In the ever-evolving construction industry, the demand for efficiency, precision, and durability has never been higher. An integral component in achieving these objectives is the utilization of advanced machinery like the automatic steel frame sale stud and track C channel drywall main furring wall angle roll forming machine. This sophisticated equipment has transformed how construction projects are executed, offering significant improvements in both speed and quality.

When discussing the realm of construction machinery, it is essential to focus on the technical prowess and user experience provided by such machines. The automatic steel frame roll forming machines have revolutionized framing processes by facilitating seamless production of steel studs and tracks. These machines are meticulously designed to produce accurate and consistent profiles, essential in maintaining uniformity in construction projects.

The backbone of any strong construction is its frame, and that's where this roll forming machine excels. Leveraging state-of-the-art technology, these machines transform steel coils into precise structures by employing a continuous bending operation. This automated process ensures that construction teams can consistently produce high-quality components with minimized human error. The result is a significant reduction in operational costs and project timelines, making these machines indispensable in modern construction settings.

Professional expertise in the operation and maintenance of these machines is crucial. Operators must be well-versed with machine settings, maintenance protocols, and operational guidelines to ensure smooth and efficient operations. This expertise not only assures the longevity of the machinery but also guarantees that the produced steel frames meet stringent industry standards. By upholding such standards, construction companies can assure clients of the durability and structural integrity of their buildings.

