In the rapidly evolving landscape of industrial machinery, the storage rack shelf frame roll forming machine stands as a testament to technological advancement and efficiency. As an integral part of modern manufacturing,

these machines have transformed the way shelf frames are produced, providing unmatched precision and productivity. This article delves into the nuanced experience of using these machines, their expert design mechanics, authoritative market presence, and the trust they inspire among industrial manufacturers.

The experience of operating a storage rack shelf frame roll forming machine is one marked by seamless efficiency and remarkable precision. Users frequently report a significant reduction in manual labor and an increase in output quality. These machines are engineered to handle various metal gauges and profiles, allowing them to produce shelf frames that meet exact specifications with minimal error. Their intuitive control systems make it easy for operators to manage production runs, adjust settings, and monitor outputs in real-time, thereby enhancing the overall manufacturing experience.

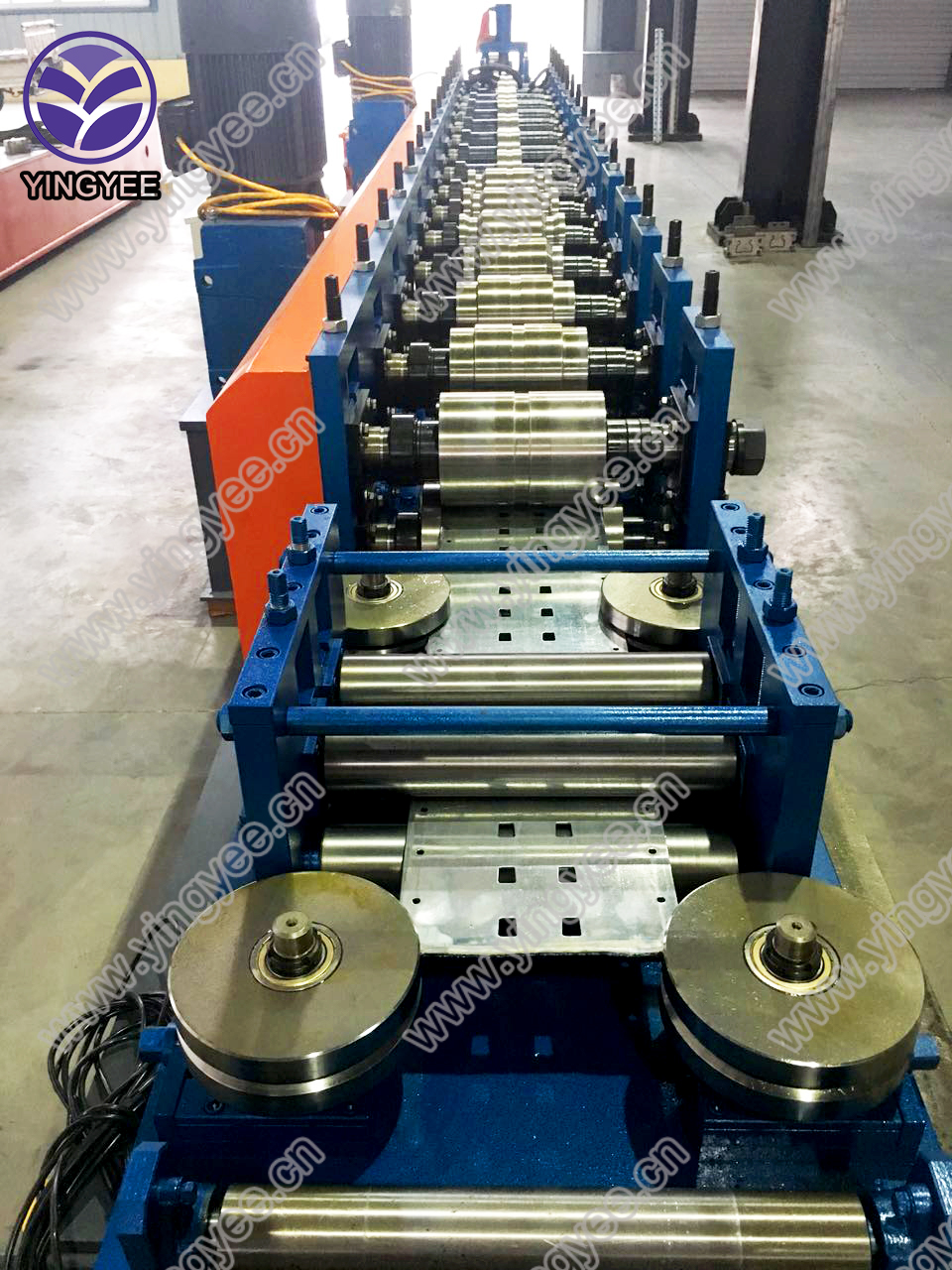

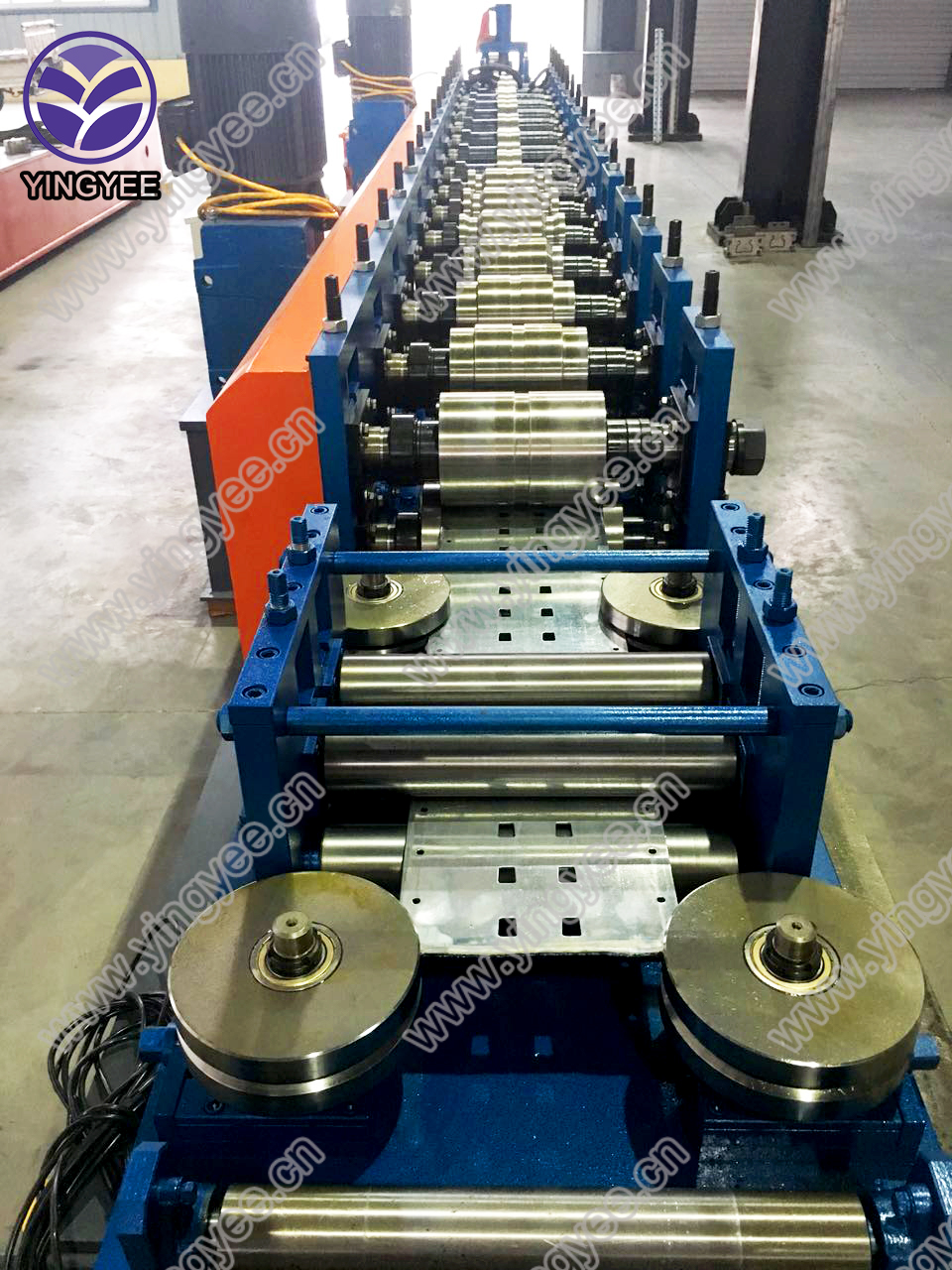

From a professional standpoint, the expertise embedded in the design of these machines is unparalleled. They incorporate advanced roll forming technology, which uses successive sets of rolls to shape metal without altering its thickness. This process not only ensures high-quality outcomes but also reduces material waste significantly. The machinery is equipped with state-of-the-art features like programmable logic controllers (PLCs) and automation capabilities that streamline production processes, minimize downtime, and optimize efficiency. Such technological prowess underscores the machine’s role as a cornerstone in the assembly of durable and robust storage solutions.

