Tube Rolling Machine for Sale A Comprehensive Guide

The manufacturing industry has advanced significantly over the years, with machines and equipment becoming more efficient in producing high-quality products. Among these machines, tube rolling machines have emerged as essential tools for metalworking and fabrication. For those in the market for a tube rolling machine for sale, understanding the various types, features, and benefits is crucial for making an informed purchase.

What is a Tube Rolling Machine?

A tube rolling machine is a versatile piece of equipment used to shape and curve metal tubes and pipes through a process known as rolling. This machine can achieve various bends and radii, making it an indispensable tool for industries such as automotive, aerospace, construction, and manufacturing. Tube rolling machines can handle a wide range of materials, including steel, aluminum, and brass, ensuring that they meet the demands of different applications.

Types of Tube Rolling Machines

When considering tube rolling machines for sale, it’s essential to understand the different types available in the market

1. Three-Roll Bending Machines These machines use three rolls to bend the tube, providing precise control and consistent results. They are ideal for producing curves with a specific radius.

2. Four-Roll Bending Machines Featuring an additional roll, four-roll machines offer greater precision and flexibility, making them suitable for complex designs and larger pipes.

3. Mandrel Bending Machines These machines are equipped with a mandrel that helps maintain the integrity of the tube’s inner diameter during the bending process. They are particularly useful for tight bends and high-stress applications.

4. Automated Tube Rolling Machines For high-volume production, automated machines offer speed and efficiency. They can be programmed for various bending processes, reducing manual labor and increasing overall productivity.

Key Features to Look For

When shopping for a tube rolling machine, consider the following features

- Material Compatibility Ensure the machine can handle the materials you intend to work with, as different machines have varying capabilities.

