In the heavy-duty transportation sector, efficiency, durability, and precision are paramount.

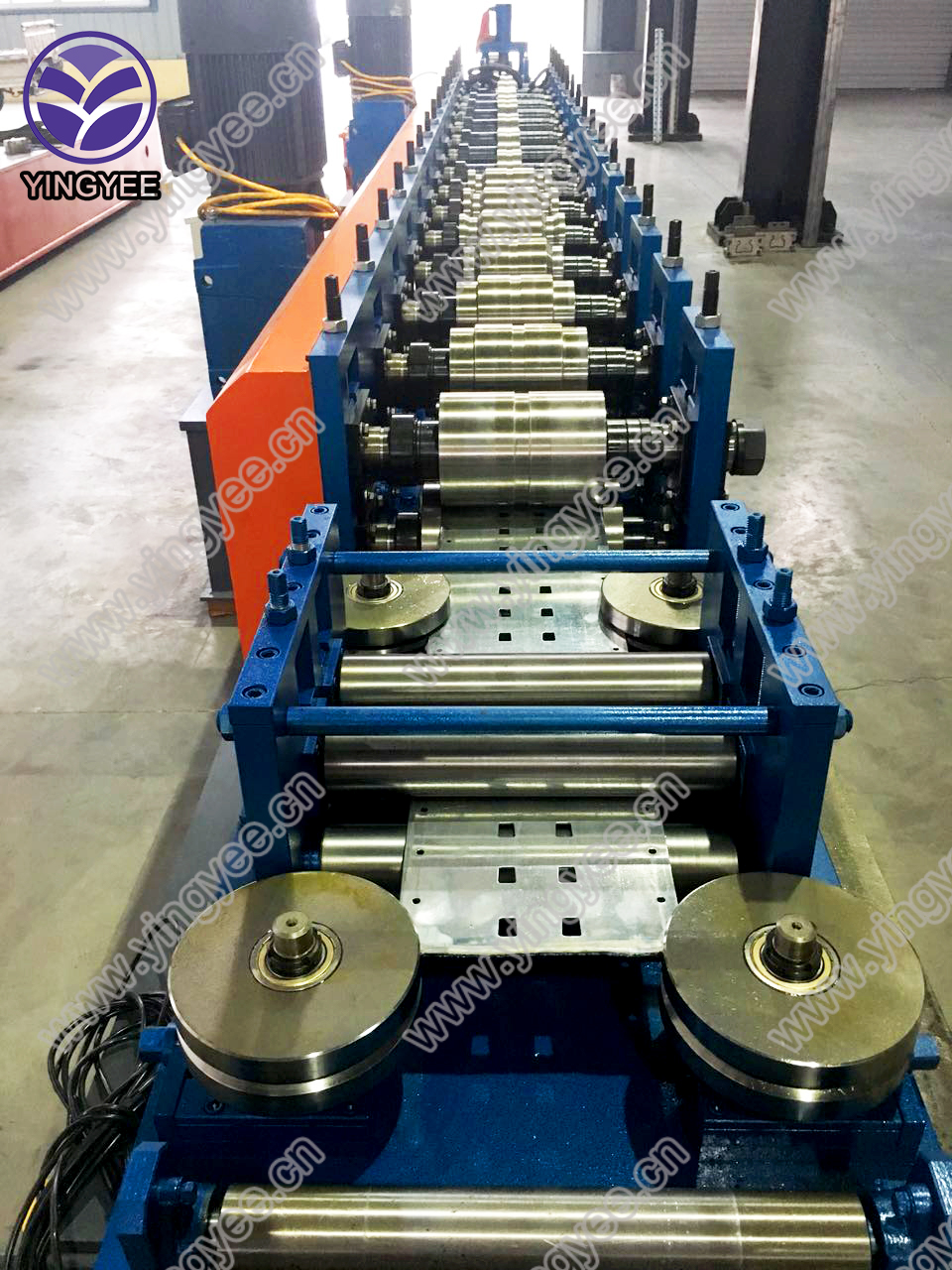

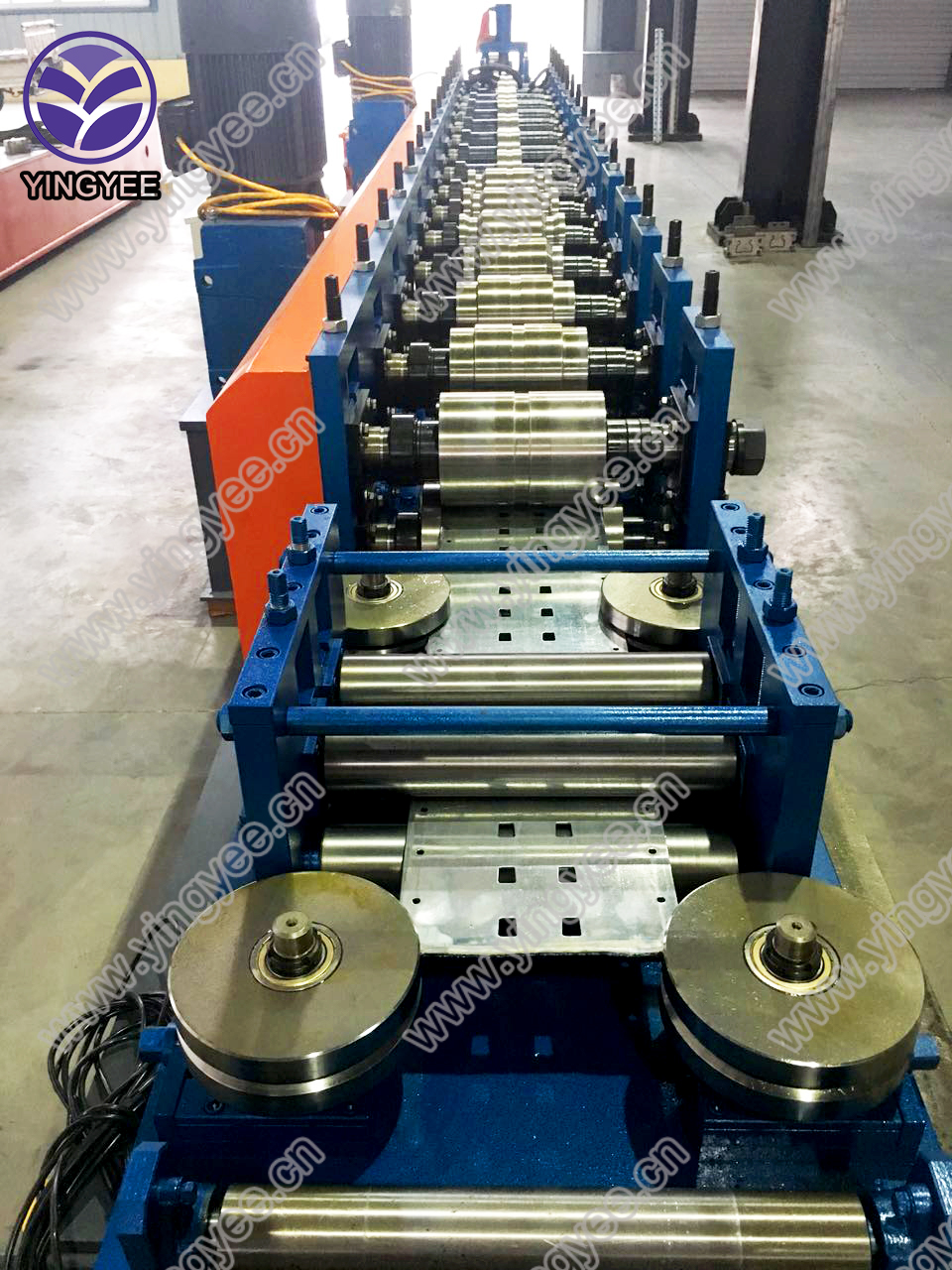

At the heart of these requirements lies an unsung hero the semi-truck fender cold bending machine. This specialized piece of equipment has revolutionized the way fenders are manufactured, providing an unmatched balance of performance and reliability for industry professionals.

For over a decade, semi-truck fender cold bending machines have been at the forefront of innovation in automotive manufacturing. Crafted to meet the rigorous demands of large-scale production, these machines utilize advanced cold bending technology—bringing multiple advantages to manufacturers and end-users alike. At its core, a semi-truck fender cold bending machine is engineered to produce high-quality fenders without the need for heat, ensuring material integrity and strength are maintained throughout the process. By eliminating the heating phase, the bending process significantly reduces the risk of weakening the metal, ensuring that the fenders can withstand the harsh conditions they will face on the open road.

The expertise embedded in the design of these machines is reflected in their precision engineering. They employ sophisticated hydraulic systems alongside computer-aided control mechanisms, allowing operators to execute bends with exact specifications. This precision minimizes waste and increases efficiency—critical considerations in both time management and cost-effectiveness for manufacturing plants. Beyond the operational efficiency, the machine's adaptability is noteworthy. Capable of handling various metals, sizes, and thicknesses, this equipment ensures that manufacturers can meet diverse customer needs without investing in multiple machines—a testament to its expertise in flexibility and capability.

Authoritativeness plays a vital role in choosing the right equipment, and the semi-truck fender cold bending machine does not disappoint. Leading brands in this market have set the standard for quality and performance, with years of research and development informing their capabilities. With input from mechanical engineers, automotive specialists, and industrial designers, these machines are built to fit seamlessly into manufacturing workflows, ensuring they meet industry standards and often exceed them. It's no surprise that they are trusted by large-scale manufacturers worldwide—those who cannot afford to compromise on quality and efficiency.

