The Versatility of Quick Changeable C/Z Purlin Roll Forming Machines

In the ever-evolving construction industry, efficient and adaptable machinery plays a pivotal role in meeting diverse structural needs. Among these, the quick changeable C/Z purlin roll forming machine stands out as a revolutionary advancement. This technology is designed to produce both C and Z shaped purlins swiftly, catering to the varying requirements of modern construction projects.

Understanding C/Z Purlins

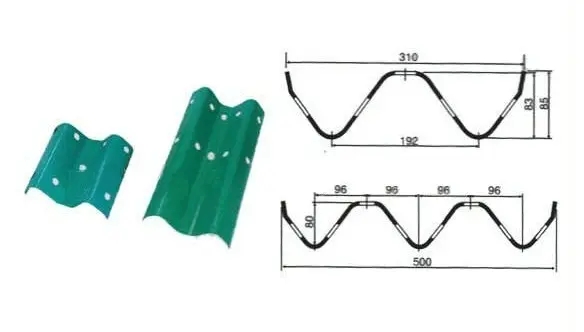

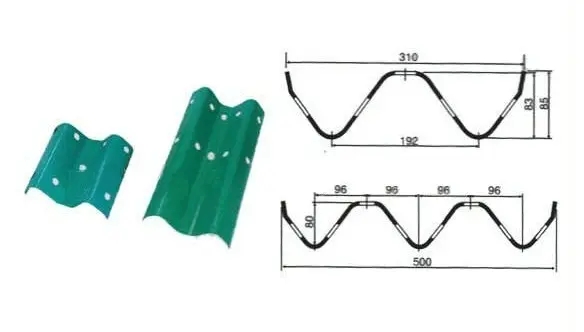

Purlins are horizontal structural elements used in buildings to support the roof. They are critical for the stability and strength of the structure, facilitating the attachment of roofing sheets and providing support for the overall weight of the roof. C and Z purlins are named for their distinctive shapes, which also determine their load-bearing capabilities and suitability for different applications.

C purlins are typically utilized in applications requiring a flat surface, while Z purlins allow for a more interlocking installation, enhancing structural integrity. The demand for these components is high, driven by the increase in commercial and industrial construction activities worldwide.

What is a Quick Changeable Roll Forming Machine?

A quick changeable roll forming machine is designed to switch between profiles—C and Z—in a matter of minutes. This capability is crucial for manufacturers who need to produce varying types of purlins rapidly to respond to market demands or specific project requirements. The machine uses a series of rollers to shape steel sheets into the desired profile, maintaining precision and uniformity in each product.

Benefits of Quick Changeable C/Z Purlin Roll Forming Machines

quick changeable c/z purlin roll forming machine

1. Efficiency and Productivity Traditional roll forming machines often require extensive downtime for changeovers, impacting productivity. Quick changeable machines minimize this downtime, allowing manufacturers to maximize output without compromising on quality. This efficiency is especially important in competitive markets where time is of the essence.

2. Cost-Effectiveness By streamlining the production process and reducing lead times, these machines help lower labor and operational costs. Additionally, the dual capability of producing both C and Z purlins in one machine means companies can invest in fewer machines, optimizing their capital expenditure.

3. Flexibility The ability to switch between different purlin shapes means manufacturers can diversify their product offerings. This flexibility enables businesses to tap into various market segments, adapting to changing customer needs without the need for additional equipment.

4. Quality Control Modern quick changeable roll forming machines are equipped with advanced technology, including computer numerical control (CNC) systems. These innovations ensure precise measurements and consistent quality, significantly reducing waste and rework.

5. Space-Saving Design Manufacturing facilities often have limited space. By consolidating the production of different purlin types into one machine, businesses can optimize their factory layout and reduce the footprint needed for equipment.

Conclusion

The quick changeable C/Z purlin roll forming machine represents a significant advancement in manufacturing technology within the construction sector. By enhancing efficiency, flexibility, and cost-effectiveness, these machines enable manufacturers to meet the rising demands of the construction market. As the industry continues to evolve, investing in such innovative solutions will be essential for any company looking to maintain a competitive edge and ensure they can provide high-quality, adaptable structural components to their clients. Embracing this technology is a step towards a more productive and responsive manufacturing future.