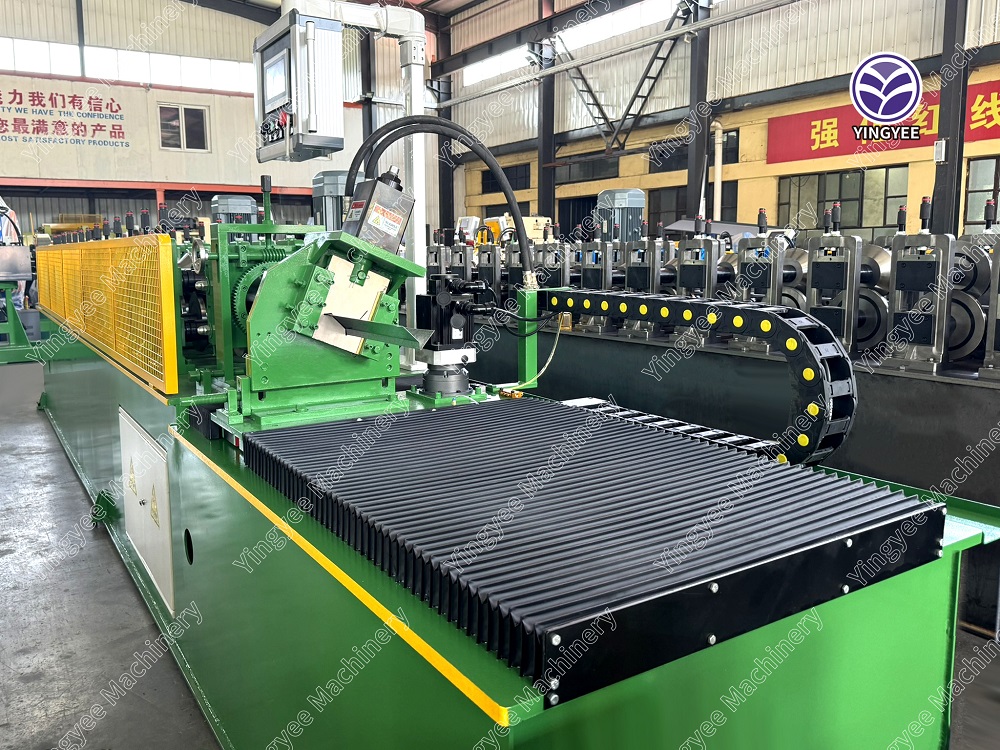

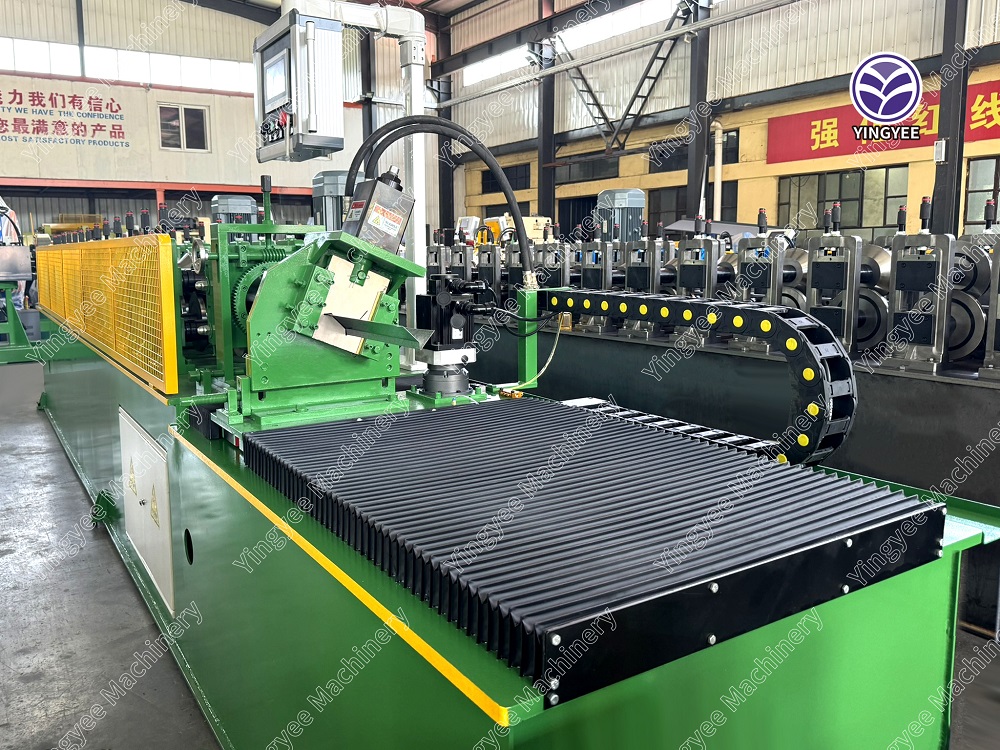

tube rolling machine for sale

- Bending Capacity Assess the maximum diameter and wall thickness the machine can accommodate, which is crucial for meeting your project requirements.

- Control System Opt for a user-friendly control interface, as this will enhance the ease of operation and reduce the learning curve.

- Build Quality A robust construction ensures durability and reliability, enabling the machine to withstand the rigors of continuous use.

- Safety Features Look for machines equipped with safety mechanisms to protect operators and prevent accidents during operation.

Benefits of Investing in a Tube Rolling Machine

Investing in a tube rolling machine offers several benefits

- Increased Efficiency These machines automate the bending process, significantly speeding up production compared to manual methods.

- Improved Accuracy Tube rolling machines provide consistent bends and shapes, reducing material waste and ensuring high-quality outputs.

- Versatility With the ability to work with various materials and designs, these machines offer flexibility to meet diverse project requirements.

- Cost-Effectiveness Over time, the efficiency and precision of a tube rolling machine can lead to significant savings in labor and material costs.

Conclusion

Purchasing a tube rolling machine can be a game-changer for businesses involved in metalworking and fabrication. With a variety of options available for sale, buyers should carefully consider their specific needs before making a decision. By understanding the different types, key features, and benefits, prospective buyers can find the perfect tube rolling machine that will enhance their productivity and efficiency in the long run. Investing in the right machine not only streamlines production processes but also ensures the delivery of high-quality products that meet industry standards.