Understanding Standing Seam Bending Tools A Comprehensive Overview

Standing seam roofing systems are renowned for their durability, weather resistance, and aesthetic appeal. These systems consist of interlocking metal panels that create a weathertight seal, making them popular in both residential and commercial construction. However, the installation of these roofs requires specialized tools, particularly standing seam bending tools, which are crucial in achieving precise bends and curves in the metal panels.

The Importance of Standing Seam Bending Tools

Standing seam bending tools are essential for fabricators and installers as they allow for the accurate shaping of metal panels. The bending process is critical since even minor inaccuracies can lead to water leaks, structural weaknesses, and longevity issues. Properly bent panels ensure a perfect fit and a clean, professional appearance, enhancing the overall performance of the roofing system.

These tools come in various forms, ranging from hand-held tools to more advanced machinery, such as brake machines and rotary bending tools. Each tool serves its specific purpose, catering to different sizes and types of metal panels.

Types of Standing Seam Bending Tools

1. Hand Tools For smaller projects or DIY enthusiasts, hand tools like bending jigs or manual seamers are practical. These tools allow for manual bending of metal panels and can be used in sites with limited space. They require a certain level of skill and experience to operate effectively, making them suitable for simpler, less demanding applications.

2. Power Tools Electric or pneumatic tools offer higher precision and efficiency than hand tools. Powered seamers and automated bending machines can handle larger panels with less manual effort, making them ideal for commercial projects. These tools can significantly speed up the installation process, allowing for quicker project completion times.

