that countless industries have come to rely on.

Having been involved in the field for over a decade, I can attest to the significant impact that utilizing cutting-edge roll forming machines can have on production efficiency and product quality. The W beam guard rails roll forming machine stands out due to its rigorous design and high operational standards that ensure reliability and versatility.

The expertise embedded within these machines emphasizes several core components high-quality rollers, an advanced control system, and robust steel frame construction. Each part plays a pivotal role in ensuring the machine meets and exceeds industry standards. The high-quality rollers, for example, are crafted from hardened steel, ensuring longevity and precise shaping capabilities of the guard rails. This precision is crucial, as guard rails must meet specific dimensional tolerances to be effectively utilized on roadways.

Technical authority is further established through the machine's programmable logic controller (PLC) systems, which offer unsurpassed control over the roll forming process. This intelligent system allows for precise adjustments, delivering consistent product quality while minimizing errors. The inclusion of automated features like the PLC not only enhances productivity but also allows for more complex design capabilities, meeting diverse project requirements.

Trustworthiness in the manufacturing process is another hallmark of the W beam guard rails roll forming machine. Reputable manufacturers source premium materials and adhere to stringent quality control procedures throughout the manufacturing and assembly stages. Certifications from international safety and quality assurance bodies often accompany these machines, reinforcing their dependability and safety.

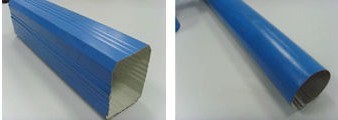

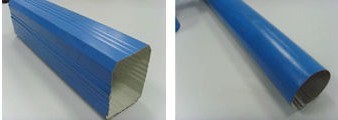

w beam guard rails roll forming machine

Moreover, deploying a W beam guard rails roll forming machine substantially reduces material waste and operational costs compared to other manufacturing processes. The machine's ability to perform continuous bending operations ensures material efficiency, translating to cost savings that can be pivotal for large-scale infrastructure projects. Businesses seeking to optimize their manufacturing processes without compromising on quality often find these machines to be an indispensable asset.

True experience comes from understanding the intricacies of operating and maintaining these machines. Regular maintenance is crucial to ensure longevity and optimal performance. By keeping components such as the hydraulic systems and rollers in prime condition, operators can significantly extend the machine's lifespan. This proactive maintenance approach not only enhances production but also safeguards the significant investment made in procuring advanced machinery.

The authoritative knowledge surrounding W beam guard rails roll forming machines is further bolstered by real-world testimonials from industry professionals. They've highlighted the substantial improvements in production efficacy and product quality since integrating these machines into their operations. Reports indicate a marked increase in installation projects' success rate, due to the consistent output and highly reliable construction of rails produced by these machines.

Ultimately, the W beam guard rails roll forming machine sets a benchmark for innovation, reliability, and efficiency in the field of guard rail manufacturing. Its emergence is indicative of the broader shift towards automated, intelligent manufacturing solutions poised to meet the infrastructural demands of the future. For businesses and industries navigating the complexities of modern infrastructure development, this machine represents not merely a tool, but a critical partner in achieving precision, safety, and efficiency in guard rail production.

The evolution of roll forming technology and the commitment to continuous improvement ensure these machines will remain at the forefront of manufacturing, satisfying both current and future needs with unparalleled effectiveness.