The world of construction and building materials is ever-evolving, with innovations continuously emerging to enhance functionality and efficiency. Among these innovations, the technology of stud and track keel roll forming holds significant importance. This process has not only transformed the production of construction components but also streamlined the performance of installations across different types of buildings.

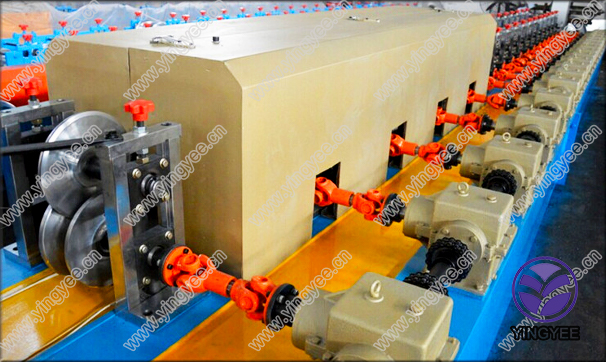

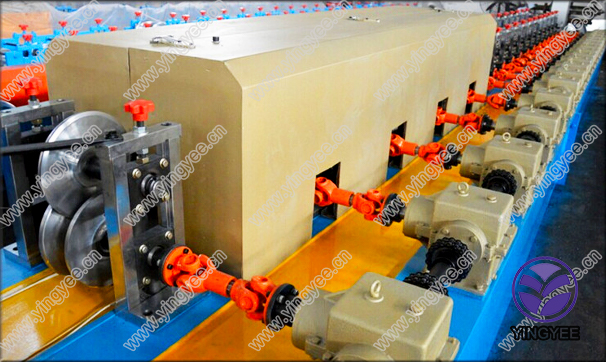

Stud and track keel roll forming is a specialized process that involves the continuous bending of a long strip of metal through a series of rolls to create high-precision components. These components, namely metal studs and tracks, are universally acknowledged as vital elements in modern construction, particularly in the framing of non-load bearing walls and partitions.

From an experiential standpoint, employing stud and track keel roll forming in manufacturing significantly benefits construction projects. This method generates components that are uniform in dimension and quality, thus ensuring a seamless fit during assembly. Contractors who have integrated these rolled components into their projects report a marked decrease in installation times, translating to faster project completion rates. Additionally, the customization capability of roll forming systems allows for adjustments in design specifications, which means they can be tailored to meet specific architectural needs.

In terms of expertise, professionals in the field rely on advanced roll forming machines that utilize computer-aided designs (CAD) to dictate precise measurements and angles. This precision not only optimizes material usage but also reduces waste, aligning with sustainable construction practices. Moreover, specialists who operate these machines often undergo rigorous training, ensuring they possess the technical knowledge to maintain operational efficiency and manage troubleshooting effectively.

stud and track keel roll forming

The authoritativeness of the stud and track keel roll forming process is reinforced by compliance with international construction standards. The precision and reliability of roll-formed products ensure they meet safety regulations and structural requirements, making them trusted choices for architects and builders. Globally recognized construction firms often specify roll-formed components in their procurement, underlining their preference for materials that exemplify superior quality and dependability.

Trustworthiness, as an essential attribute, is deeply embedded in the production of roll-formed studs and tracks. Manufacturers implement stringent quality control measures to uphold the integrity of their products. Through rigorous testing and certification processes, each batch of roll-formed components is verified for strength, durability, and consistency. This assures end-users of the reliability and long service life of the components, fostering trust in both the product and the manufacturer.

In conclusion, the stud and track keel roll forming process is a testament to modern engineering and manufacturing capabilities. Its integration into the construction industry brings enhanced efficiency, quality, and innovation. By embodying principles of expertise, authority, and trust, this technology not only supports contemporary building projects but also paves the way for future advancements in construction methodologies.