The Evolution and Significance of the Steel Strut Channel Roll Forming Machine

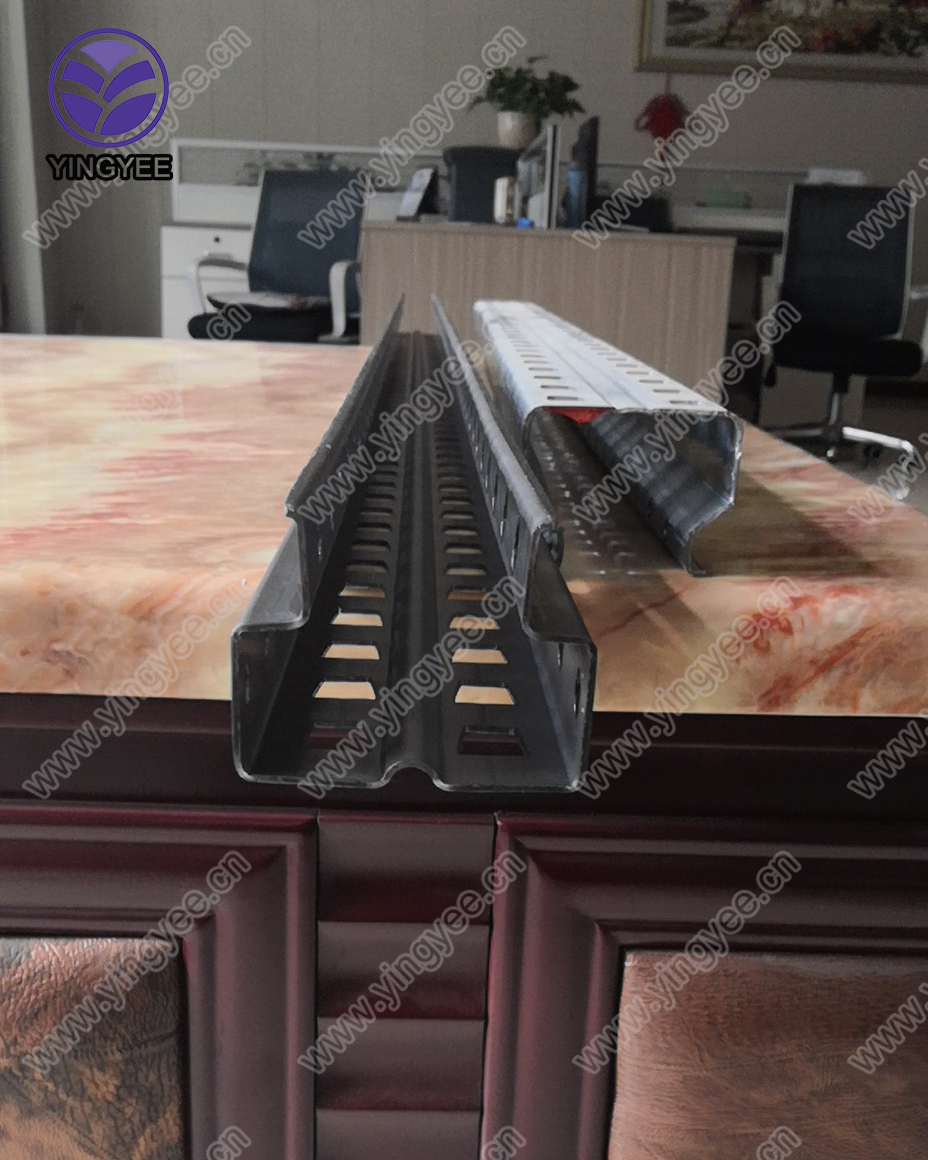

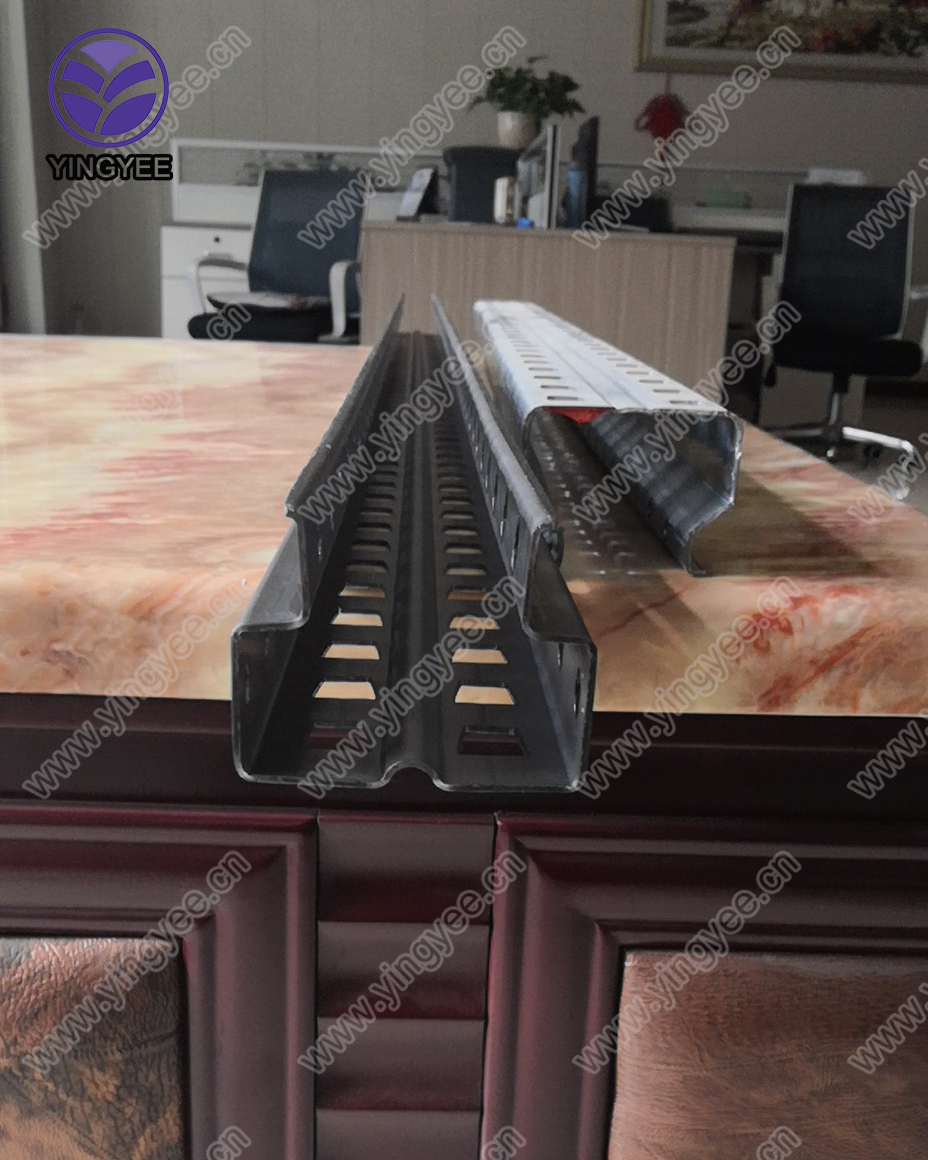

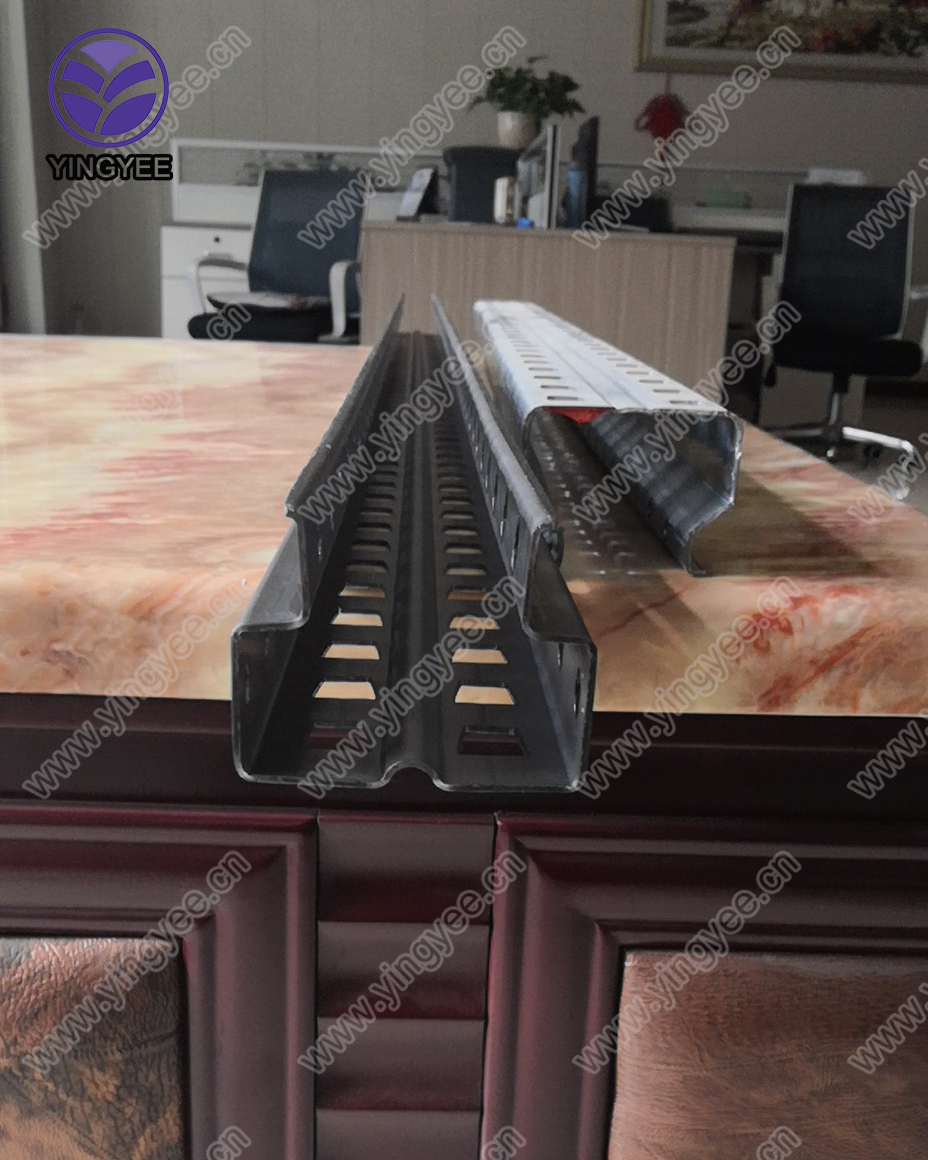

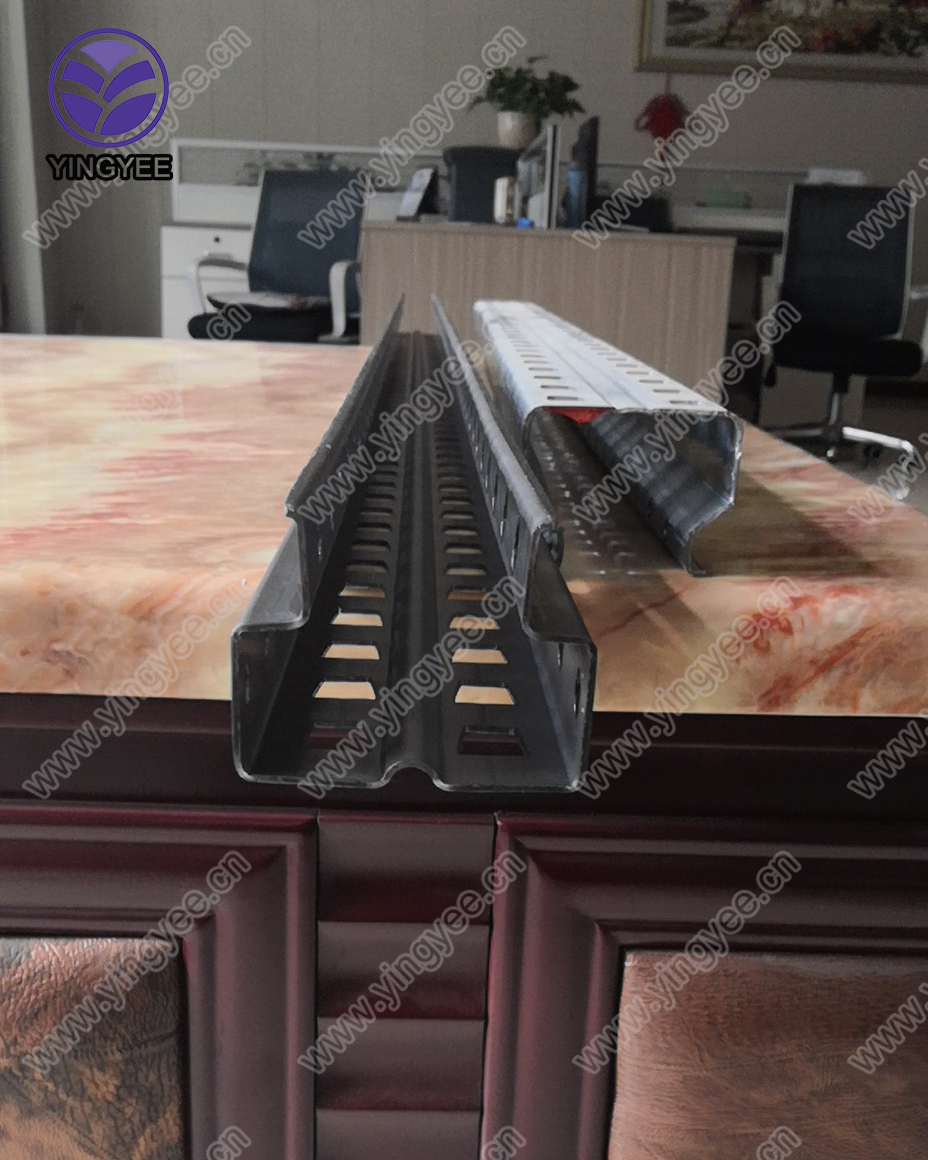

The steel strut channel roll forming machine is a technological marvel that has revolutionized the construction industry. This machine is designed to manufacture steel strut channels, which are widely used in various construction projects. The process of roll forming involves passing a sheet of metal through a series of rollers, each one shaping the material into a specific profile. In this case, the profile is a steel strut channel, which is characterized by its high strength, durability, and versatility.

The development of the steel strut channel roll forming machine can be traced back to the early days of industrialization when manual labor was replaced by mechanized processes. The initial machines were rudimentary and could only produce simple profiles. However, with advancements in technology and materials science, these machines have evolved into sophisticated equipment capable of producing complex shapes with precision and consistency.