storage rack shelf frame roll forming machine

In the competitive arena of industrial machinery, the storage rack shelf frame roll forming machine commands authority. Its widespread adoption across manufacturing plants globally is a testament to its performance reliability and cost-effectiveness. Manufacturers recognize the machine's ability to consistently deliver precise and sturdy frame components, which are essential for building resilient storage systems. This authoritative presence is bolstered by continuous advancements in machinery design and functionality, setting the standard for future innovations in roll forming technology.

Moreover, trust in the storage rack shelf frame roll forming machine is built on a foundation of proven performance and reliability. Manufacturers who invest in these machines do so with the confidence that they are acquiring equipment that will deliver consistent results. The machines are often subject to rigorous testing and quality assurance processes, ensuring they meet international safety and performance standards. Consequently, this engenders a level of trust that is crucial for businesses dependent on long-term equipment reliability and efficiency.

In conclusion, the storage rack shelf frame roll forming machine is an epitome of engineering brilliance, offering a blend of experience, expertise, authority, and trustworthiness. Its cutting-edge technology and user-friendly design make it a vital asset in the production of storage solutions. For manufacturers aiming to enhance their production capabilities and product quality, investing in such a machine is not just a strategic choice but a commitment to excellence and innovation. With continued advancements, these machines are poised to redefine the future of shelf frame manufacturing, solidifying their status as indispensable tools in industrial production.