The Straight Seam Tube Rolling Mill An Overview

The straight seam tube rolling mill is a specialized manufacturing equipment used predominantly in the production of straight seam electric resistance welded (ERW) tubes. This process is essential in various industries, including construction, automotive, and energy. The core operation of the mill involves forming flat steel strips into tubes and then welding them along the seam to create strong, durable pipes.

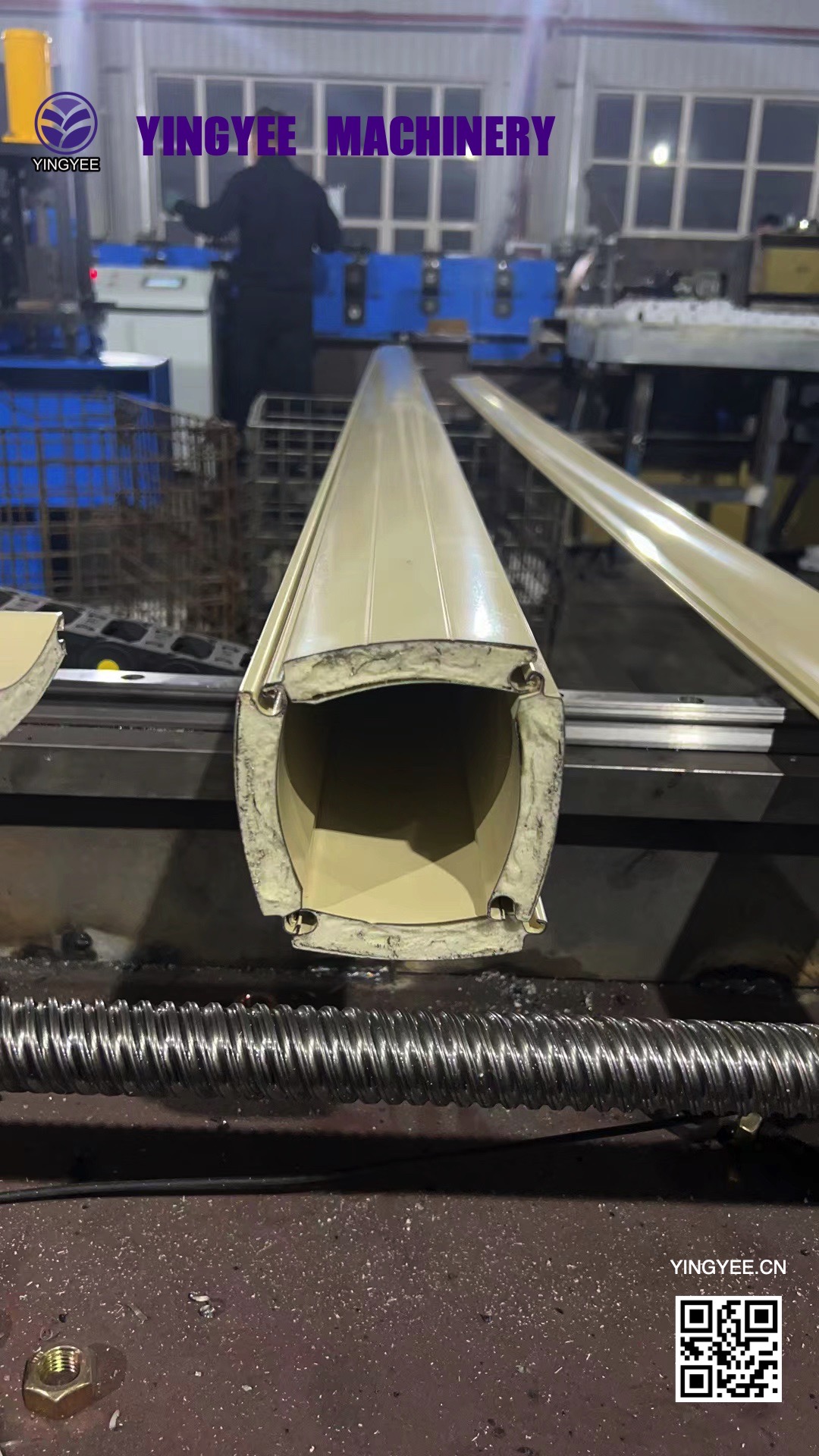

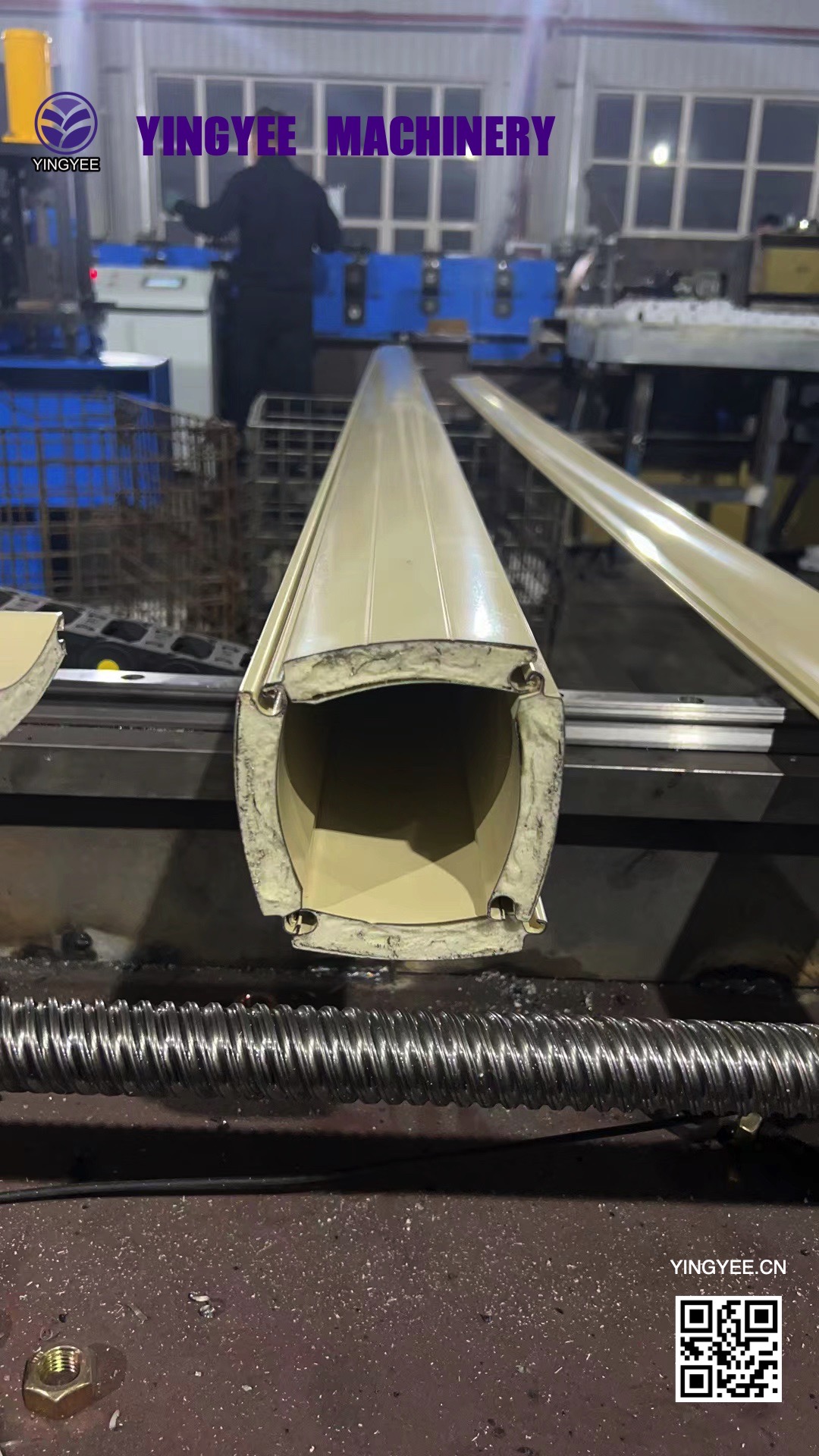

The process typically begins with a coil of flat steel, which is fed into the mill. The initial phase involves shaping the steel strip into a cylindrical form using a series of rollers. These rollers are meticulously designed to ensure precise control over the tube dimensions, including diameter and wall thickness. As the strip progresses through the mill, it undergoes a series of rolling and forming operations that gradually transform it into a tube.

Once the cylindrical shape is achieved, the edges of the strip are aligned and heated to a specific temperature using induction or contact heating methods. This is crucial, as it prepares the metal for welding. The welding process, which occurs at the seam, is primarily facilitated by electric resistance welding. In this process, an electric current is passed through the edges of the tube, generating heat that fuses them together. This method is favored for its speed, efficiency, and ability to produce high-quality welds.

straight seam tube rolling mill

One of the significant advantages of using a straight seam tube rolling mill is its efficiency in mass production. The continuous nature of the process allows for high output with minimal downtime, making it economically advantageous. Additionally, the resulting tubes exhibit excellent mechanical properties, making them suitable for a wide range of applications.

Furthermore, advancements in technology have led to the development of sophisticated control systems that monitor various parameters throughout the rolling process. This integration of automation enhances product consistency and quality, reducing the risk of defects.

In conclusion, the straight seam tube rolling mill plays a vital role in modern manufacturing, providing an efficient method for producing high-quality welded tubes. As industries continue to evolve, the importance of such technology in meeting the demands for durable and reliable materials will only increase, solidifying the mill's position as a cornerstone of metal fabrication.