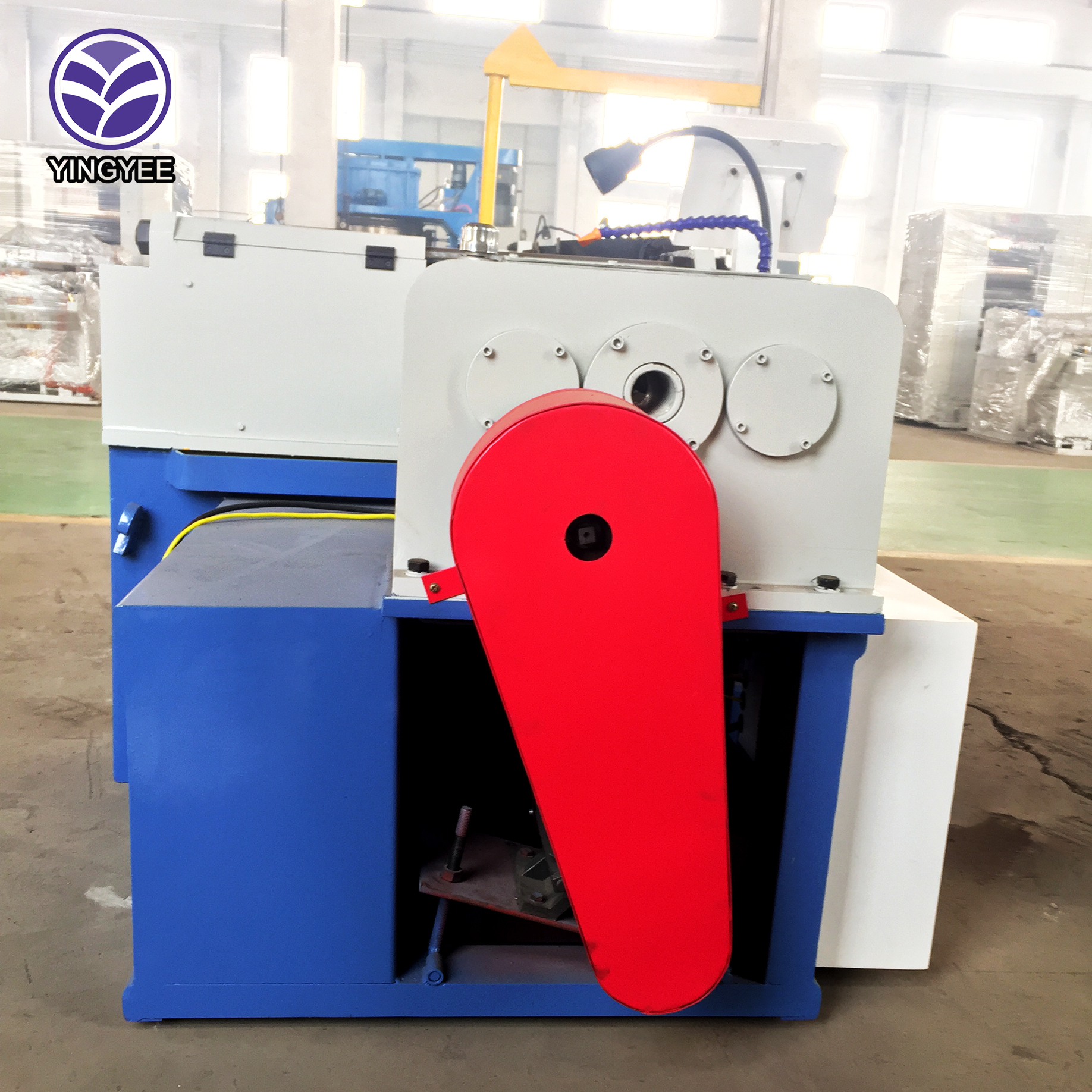

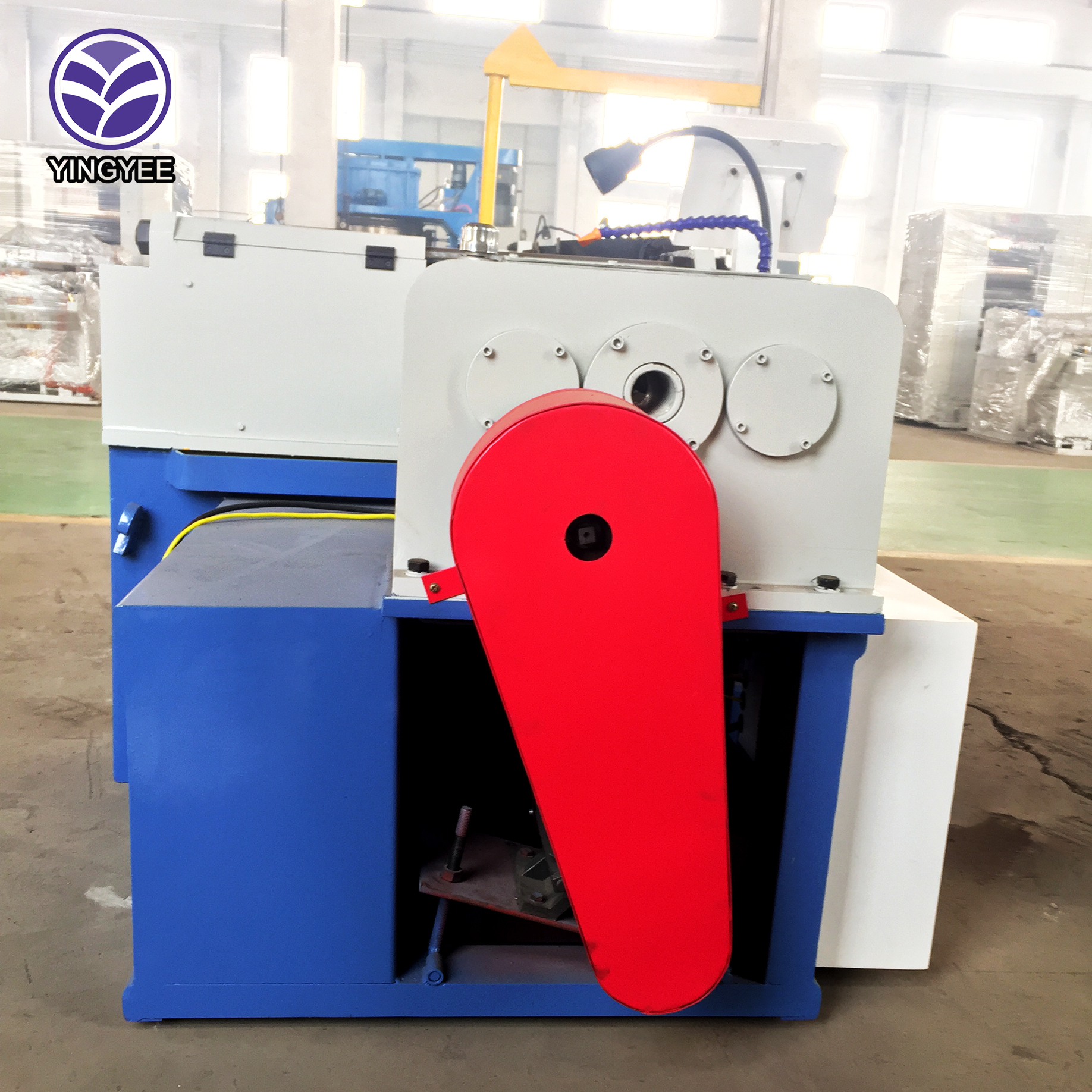

automatic steel frame sale stud and track c channel drywall main furring wall angle roll forming machine

The authority of these machines in the industry is undisputed. They incorporate cutting-edge technology that supports a diverse array of construction requirements, from simple residential projects to complex commercial infrastructures. The reputation of these machines is bolstered by endorsements from leading industry professionals, who acknowledge the impact such equipment has on improving construction accuracy and efficiency.

Trustworthiness is paramount when investing in construction machinery. Manufacturers of the automatic steel frame roll forming machines prioritize quality assurance through rigorous testing and certification processes. Each machine undergoes comprehensive evaluations to certify that it meets all operational safety and performance benchmarks. These stringent quality control measures ensure that construction firms can rely on these machines to perform optimally on-site, reinforcing the safety and reliability essential for long-term use.

From provide high-capacity throughput to customization flexibility, these machines support a wide array of construction needs. Construction companies dedicated to staying ahead of the competition while adhering to eco-friendly practices also value these machines for their energy efficiency and reduced material waste. The automatic nature of these machines means that they produce less scrap material compared to traditional methods, contributing to more sustainable construction practices.

In conclusion,

the automatic steel frame sale stud and track C channel drywall main furring wall angle roll forming machine stands as a testament to the advances in construction technology. Its contribution to the industry in terms of enhancing efficiency, ensuring high-quality output, and reducing costs is unparalleled. For any construction company aiming to boost its operational capabilities, investing in this technology not only provides a competitive edge but also aligns with modern sustainability goals. By embracing such innovations, the industry moves forward, setting new standards for excellence in construction.