Understanding U Purlin Roll Forming Machines A Comprehensive Guide

In modern construction, the demand for efficient and cost-effective structural components has led to the widespread use of U purlins. These structural members are essential in supporting roofs and walls, providing critical load-bearing capacity while maintaining lightweight qualities. The production of U purlins is predominantly achieved through roll forming technology, which utilizes a dedicated machine known as a U purlin roll forming machine. This article aims to provide an in-depth look at U purlin roll forming machines, their working principles, and their applications.

What is a U Purlin Roll Forming Machine?

A U purlin roll forming machine is an industrial device designed to produce U-shaped purlins from flat metal sheets. The machine operates through a series of roller stations that progressively shape the metal as it passes through. The rollers are meticulously designed to gradually bend the material into the desired U shape, creating uniform profiles that are crucial for structural applications. The machines can handle various metal thicknesses and materials, including galvanized steel, mild steel, and more.

Key Components of a U Purlin Roll Forming Machine

1. Uncoiler This component holds the raw metal coil and feeds it into the machine. It ensures a smooth and consistent feed rate, which is vital for maintaining production efficiency.

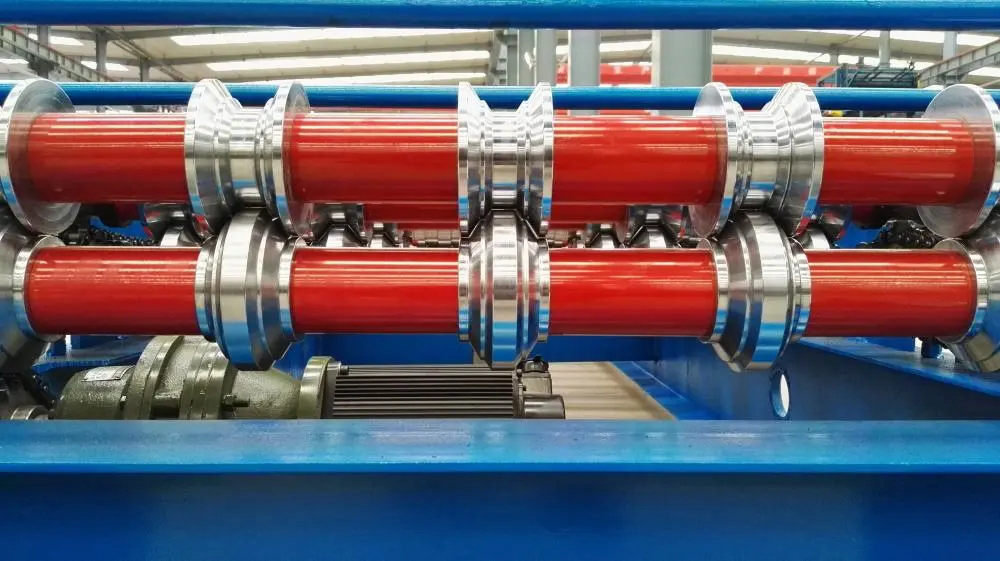

2. Roll Forming Stations The heart of the machine consists of multiple roller stations arranged in sequence. Each station performs a specific bending or shaping operation to create the U shape.

3. Cutting Device Once the U purlin reaches the desired length, it is cut to size by a cutting device, which can be hydraulic or mechanical, depending on the machine design.

4. Control System Modern U purlin roll forming machines are equipped with advanced control systems that allow operators to input specifications, monitor production outputs, and make real-time adjustments.

Working Principle

The operation of a U purlin roll forming machine is relatively straightforward. It begins with the uncoiling of the metal sheet, which is then fed into the first roller station. As the material passes through each of the subsequent roller stations, it is progressively shaped into the U profile. The rollers apply uniform pressure, and the material is bent without any significant changes to its thickness. Once the desired length is achieved, the cutting device activates to section off the U purlin, which is then collected for distribution.

Advantages of Using U Purlin Roll Forming Machines

1. High Production Efficiency These machines are designed for continuous operation, which allows manufacturers to produce large quantities of U purlins quickly and efficiently.

2. Consistency and Precision The automated nature of the roll forming process ensures uniformity in product dimensions and shapes, making every U purlin identical in quality and performance.

3. Material Saving Roll forming minimizes waste by ensuring that material is used efficiently during the shaping process.

4. Versatility U purlin roll forming machines can be adjusted to produce various lengths, widths, and thicknesses, enabling manufacturers to cater to diverse customer needs.

5. Durability The machines are built robustly to withstand the rigors of industrial production, ensuring a long service life and minimal maintenance requirements.

Applications of U Purlins

U purlins are widely used in various construction projects, including warehouses, garages, industrial buildings, and agricultural structures. They serve as vital support components for roofing and siding systems, contributing to the overall stability and durability of the structure.

Conclusion

U purlin roll forming machines are an essential asset in the construction industry, offering efficient, precise, and standardized production of U purlins. As demand for lightweight yet strong structural components continues to rise, understanding the capabilities of these machines becomes crucial for manufacturers aiming to remain competitive in the ever-evolving construction market. With advancements in technology and engineering, the future of U purlin roll forming machines looks promising, ensuring they will remain at the forefront of construction innovation.