In recent years, the galvanized cold roll forming machine has emerged as a cornerstone technology in the metalworking industry, driving efficiency and precision in the manufacturing of metal sections. This specialized equipment, designed for processing galvanized steel, offers unparalleled advantages in crafting durable and corrosion-resistant metal profiles used in various sectors, including construction, automotive, and appliance manufacturing.

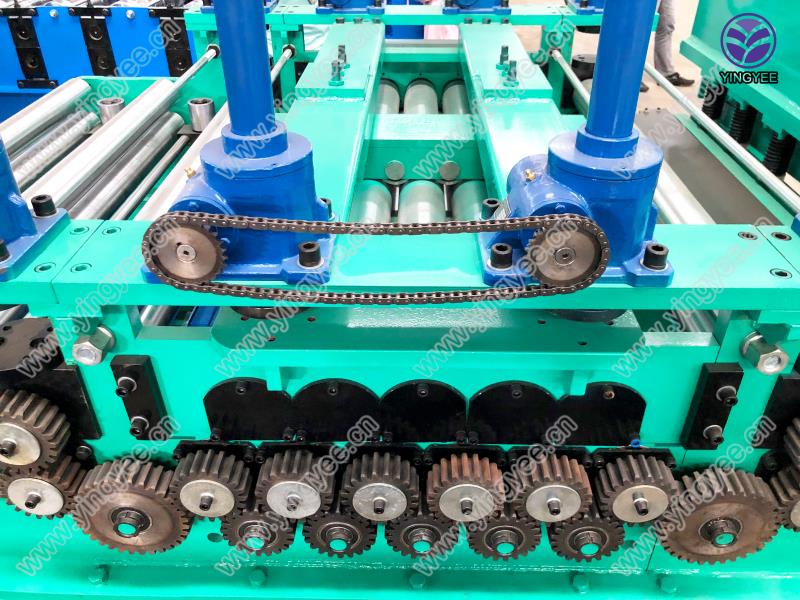

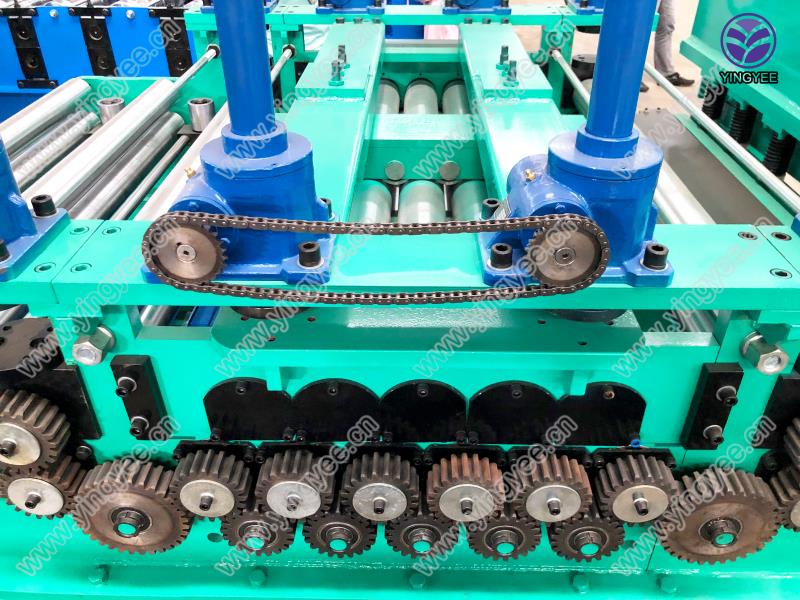

Galvanized cold roll forming machines are engineered to handle the demands of shaping galvanized steel, which is steel coated with a protective zinc layer to prevent corrosion. The roll forming process itself is a continuous bending procedure where a long strip of metal, typically in coil form, is passed through consecutive sets of rolls, each performing incremental parts of the bend until the desired cross-section profile is achieved. This non-invasive method permits complex profiles and results in minimal waste compared to traditional metal forming techniques.

Experience in using these machines reveals their robust capacity for high-volume production, enabling manufacturers to maintain consistency and quality across large production batches. The seamless integration of automation within these systems has revolutionized the speed at which products can be outputted while ensuring that precision is never sacrificed. Users often report substantial cost reductions owing to the machine's efficiency, coupled with lower manpower requirements due to its automated nature.