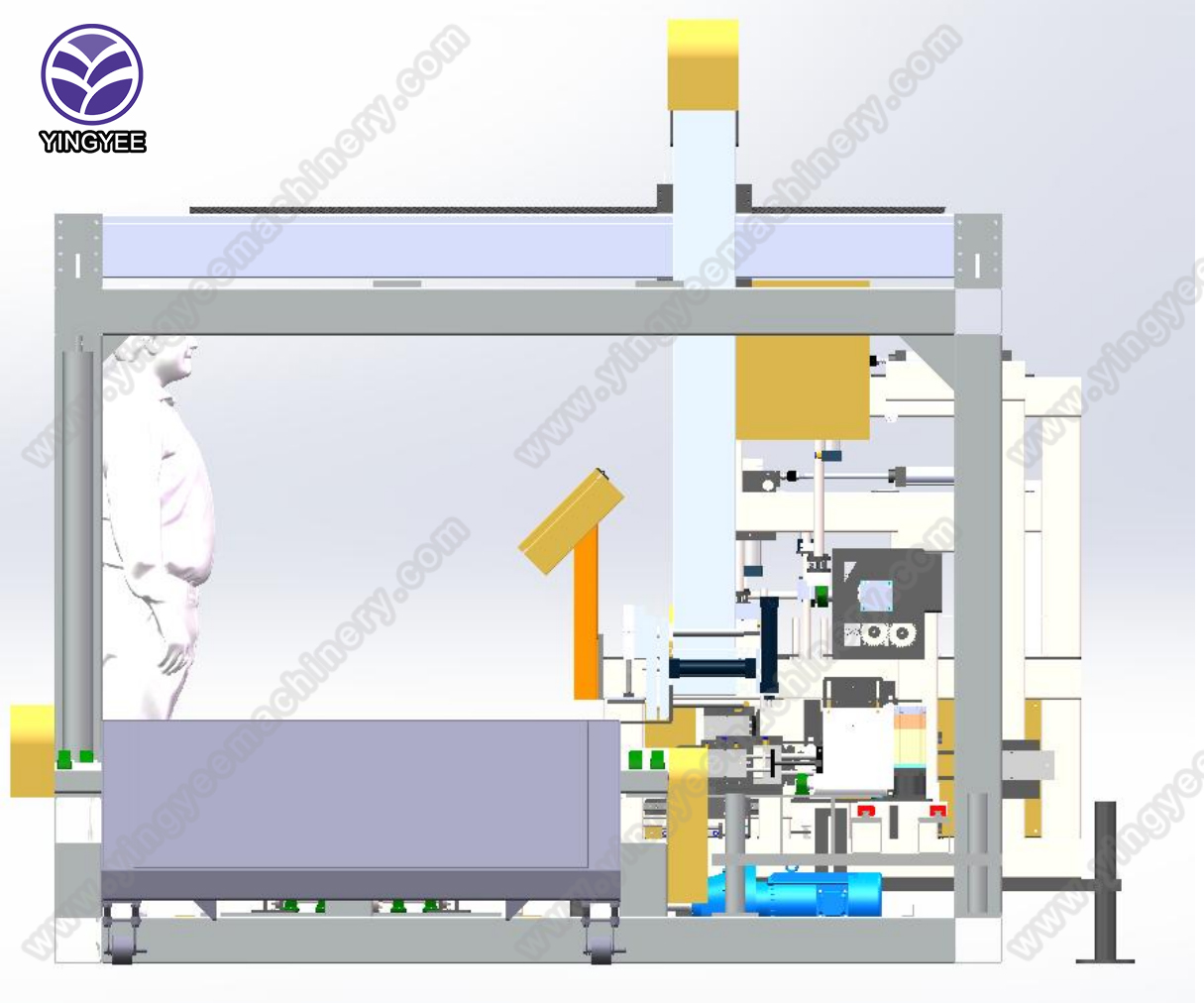

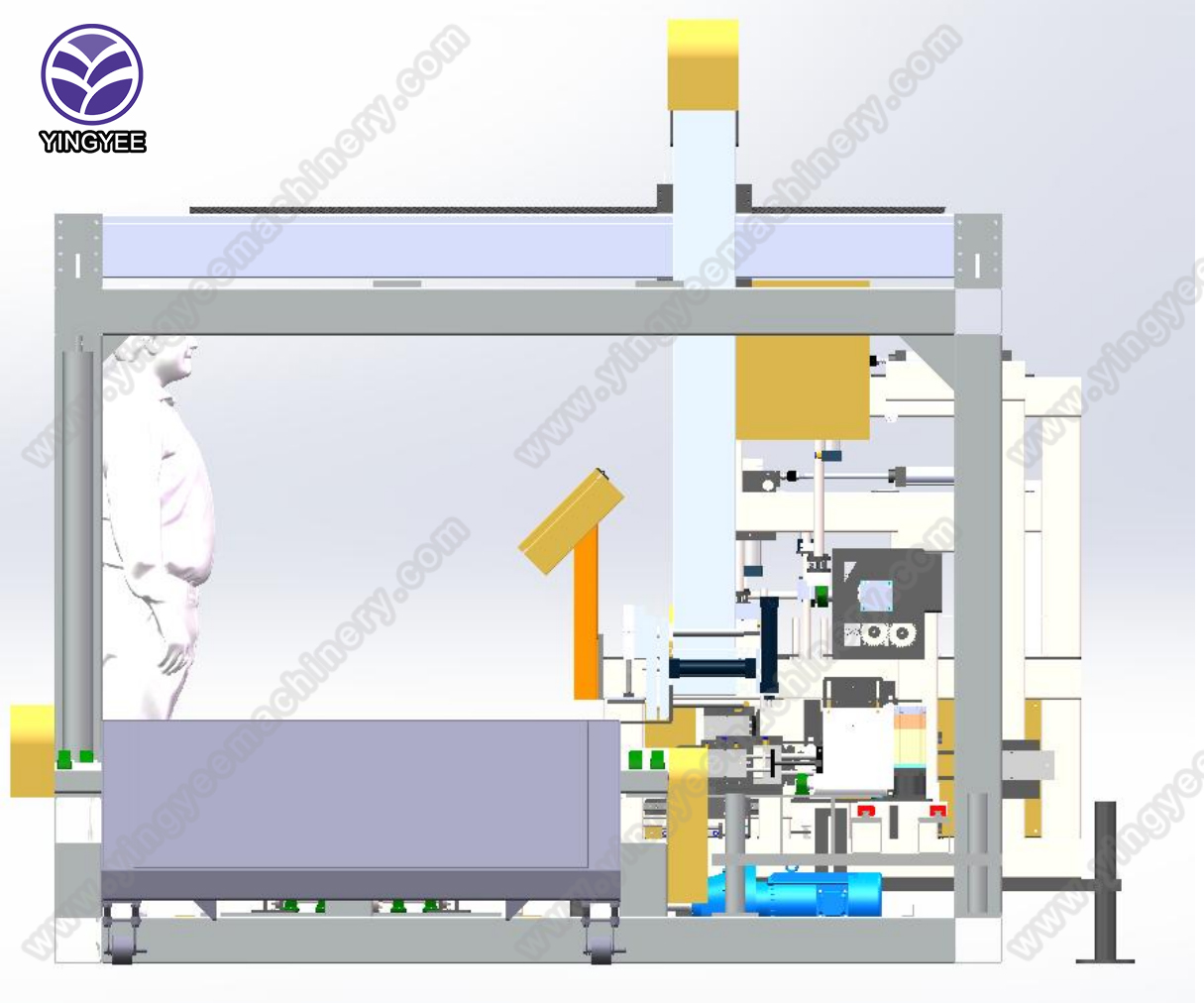

standing seam bending tool

3. Brake Machines A brake machine is a common tool in the metalworking industry designed to bend and shape metal sheets accurately. These machines can create specific angles and shapes required for standing seam roofing. Some advanced models are equipped with digital controls for precise measurements, ensuring consistency and quality in each bend.

4. Rotary Benders For more complex architectural designs, rotary benders can create curves and unique shapes in metal panels. This flexibility is essential in modern design trends where aesthetics play a significant role. Rotary bending tools enable fabricators to produce panels that fit complex rooflines, maintaining both functionality and beauty.

Choosing the Right Tool

Selecting the appropriate bending tool depends on several factors, including project size, material type, and specific design requirements. For example, larger commercial projects might benefit from advanced brake machines, while smaller residential jobs could be efficiently managed with handheld tools. It is essential to assess the project’s scope and the contractor’s skill level when choosing the right equipment.

Maintaining Your Bending Tools

Like any specialized equipment, maintaining standing seam bending tools is crucial for their longevity and performance. Regular cleaning, lubrication, and inspection for wear are necessary practices that help prevent malfunctions during the bending process. Additionally, operators should be trained in proper handling techniques to minimize the risk of damage or accidents.

Conclusion

Standing seam bending tools are an integral part of any metal roofing project, enabling the precise fabrication and installation of panels. With a variety of tools available, from simple hand-held options to advanced machinery, contractors can choose equipment that best suits their project needs. Understanding how to utilize and maintain these tools effectively can lead to perfectly crafted roofing systems, ensuring both durability and aesthetics. Whether for a professional installation or a DIY endeavor, investing in the right standing seam bending tools is essential for success in the world of metal roofing.