Advancements in construction technology have transformed the way we approach building and design. The innovation of roll forming machinery has become a pivotal aspect of modern construction, particularly in the creation of various metal framing components essential for drywall and track systems. Understanding the capabilities and advantages of stud and track/drywall/c channel/main channel/wall angle frame roll forming machinery is crucial for construction professionals aiming to enhance efficiency and reliability in their projects.

A roll forming machine is a highly specialized piece of equipment that shapes metal coils into desired profiles. These machines are integral to producing the metal frameworks used extensively in construction. The expertise involved in operating roll forming machinery relies on understanding its ability to handle different materials such as galvanized steel, aluminum, and various alloys while maintaining precise dimensional accuracy. Such precision ensures seamless installation and structural integrity in drywall and ceiling systems.

One of the most significant strengths of roll forming machinery lies in its customization capabilities. Each construction project comes with specific demands, and the ability to produce custom profiles for studs, tracks, c channels, and wall angles allows builders to tailor their materials to fit exact architectural specifications. This not only improves the construction process but also minimizes waste, enhancing sustainability—a key concern in today's environmentally-conscious building industry.

Operational efficiency is another remarkable advantage of these machines. They are designed to function at high speeds, increasing production rates without sacrificing quality. For industry experts, leveraging this efficiency can significantly reduce the lead time from design to construction, allowing projects to stay on schedule and within budget. This builds trust between contractors and clients who rely on timely delivery to meet economic projections and project timelines.

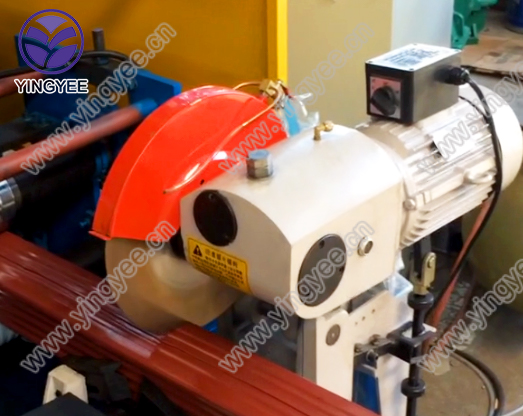

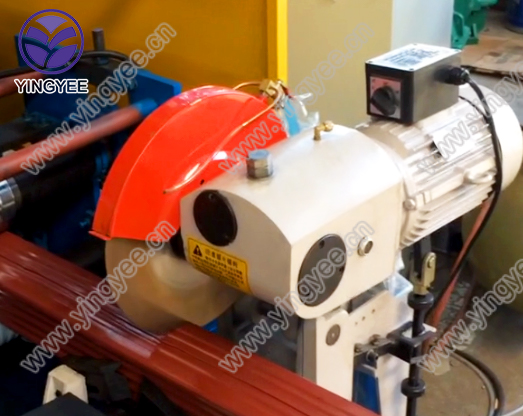

stud and track/drywall/c channel/main channel/wall angle frame roll forming machinery

In addition to their functional benefits, these machines represent a high standard of authoritativeness in construction. Manufacturers of roll forming machinery undergo rigorous testing and quality control to ensure their products meet international building codes and standards. Professionals investing in high-quality machinery can assure clients and regulatory bodies that their construction practices adhere to best industry practices, further reinforcing reliability and trust.

Upkeep and maintenance of roll forming machines are essential facets of their operation. Regular technical training for operators ensures that the machinery functions at optimal levels, prolonging its lifespan and preventing costly breakdowns. A trustworthy manufacturer provides ongoing support and detailed guidance on servicing, a critical aspect that construction managers should prioritize to maintain uninterrupted production.

The rise of roll forming machinery in construction is indicative of a broader trend towards automation and precision engineering. Industry veterans recognize the value in integrating these advanced systems into their workflow to achieve superior results. This technology exemplifies expertise, combining decades of mechanical advancement with computer-aided design to create robust, reliable solutions in building.

Understanding the profound impact of roll forming machinery can equip construction professionals with the knowledge needed to make informed decisions about resource allocation, design adaptation, and investment in new technology. Its role in enhancing both the aesthetic and functional aspects of modern architecture cannot be overstated, exemplifying a progressive leap in construction capabilities that continuously shapes the built environment we inhabit today.