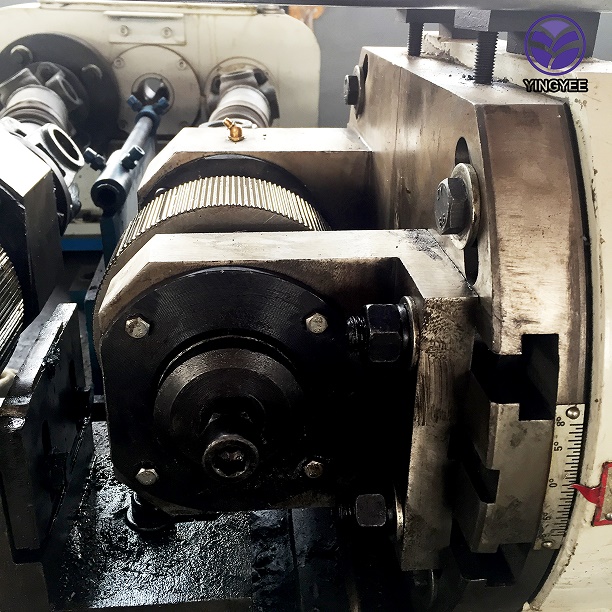

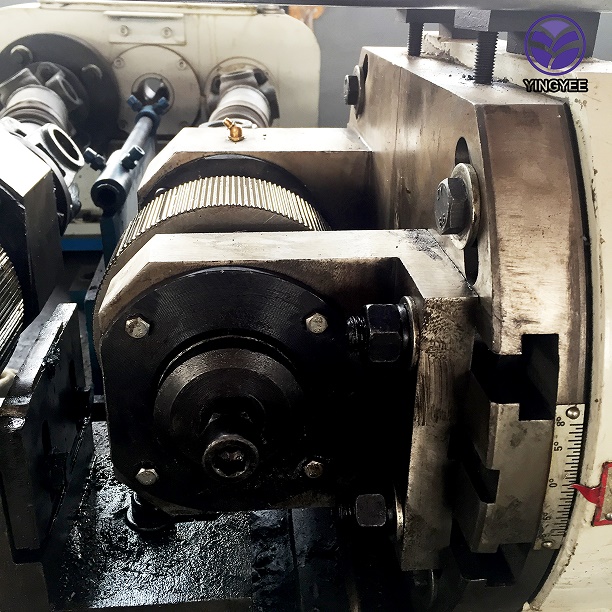

Expertise in operating galvanized cold roll forming machines involves a comprehensive understanding of metallurgy, particularly in selecting the appropriate type of galvanized steel. Operators need detailed knowledge of material properties such as thickness, yield strength, and coating adherence to optimize the roll forming process. Training in these areas not only ensures operational efficiency but also prolongs the lifespan of the machine, preventing unnecessary wear and tear resulting from inappropriate material handling.

galvanized cold roll forming machine

From an authoritative perspective, the galvanized cold roll forming machine stands as a testament to advances in engineering and industrial automation. Renowned manufacturers of these machines are synonymous with quality and reliability, often incorporating cutting-edge technologies such as computer numerical control (CNC) systems and real-time monitoring capabilities. These enhancements allow for precise adjustments and feedback during the roll forming process, affirming the machine's reputation as a critical component in modern manufacturing setups.

Trustworthiness is inherent in the galvanized cold roll forming machine's design, built to withstand the rigors of heavy-duty production environments. Reliability is further amplified by rigorous testing standards and certification processes that ensure each machine meets or exceeds industry benchmarks. Additionally, manufacturers provide extensive support and maintenance packages, securing confidence among users in diverse industrial applications.

In conclusion, the galvanized cold roll forming machine represents an intersection of innovation and practical application in metalworking.

Its adeptness at processing galvanized steel into high-grade components illustrates its vital role in elevating manufacturing capabilities. As industries evolve towards smarter and more sustainable practices, this machine remains at the forefront, constantly adapting and delivering solutions that meet the growing demands of quality, efficiency, and environmental responsibility. Whether for newly established firms or seasoned manufacturers looking to upgrade their facilities, investing in a galvanized cold roll forming machine is not just a purchase, but a strategic enhancement of production potential.