semi truck fender cold bending machine

The trustworthiness of these machines is derived from comprehensive testing and stringent quality control measures that they undergo before deployment. Each unit is subjected to a wide array of stress tests, ensuring that it can perform under various operating conditions, reflecting real-world scenarios. This commitment to excellence provides manufacturers with peace of mind, knowing that their investment is built to last and operate consistently.

In experience-based testimonials from industry veterans, the implementation of a semi-truck fender cold bending machine has resulted in measurable improvements in both productivity and fender quality. For instance, operators have noted reduced production times and a decrease in material wastage, which not only translates to cost savings but also contributes positively to environmental sustainability. Furthermore, maintenance teams have praised the durability and minimal upkeep these machines require—attributes that significantly reduce downtime and extend the lifespan of the equipment.

The future of automotive manufacturing is continually evolving, and equipment that embodies excellence, like the semi-truck fender cold bending machine, is leading the charge. Its role is not just to produce parts; it is a symbol of the cutting-edge technology that forms the backbone of modern manufacturing. By leveraging its capabilities, manufacturers are equipped to meet the ever-growing demands of the transport industry, ensuring that high standards of construction and efficiency are maintained.

In conclusion, the semi-truck fender cold bending machine stands as a pillar of innovation and reliability in the manufacturing sector. It gives businesses the tools needed to compete at the highest level, fostering an environment where quality and precision are the norms rather than the exception. This is more than machinery; it is an investment in quality assurance, operational excellence, and industry leadership.