One of the key advantages of using a steel strut channel roll forming machine is its ability to produce long lengths of material without any seams or joints. This seamless production ensures that the final product is structurally sound and free from weaknesses that could compromise its integrity. Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications

Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications

steel strut channel roll forming machine

steel strut channel roll forming machine.

Another significant benefit of the steel strut channel roll forming machine is its efficiency. Compared to traditional methods such as welding or cutting, roll forming is much faster and requires less energy consumption. This not only reduces production costs but also minimizes waste, making it an environmentally friendly option. Furthermore, the accuracy of the roll-forming process ensures that there is minimal material waste during production.

In conclusion, the steel strut channel roll forming machine plays a crucial role in modern construction projects by providing strong, durable, and versatile materials for various applications. Its ability to produce seamless channels efficiently and accurately has made it an essential tool for manufacturers worldwide. As technology continues to advance, we can expect further improvements in the design and functionality of these machines, making them even more valuable to industries that rely on high-quality steel strut channels.

Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications

Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications Additionally, the roll-forming process allows for customization, enabling manufacturers to create channels with varying widths, heights, and thicknesses to suit specific applications steel strut channel roll forming machine.

Another significant benefit of the steel strut channel roll forming machine is its efficiency. Compared to traditional methods such as welding or cutting, roll forming is much faster and requires less energy consumption. This not only reduces production costs but also minimizes waste, making it an environmentally friendly option. Furthermore, the accuracy of the roll-forming process ensures that there is minimal material waste during production.

In conclusion, the steel strut channel roll forming machine plays a crucial role in modern construction projects by providing strong, durable, and versatile materials for various applications. Its ability to produce seamless channels efficiently and accurately has made it an essential tool for manufacturers worldwide. As technology continues to advance, we can expect further improvements in the design and functionality of these machines, making them even more valuable to industries that rely on high-quality steel strut channels.

steel strut channel roll forming machine.

Another significant benefit of the steel strut channel roll forming machine is its efficiency. Compared to traditional methods such as welding or cutting, roll forming is much faster and requires less energy consumption. This not only reduces production costs but also minimizes waste, making it an environmentally friendly option. Furthermore, the accuracy of the roll-forming process ensures that there is minimal material waste during production.

In conclusion, the steel strut channel roll forming machine plays a crucial role in modern construction projects by providing strong, durable, and versatile materials for various applications. Its ability to produce seamless channels efficiently and accurately has made it an essential tool for manufacturers worldwide. As technology continues to advance, we can expect further improvements in the design and functionality of these machines, making them even more valuable to industries that rely on high-quality steel strut channels.