Steel Long Span Roof Roll Forming Machine An Overview

The construction industry has witnessed significant advancements in technology, particularly in manufacturing processes. One such advancement is the steel long span roof roll forming machine, which has revolutionized the way roofing materials are produced. This machine plays a crucial role in the fabrication of steel roofing sheets that are not only durable but also efficient in covering large areas seamlessly.

Understanding Roll Forming

Before diving into the specifics of the steel long span roof roll forming machine, it’s essential to understand the roll forming process. Roll forming involves the continuous bending of metal strips through a series of rollers, resulting in desired shapes and profiles. This method is highly efficient, allowing for mass production of uniform components with minimal material wastage.

The Design and Functionality of the Machine

A steel long span roof roll forming machine is specifically designed to manufacture roof panels that can extend over larger spans compared to traditional roofing. The machine typically consists of several key components, including a decoiler, forming rollers, cutting unit, and a control system.

1. Decoiler The process begins with a decoiler that feeds the flat steel coil into the machine. The decoiler unwinds the coil and ensures a steady flow of material for the forming process.

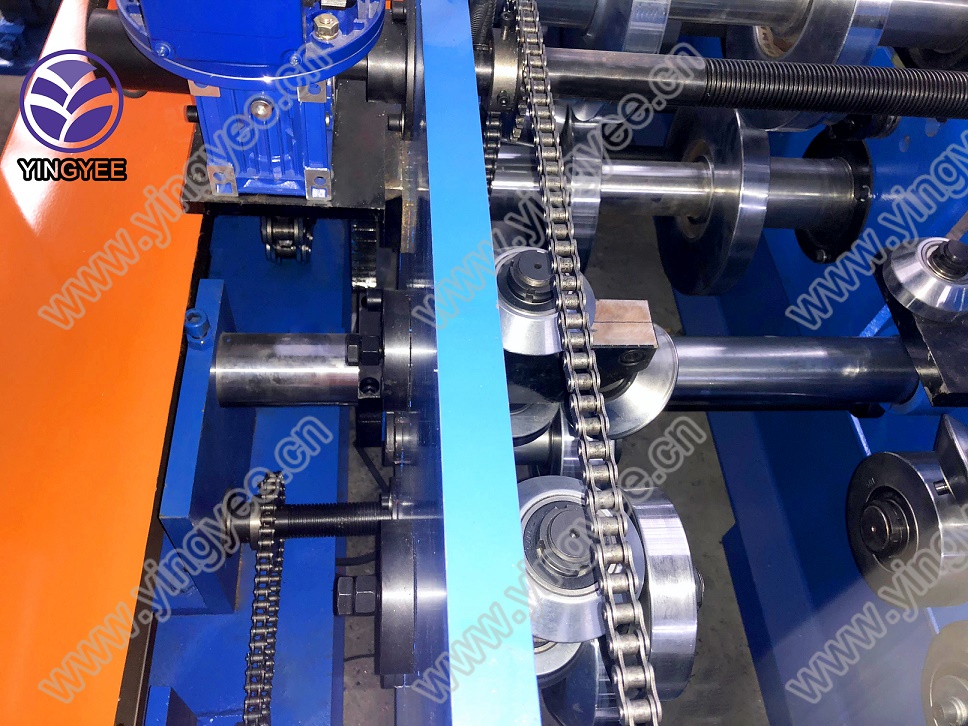

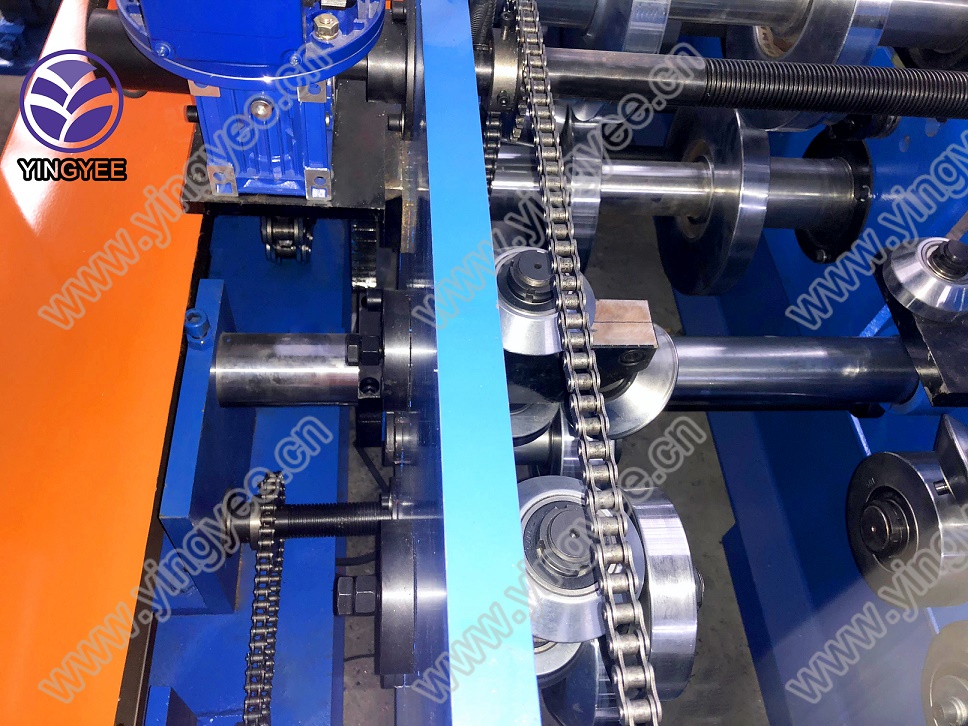

2. Forming Rollers The heart of the machine lies in its set of rollers. These rollers are meticulously designed to progressively shape the metal sheet into desired profiles, such as V-trough, trapezoidal, or U-shaped panels. The rollers control the material's thickness and can handle various steel grades, enhancing the versatility of the machine.

3. Cutting Unit Once the roofing profile is formed, the sheet needs to be cut to specific lengths. A cutting unit, which is generally a hydraulic or mechanical shear, is integrated into the system to ensure precise and clean cuts, adjusting to different panel sizes as required.

steel long span roof roll forming machine

4. Control System Modern machines come equipped with advanced control systems that allow for easy operation and monitoring of the forming process. These systems help in adjusting settings such as speed, cutting length, and even the profile type with minimal downtime.

Advantages of Steel Long Span Roof Roll Forming Machines

1. Efficiency The roll forming process is continuous, making it faster than traditional roofing methods. This efficiency translates into lower labor costs and quicker project completion times.

2. Durability Steel roofing produced by these machines is resilient against harsh weather conditions, ensuring longevity and reduced maintenance costs.

3. Aesthetic Variety The versatility of the machine allows for various profile shapes and finishes, enabling architects and builders to choose options that best suit their aesthetic and functional requirements.

4. Reduced Waste The precision of the roll forming process minimizes material wastage, making it an environmentally friendly choice in construction.

Conclusion

The steel long span roof roll forming machine is a vital innovation that caters to the ever-growing demands of the construction industry. With its ability to produce high-quality, durable roofing materials efficiently, it has become a go-to choice for contractors and builders worldwide. As technology continues to advance, these machines are likely to evolve, further enhancing their capabilities and the quality of materials they produce. For anyone in the construction business, understanding and utilizing this technology can lead to significant advantages in terms of productivity, cost savings, and overall project success.