In the landscape of industrial manufacturing, straight seam tube rolling mills represent a vital component, transforming raw metal into precise tubular shapes, key for a myriad of applications. As industries continue to demand efficiency and precision, understanding the nuanced design and operational intricacies of straight seam tube rolling mills becomes essential for stakeholders. This article delves into the multifaceted world of these machines, combining professional insights and authoritative evaluations to provide a comprehensive understanding of their capabilities and applications.

Straight seam tube rolling mills are engineered to produce high-quality welded tubes with continuous seams, ensuring uniformity and structural integrity. Their design philosophy revolves around efficiency and precision, harnessing advanced technologies to meet diverse industrial requirements. For professionals in the metal fabrication industry, selecting the right mill is paramount, and this decision is often influenced by factors such as material type, production volume, and desired dimensional accuracy.

Experience has shown that the efficiency of a straight seam tube rolling mill directly correlates with its technological sophistication. Mills equipped with automated control systems offer enhanced precision, reducing human error and improving throughput. These systems provide real-time monitoring and control, allowing operators to adjust parameters swiftly and maintain product consistency. Expertise in operating these advanced mills is crucial. Training programs and hands-on experience empower operators to maximize the potential of the technology, ensuring optimal performance and product quality.

From an expertise standpoint, choosing the correct parameters for rolling is critical. Variables such as roll diameter, seam orientation, and heat treatment processes impact the mechanical properties of the final product. Therefore, professionals involved in the design and operation of these mills must possess a deep understanding of metallurgy and material science. The ongoing evolution of materials, including high-strength alloys and lightweight metals, necessitates continuous learning and adaptation by those operating within this domain. Collaboration with metallurgists and engineers can further refine the production processes, leading to enhanced performance outcomes.

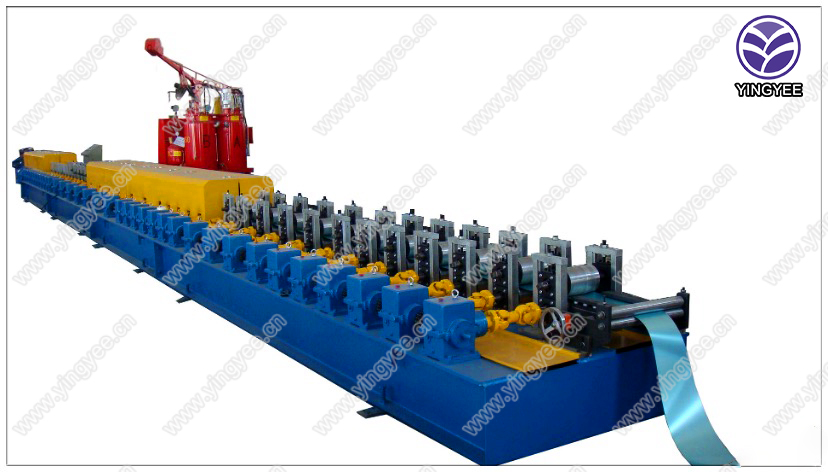

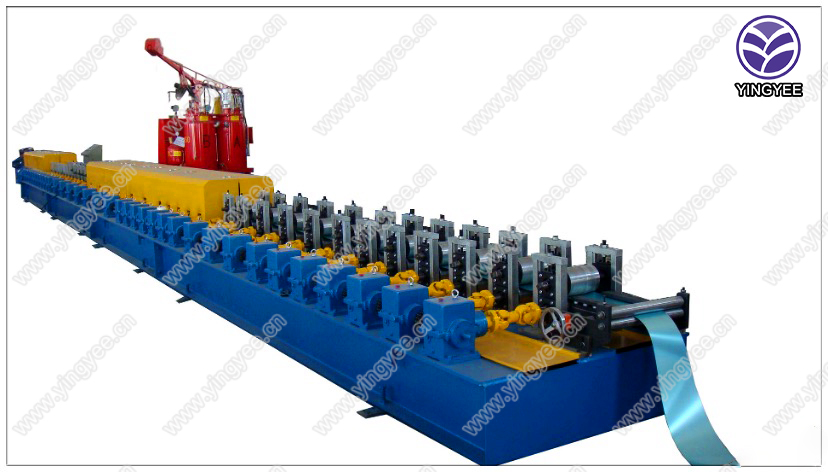

straight seam tube rolling mill

Authoritativeness in the realm of straight seam tube rolling mills stems from rigorous adherence to industry standards and certifications. These benchmarks are vital, assuring stakeholders of the machine's capability to deliver products that meet or exceed regulatory requirements. Standards such as ISO and ASTM provide guidelines for product quality and safety, fostering trust between manufacturers and their clients. Authoritative validation of a mill's operational excellence is best demonstrated through comprehensive quality control measures and third-party audits, reinforcing its credibility in the marketplace.

Trustworthiness is cultivated through transparency in operations and a steadfast commitment to quality assurance. Manufacturers of straight seam tube rolling mills who prioritize customer service, provide detailed product documentation, and offer robust after-sales support are viewed as more reliable. Building long-term relationships with clients by regularly updating equipment capabilities to accommodate new materials or production techniques further cements trust.

Reflecting on real-world applications, industries ranging from automotive to construction and energy rely heavily on the products crafted by straight seam tube rolling mills. The automotive sector, for instance, demands lightweight yet robust tubes for vehicle frames, where precision manufacturing ensures safety and performance. Similarly, in the energy industry, high-performance tubes are critical for pipelines and power installations, requiring exacting standards met consistently by these sophisticated machines.

In conclusion, mastering the operation and precision of straight seam tube rolling mills is more than a technical challenge; it's a commitment to excellence in manufacturing. By integrating cutting-edge technology, maintaining stringent quality controls, and upholding global standards, manufacturers can offer products that not only meet but exceed client expectations. As industries evolve, so too must the capabilities of these mills, ensuring they continue to serve as the backbone of modern manufacturing with unwavering trust and authority.