Exploring the world of advanced metal forming machinery, the single Z Purlin forming machine stands out as a remarkable innovation. This machine is pivotal in the construction and manufacturing industries, offering precision, efficiency, and adaptability.

Single Z Purlin forming machines are designed to shape metal sheets into Z-shaped purlins, crucial components for structural frameworks in buildings. Their significance lies in their capacity to produce strong, durable purlins that support various architectures, from homes to commercial complexes.

Experience in utilizing a single Z Purlin forming machine reveals its transformative impact on production lines. Operators and manufacturers benefit from its automated features that reduce manual intervention, enhancing operational efficiency. The machine's user-friendly interface simplifies processes, allowing even those new to metal forming to achieve optimal results with minimal training.

Expertise in this domain underscores the technical precision these machines offer. Equipped with advanced programmable logic controllers (PLCs), they enable precise control over the forming process. Users can adjust parameters such as length, width, and thickness, ensuring that the purlins meet exact specifications. This flexibility is crucial in accommodating diverse project requirements and adhering to stringent quality standards.

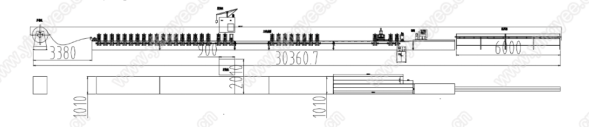

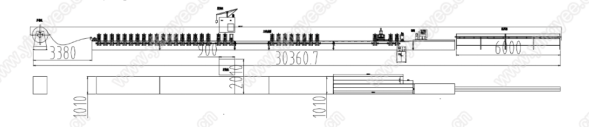

single z purlin forming machine

The authoritativeness of single Z Purlin forming machines is evident in their widespread adoption across industries. Leading manufacturers and construction companies rely on these machines to meet large-scale production demands while maintaining quality. Their robust construction and cutting-edge technology make them a trusted choice for projects that mandate consistency and reliability.

Trustworthiness is a critical element that sets these machines apart. By employing high-grade materials and rigorous quality checks, manufacturers guarantee their longevity and performance. The machines are engineered to minimize maintenance needs and downtime, offering a seamless operation over extended periods. Additionally, compliance with international safety and quality standards assures users of their investment's security.

In the competitive landscape of metal forming, investing in a single Z Purlin forming machine is a strategic move towards modernization and efficiency. As technology continues to evolve, these machines are poised to integrate with digital systems, offering real-time monitoring and analytics to further optimize production processes.

The single Z Purlin forming machine is more than a piece of equipment—it's a comprehensive solution that enhances operational capabilities, fosters innovation, and propels businesses towards sustainable growth. For those looking to elevate their production line, this machine represents the pinnacle of engineering excellence and practical utility.